Submersed nozzle capable of reducing nozzle clogging

An immersion and nozzle technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of reducing nozzle blockage, molten steel speed difference, backflow, etc., and achieve the effect of reducing nozzle blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

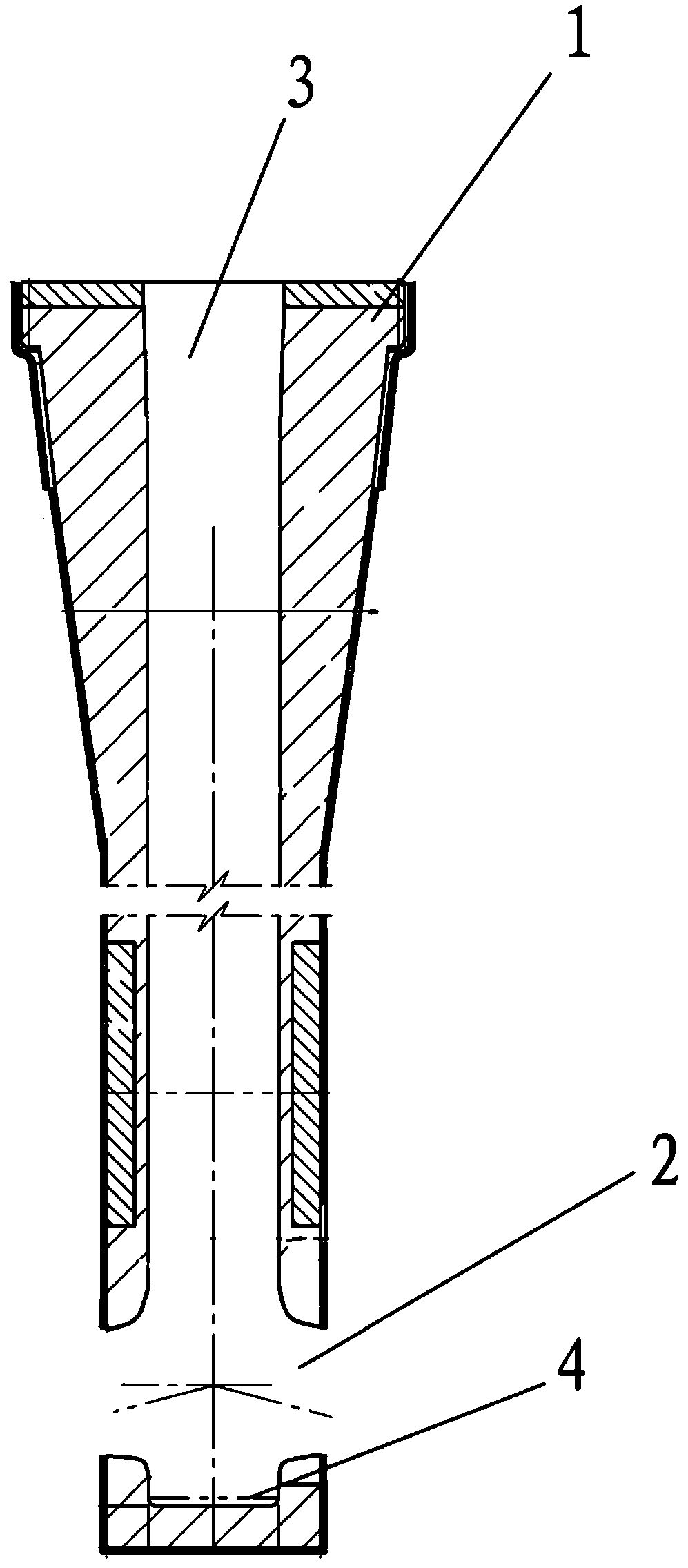

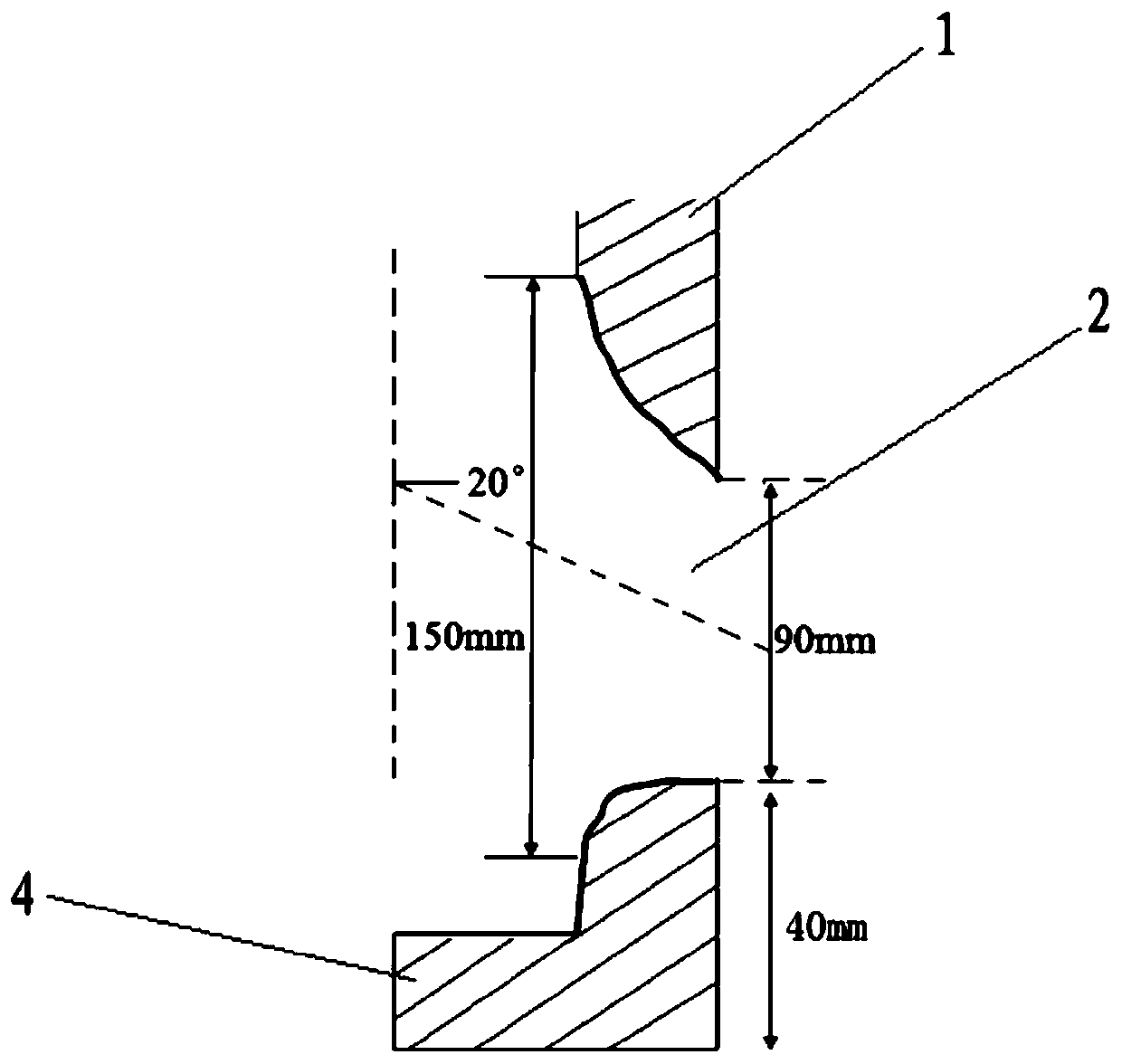

[0017] The embodiment of the present invention provides a submerged nozzle that can reduce nozzle blockage, which solves the problem that in the prior art, molten steel will flow out from the lower edge of the tapping hole, causing the flow velocity of the upper and lower molten steel in the crystallizer to have a certain speed. Poor, even in some cases, a certain technical problem of backflow will be formed on the outlet of the submerged nozzle, and the technical effect of reducing the blockage of the nozzle is achieved.

