Sinusoidal force system friction testing method

A technology of system friction force and test method, applied in the field of control, can solve the problems of inaccurate test, modeling error, poor constant speed accuracy, etc., and achieve the effect of large amount of data information, high efficiency, and short test process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

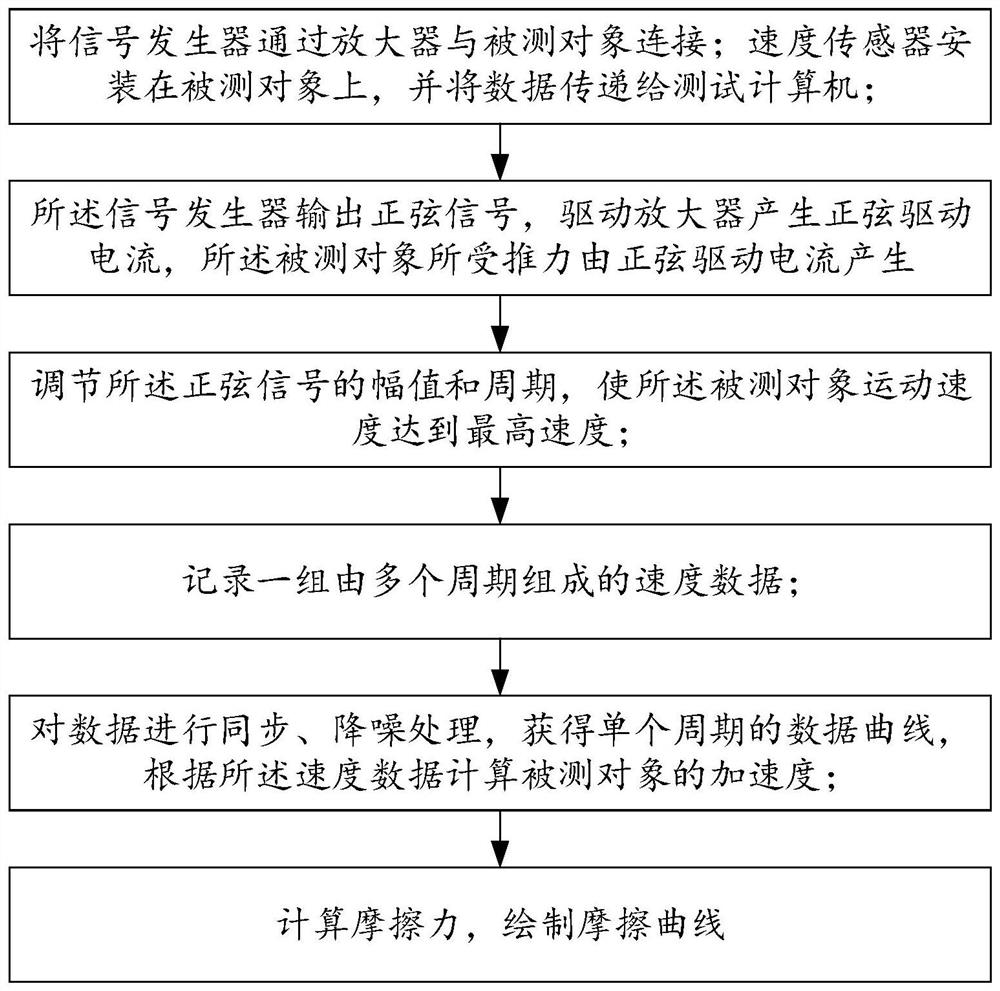

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: For testing linear motors

[0037] Step 1: Prepare the drive amplifier and set it in current mode; use the ARS2000 driver and set it to current drive mode through software.

[0038] Step 2: Connect the data generator, data collector, drive amplifier, and the system under test. Use PC and dSPACE DS1104 board to form data output and input system, use MATLAB software to design sinusoidal drive signal, input and output channel accessories system. Connect the analog output of DS1104 to the driver, connect the driver to the BOB-DTL85 linear motor, and connect the motor sensor to the DS1104 pulse interface.

