Method for finding holes visually and forklift

A vision and forklift technology, applied in the field of visual hole finding, methods and forklifts, can solve the problem that the fork tines cannot enter the fork holes accurately, and achieve the effects of strong anti-interference ability, large amount of information, and accurate positioning and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

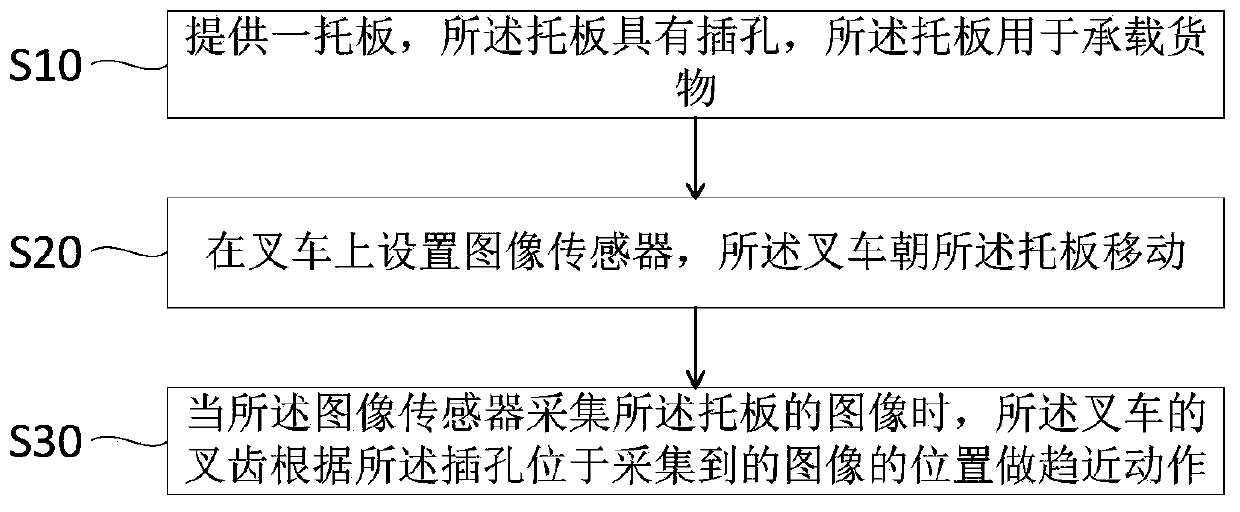

[0019] Such as figure 1 As shown, the present invention provides a method for visually finding holes, including:

[0020] S10. Provide a pallet, the pallet has jacks, the jacks can usually be two symmetrically arranged cavities, the pallet is used to carry goods, and the pallet serves as a loading platform;

[0021] S20. An image sensor is set on the forklift, and the forklift moves toward the pallet, that is, moves to the side of the pallet in the direction of the goods;

[0022] S30. When the image sensor captures the image of the pallet, the fork of the forklift performs an approaching action according to the position of the jack in the captured image, and the fork works in cooperation with the jack. The tines go deep into the socket for subsequent lifts.

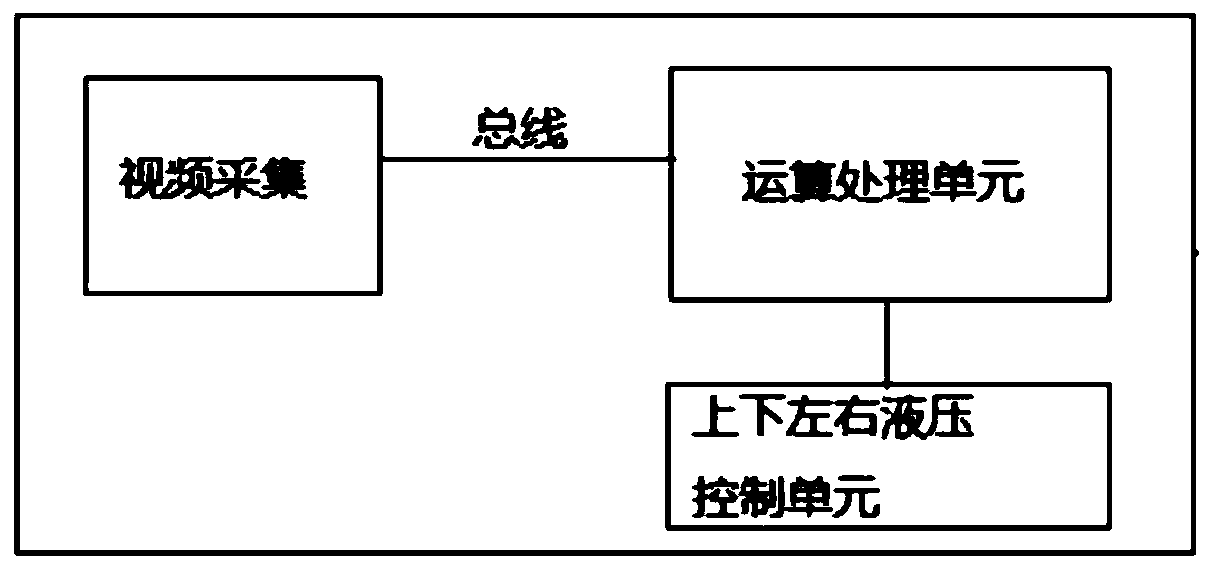

[0023] The invention finds the position of the socket of the pallet through the image sensor, and tracks the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com