[0018] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

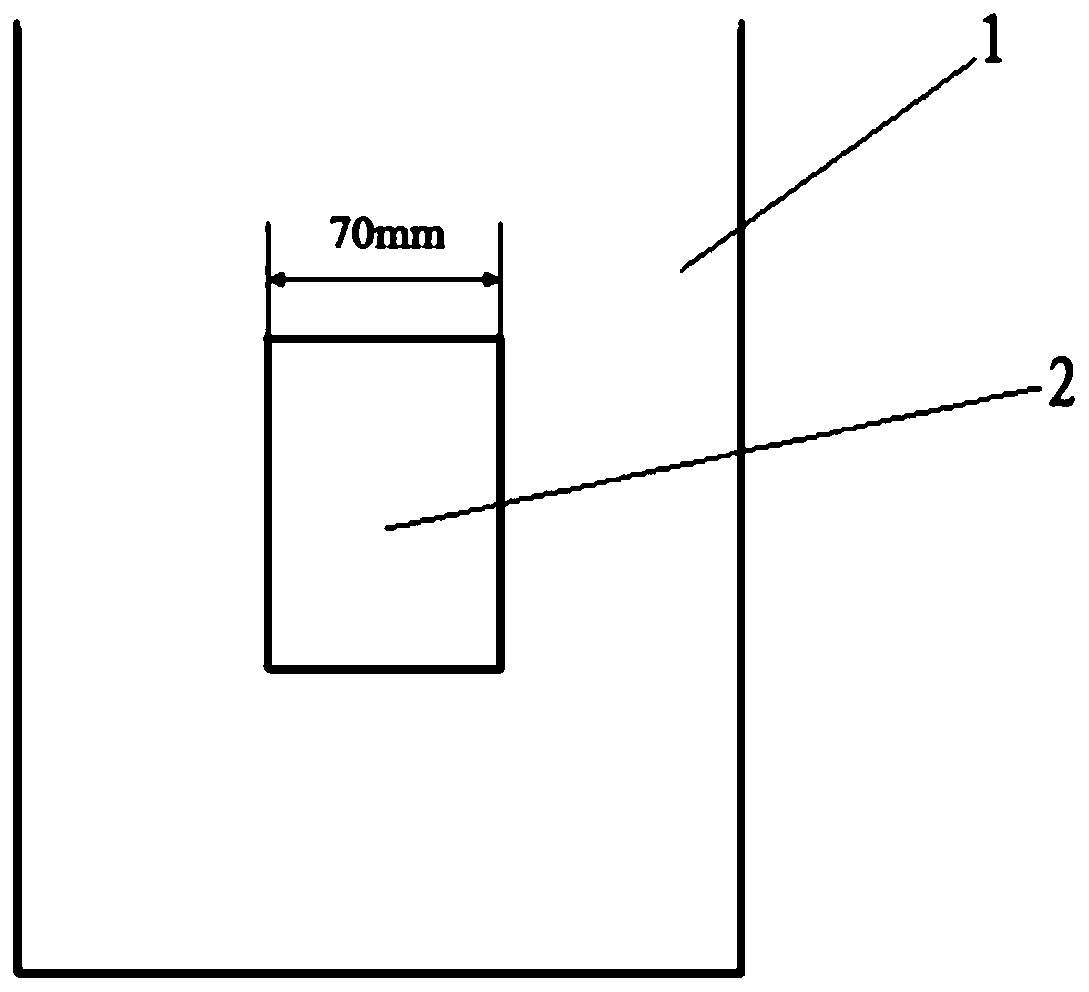

[0019] There are nozzle outlets on both sides of the lower part of the nozzle body, and the upper and lower edges of the nozzle outlet are smoothly transitioned. The upper and lower sides of the taphole are in a smooth transition shape along the inner wall, which can reduce the eddy current generated here d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com