Milling machine for machining graphite insulation barrels

A heat preservation barrel and milling machine technology, which is applied in the field of milling machines, can solve the problems of high price, increased production cost, and small stroke of vertical CNC lathe, and achieve the effect of reducing production cost and low machine tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

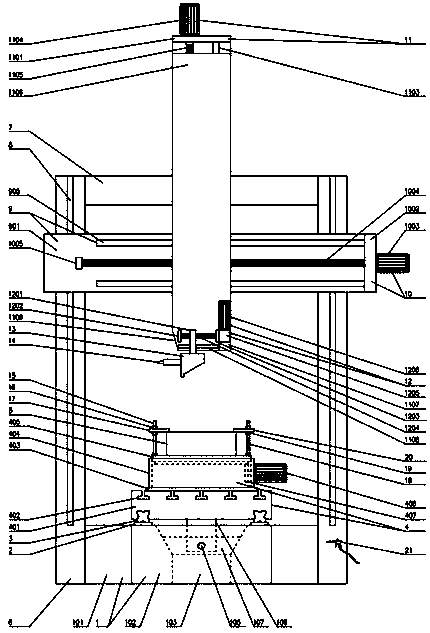

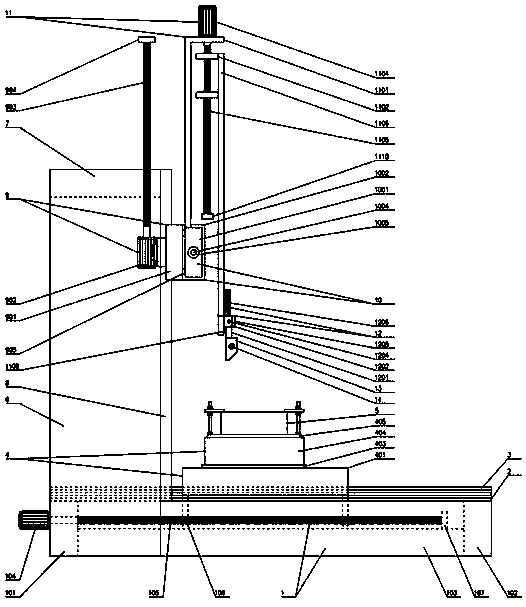

[0020] refer to Figure 1-2 , a milling machine for processing graphite heat preservation barrels described in this specific embodiment, including a platform assembly 1, a backing plate A2, a guide rail A3, a sliding assembly A4, a graphite column 5, a support arm 6, a connecting plate B7, a guide rail B8, and a lifting assembly A9, sliding assembly B10, lifting assembly B11, sliding assembly C12 and cutter A13, the left and right sides of the platform assembly 1 are respectively fixedly provided with backing plates A2, and the platform assembly 1 includes a fixed platform A101, a fixed platform B102, and a Y-shaped groove 103 , motor A104, threaded rod A105, connecting plate A106, the fixed platform B102 is fixedly arranged in the middle of the front side wall of the fixed platform A101, the same Y-shaped groove 103 is opened on the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com