A Fractional Order Control Method for the Rotational Speed of the Cutter Drive System of Roadheader

A cutterhead drive and disk drive technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the problems of anti-interference ability and control effect that cannot meet the actual construction, and achieve high design freedom and good closed loop performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below with reference to specific embodiments and accompanying drawings.

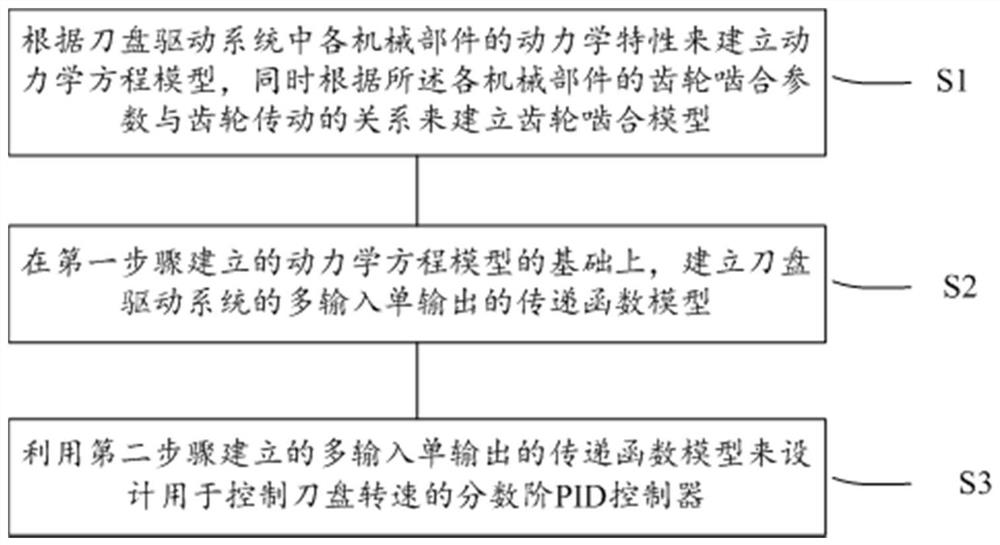

[0026]figure 1 Schematically shows a flow chart of a method for fractional-step control of the rotational speed of the cutter head drive system of a roadheader according to a preferred embodiment of the present invention.

[0027]Such asfigure 1 As shown, the method for controlling the rotational speed of the cutter head drive system of a roadheader according to a preferred embodiment of the present invention includes:

[0028]The first step S1: Establish a dynamic equation model according to the dynamic characteristics of each mechanical component in the cutter head drive system, and establish a gear mesh model according to the relationship between the gear meshing parameters of each mechanical component and the gear transmission.

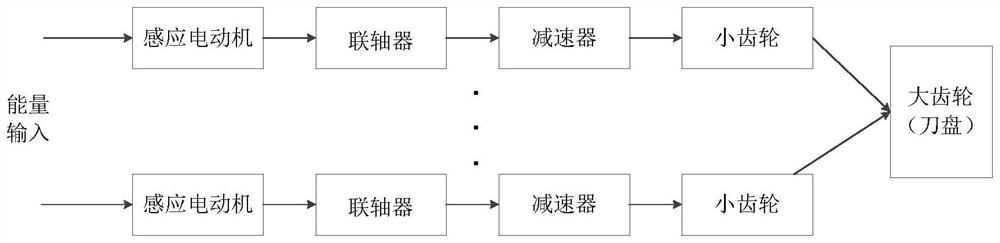

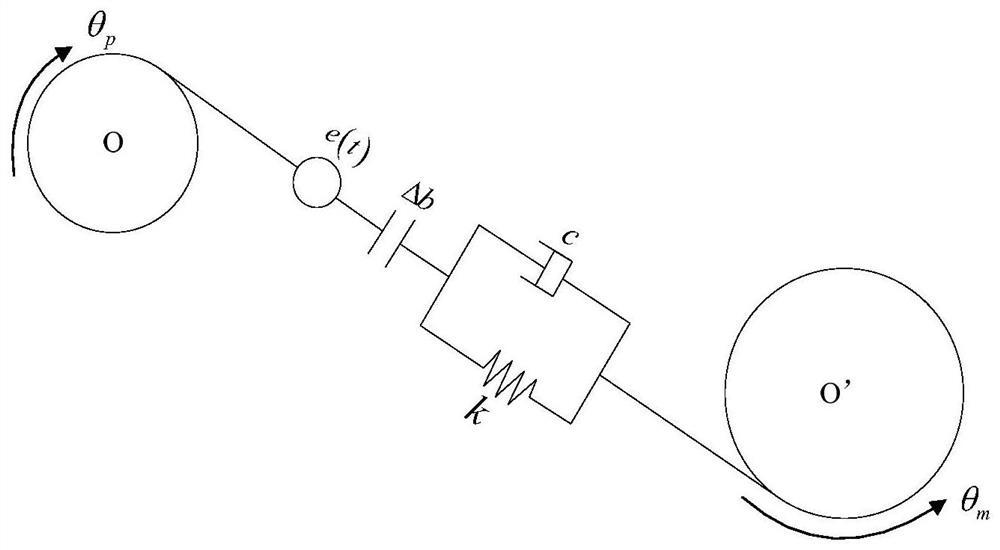

[0029]That is, the dynamic chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com