Sprayer head cleaning device and printing machine

A technology for cleaning devices and nozzles, applied in printing and other directions, can solve the problems of inability to clean online at any time, unsuitable for continuous printing production requirements, and affecting printing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

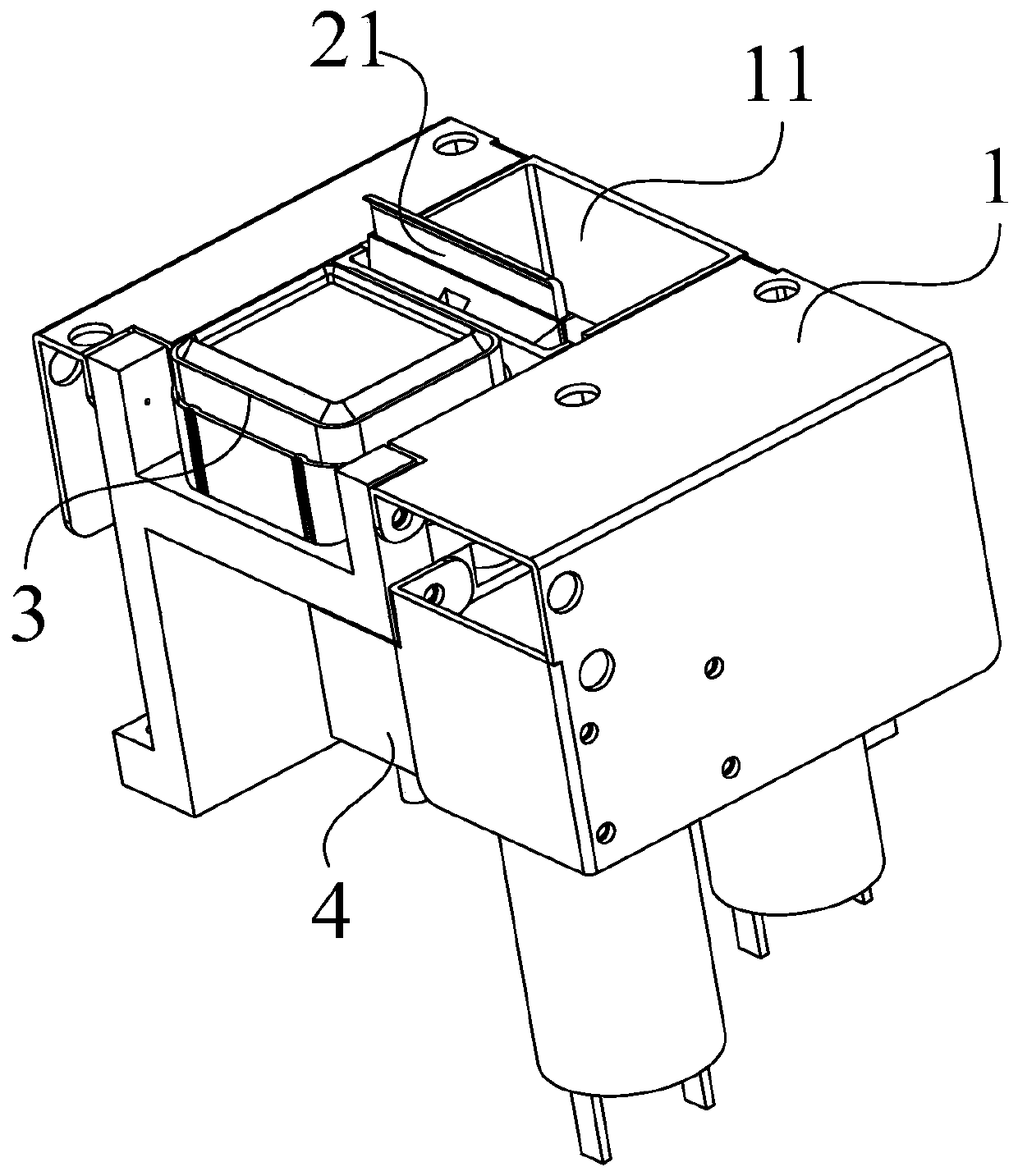

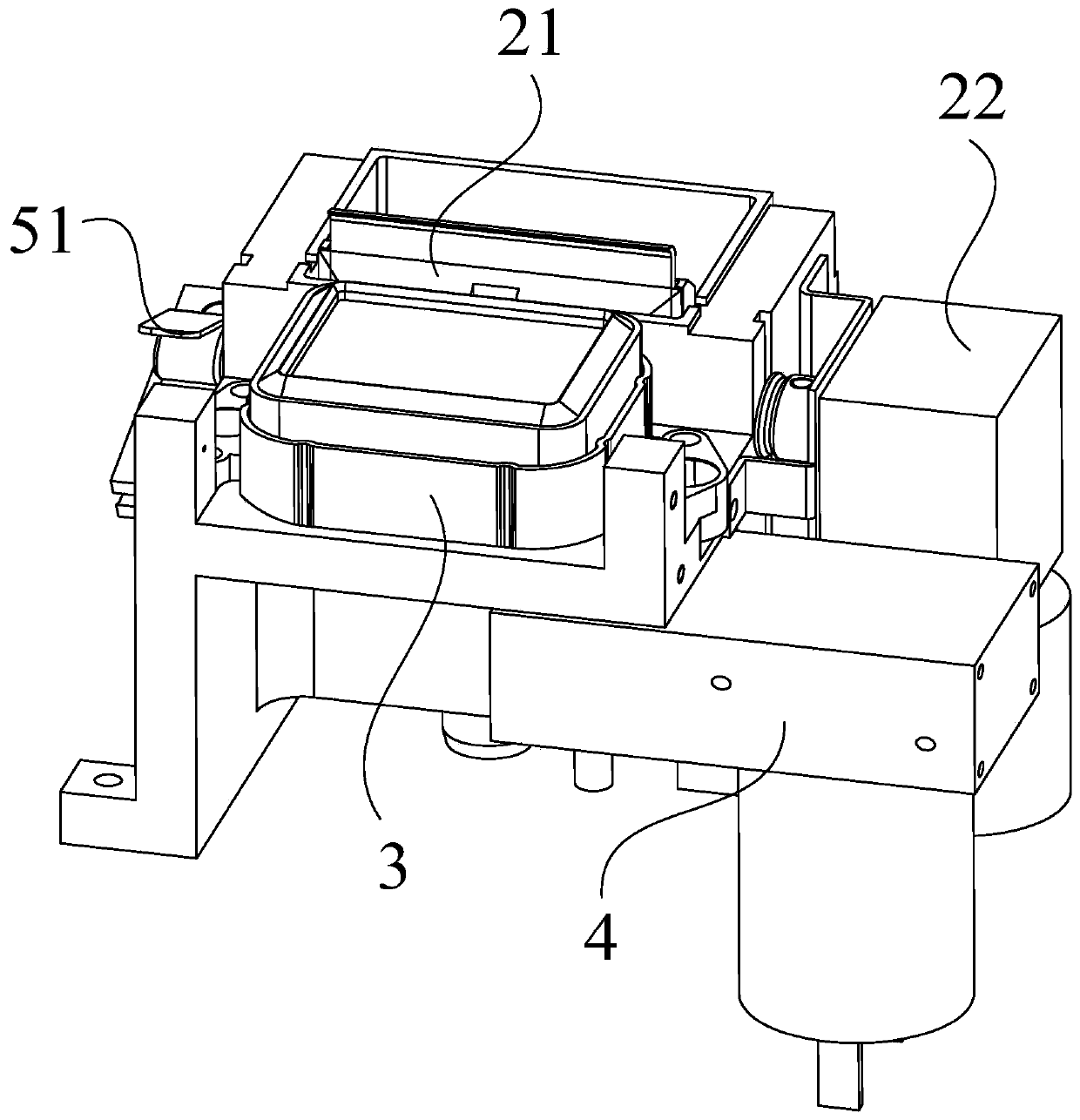

[0035] Such as Figure 1 ~ Figure 4 As shown, the embodiment of the present application provides a nozzle cleaning device, including: a housing 1, and an ink scraping assembly 2, an ink stack 3, an ink pump 4 and a detection assembly arranged in the housing 1; the ink scraping assembly 2, The ink stack 3, the ink pump 4 and the detection components are all integrated and fixed in the casing 1. Due to the compact structure of the casing 1 and the reasonable layout, the integrated design saves the installation space of the nozzle cleaning device; The isolation of the ink stack 3 and the ink pump 4 not only protects electrical components from waste ink pollution, but also controls waste ink pollution within a certain range; among them, the shell 1 is made of polypropylene, which not only reduces the weight of the shell 1, It also reduces the weight of the entire nozzle cleaning device.

