Garlic clove-separating rotary machine

A technology for splitting and garlic, which is applied in application, food processing, food science, etc., can solve the problems of poor splitting effect, difficult positioning effect of garlic bulbs, and low splitting efficiency, so as to improve the splitting effect and use Good effect, good split effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

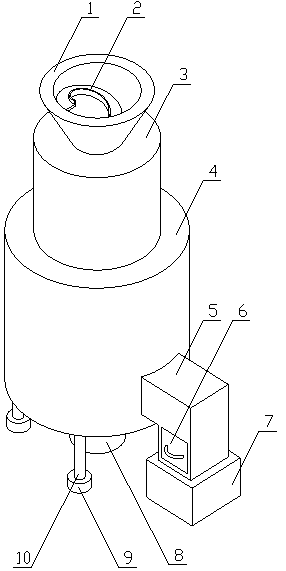

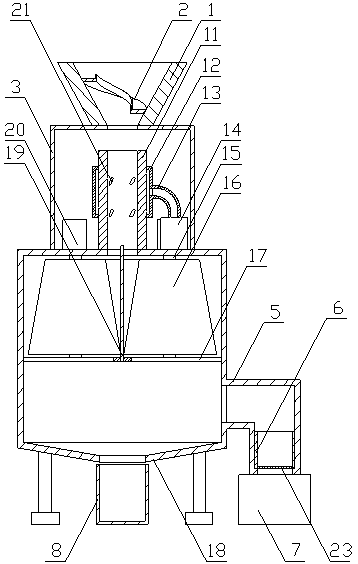

[0029]A rotary garlic splitting machine of the present invention is realized in this way. It consists of a main collecting device and a splitting device. The main collecting device consists of a guide hopper (1), a guide slide (2), a connecting cylinder (3), and a splitting cylinder ( 4), exhaust pipe (5), collection box (6), first air pump (7), garlic collecting bucket (8), cushioning foot pad (9), support foot (10), and blanking funnel (18) and filter screen (23), the bottom of the split cylinder (4) is an open structure, the blanking funnel (18) is placed at the bottom of the split cylinder (4), and the height of the blanking funnel (18) is from the middle Gradually increasing towards the edge, there is a garlic dropping groove in the middle of the dropping funnel (18), and the garlic collecting barrel (8) is placed at the center of the bottom of the feeding funnel (18), and communicates with the dropping garlic groove correspondingly, the The bottom of the blanking funnel ...

Embodiment 2

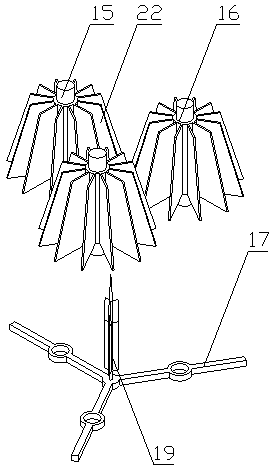

[0032] The difference between this embodiment and Embodiment 1 is: the outer edge of the auxiliary sharp plate (25) is arc-shaped, and the width of the auxiliary sharp plate (25) gradually increases from top to bottom; when in use, when the garlic falls, The auxiliary sharp plate (25) is more convenient to be inserted into the gap of the garlic clove, and then better assists the insertion of the auxiliary plate (26);

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is: the auxiliary plate (26) is provided with a plurality of chute (27), and the chute (27) extends obliquely downward; when in use, it can prevent the garlic from splitting The roller (16) moves upward under the rubbing to improve the splitting effect;

[0035] The height of the dropping funnel (18) is designed to gradually increase from the middle to the edge, enabling the garlic cloves to slide down the slope of the dropping funnel (18) into the garlic collecting bucket (8);

[0036] The diameter of the guide hopper (1) is designed to gradually decrease from top to bottom, and the mouth of the guide hopper (1) is relatively large, which is convenient for putting garlic in;

[0037] The guide slide (2) is designed with a spiral structure, which can make the garlic slide downwards along the guide slide (2) to prevent the garlic from falling directly downward;

[0038] The inner edge of the guide slide (2) is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com