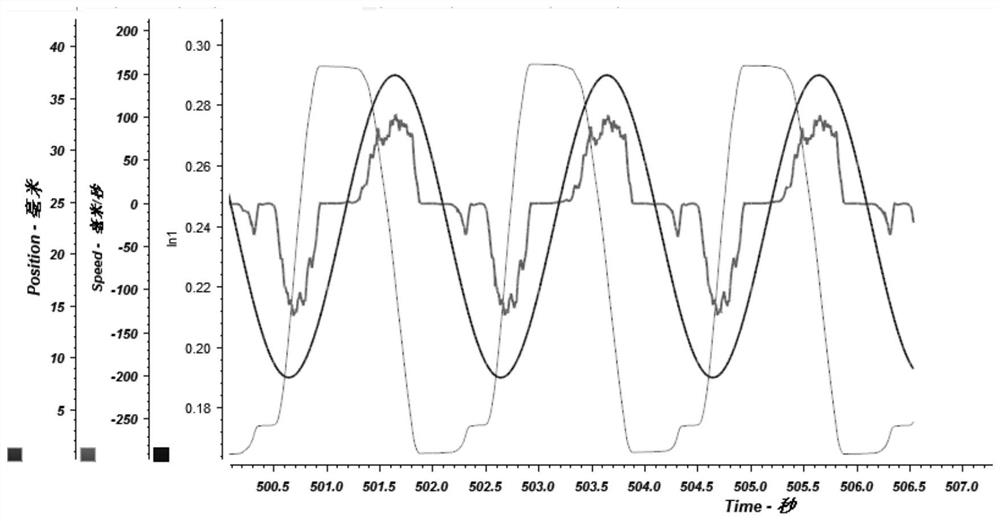

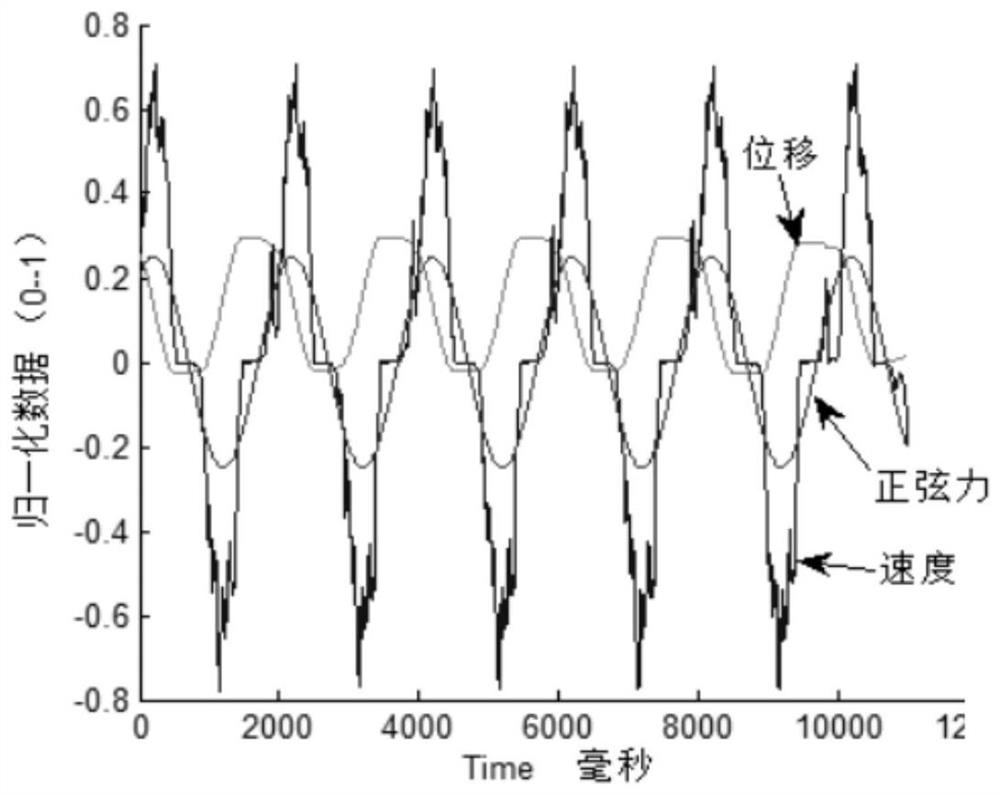

[0039] Step 3: output sinusoidal signal, drive amplifier to generate sinusoidal drive current, motor thrust F=ρAsin(ωt), ρ is thrust-current coefficient, fixed constant. Make the motor do reciprocating motion under the drive of sinusoidal force. Use Controdesk test software software to adjust the amplitude A and frequency ω of the signal. Generally, the ...

Embodiment 2

[0046] Embodiment 2: for rotating electric machine

[0047] The first step: same as embodiment one

[0048] Step 2: Connect the data generator, data collector, drive amplifier, and the system under test. Use PC and dSPACE DS1104 board to form data output and input system, use MATLAB software to design sinusoidal drive signal, input and output channel accessories system. Connect the analog output of DS1104 to the driver, connect the driver to the Kollmorgen AKM42G three-phase rotating motor, and connect the motor sensor to the DS1104 pulse interface.

[0049] The third step to the eighth step: with embodiment one;

Embodiment 3

[0050] Embodiment three: used for testing the torque motor.

[0051] The first step: same as embodiment one

[0052] Step 2: Connect the data generator, data collector, drive amplifier, and the system under test. Use PC and dSPACE DS1104 board to form data output and input system, use MATLAB software to design sinusoidal drive signal, input and output channel accessories system. Connect the analog output of DS1104 to the driver, connect the driver to the Yaskawa SGMCS-08D direct drive motor, and connect the motor sensor to the DS1104 pulse interface.

[0053] The third step to the eighth step: the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com