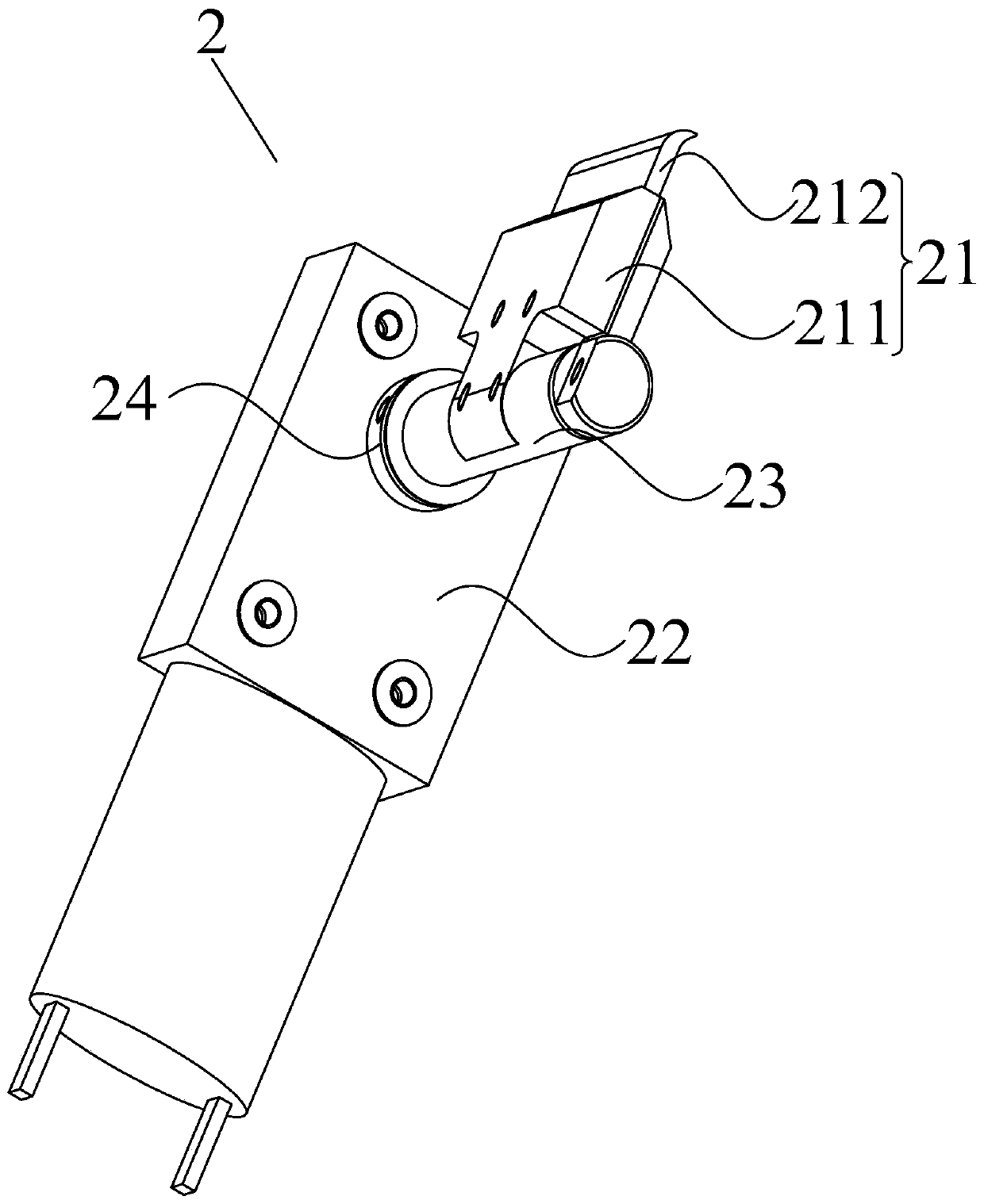

[0036] Such as image 3 As shown, the scraper assembly 2 includes a scraper 21, a power mec...

Embodiment 2

[0058] Based on the same technical idea, the present application also provides a printer, including the nozzle cleaning device in Embodiment 1; wherein, the scraper of the nozzle cleaning device is set close to the nozzle of the printer, and in the initial state, the nozzle of the scraper and the nozzle is located plane vertical.

[0059] When the nozzle cleaning device is working, the scraper is perpendicular to the plane where the nozzle of the nozzle is located, so that the ink scraping is more thorough and clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com