Environment-friendly flexible fireproof cable

A fire-proof cable and environmentally friendly technology, applied in the direction of lifting device, multi-axis trolley, trolley accessories, etc., can solve the problems that the cable is not easy to move, and the reel of the cable cannot be erected at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

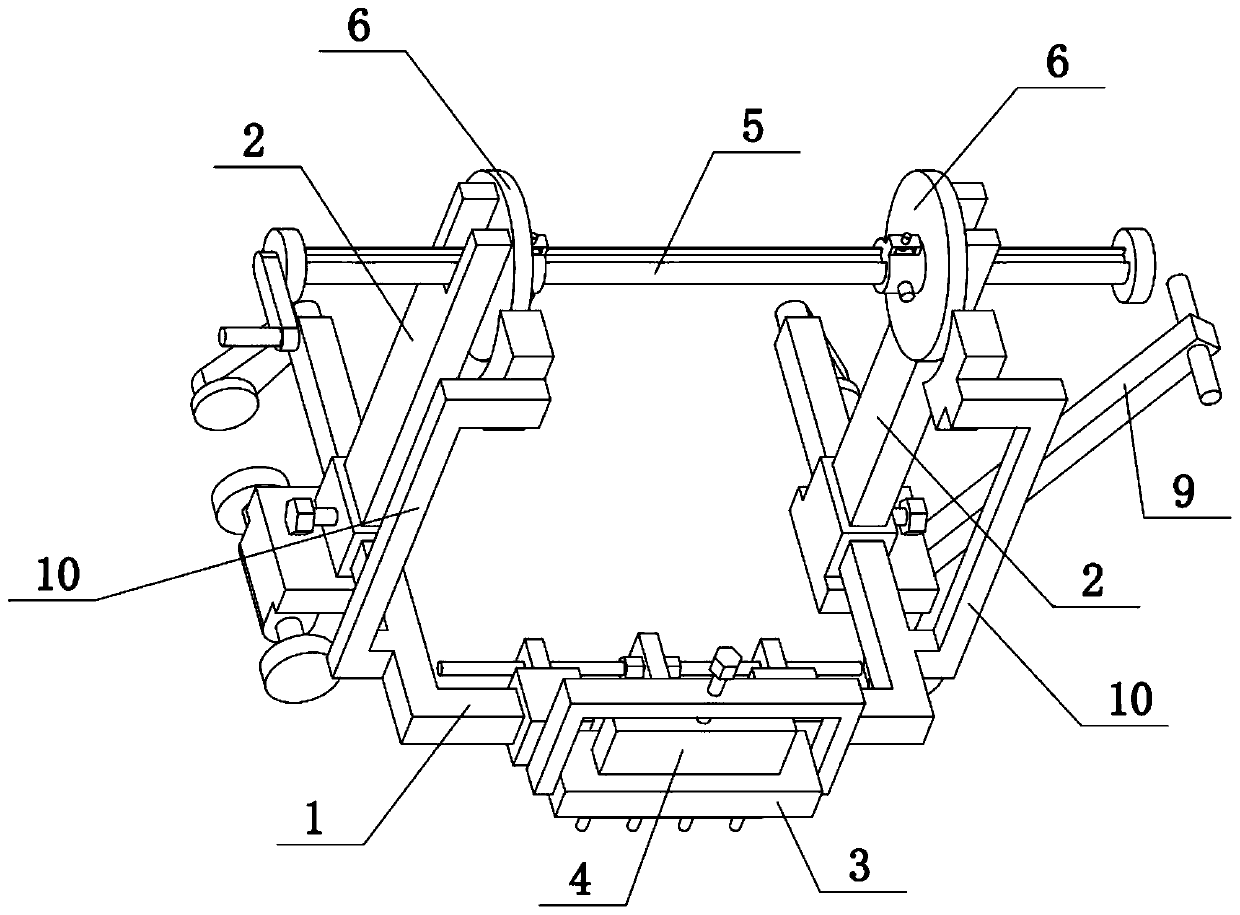

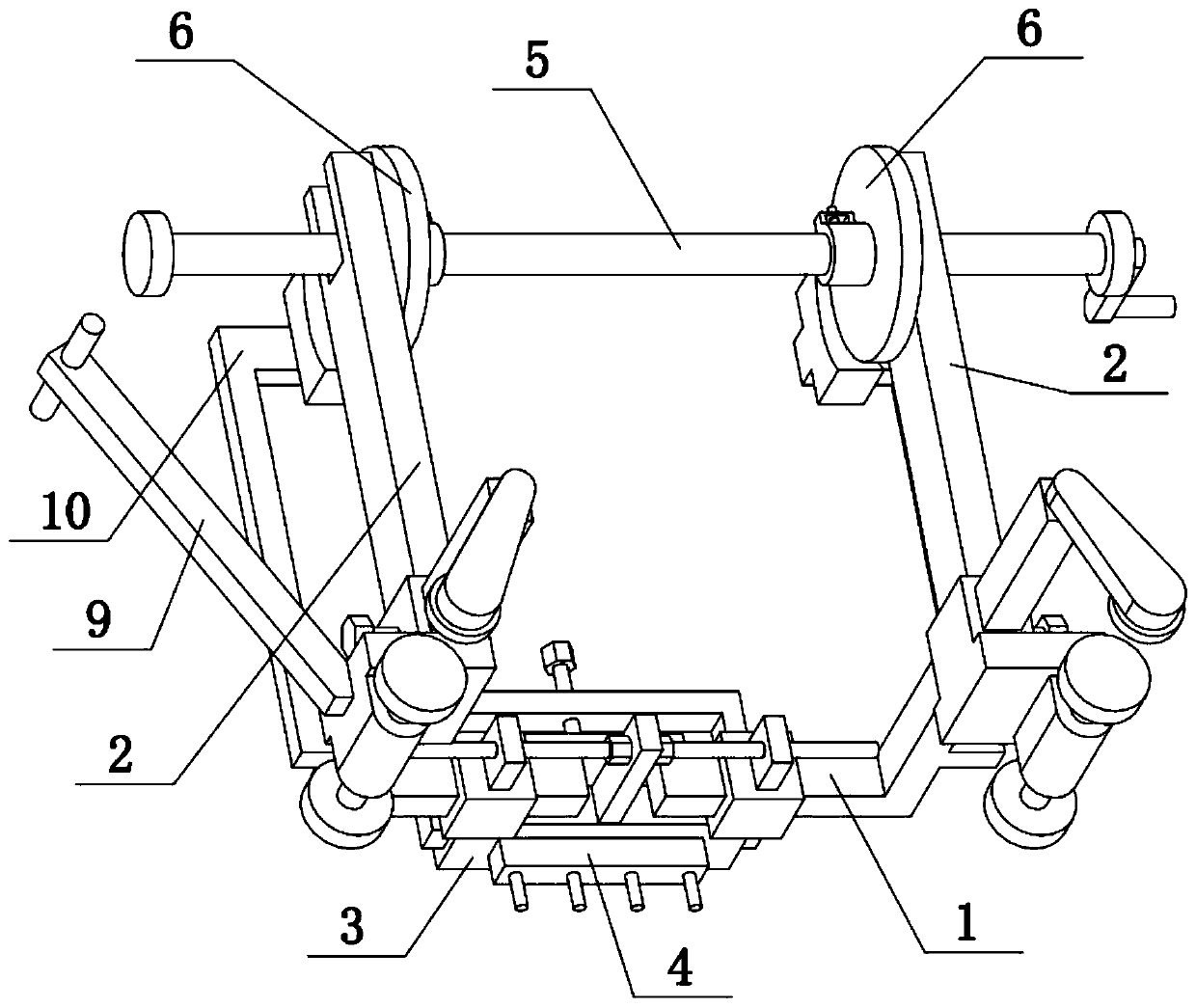

[0034] Combine below Figure 1-12 To illustrate this embodiment, the present invention relates to a cable, more specifically an environment-friendly flexible fireproof cable, which includes a bottom frame 1, a vertical frame 2, a middle connecting frame 3, a ground insert 4, a cable roll shaft 5, and a cable Limiter 6, cable 7, fireproof layer 8, handle 9 and fixer 10, the distance between two cable limiters 6 in the present invention can be adjusted, which is convenient for adjusting the two cable limiters according to the different specifications of cables 7 6; when the cable 7 needs to be moved, the cable shaft 5 and the two cable stoppers 6 can be fixed, and the runner 2-2 can be used to facilitate the movement of the cable 7; when the cable 7 needs to be used, the runner 2-2 can be moved. 2 lock, unfix the roll cable shaft 5 and the two cable stoppers 6, and erect the roll cable shaft 5 firmly.

[0035]There are two vertical frames 2 on the left and right, and the two ve...

specific Embodiment approach 2

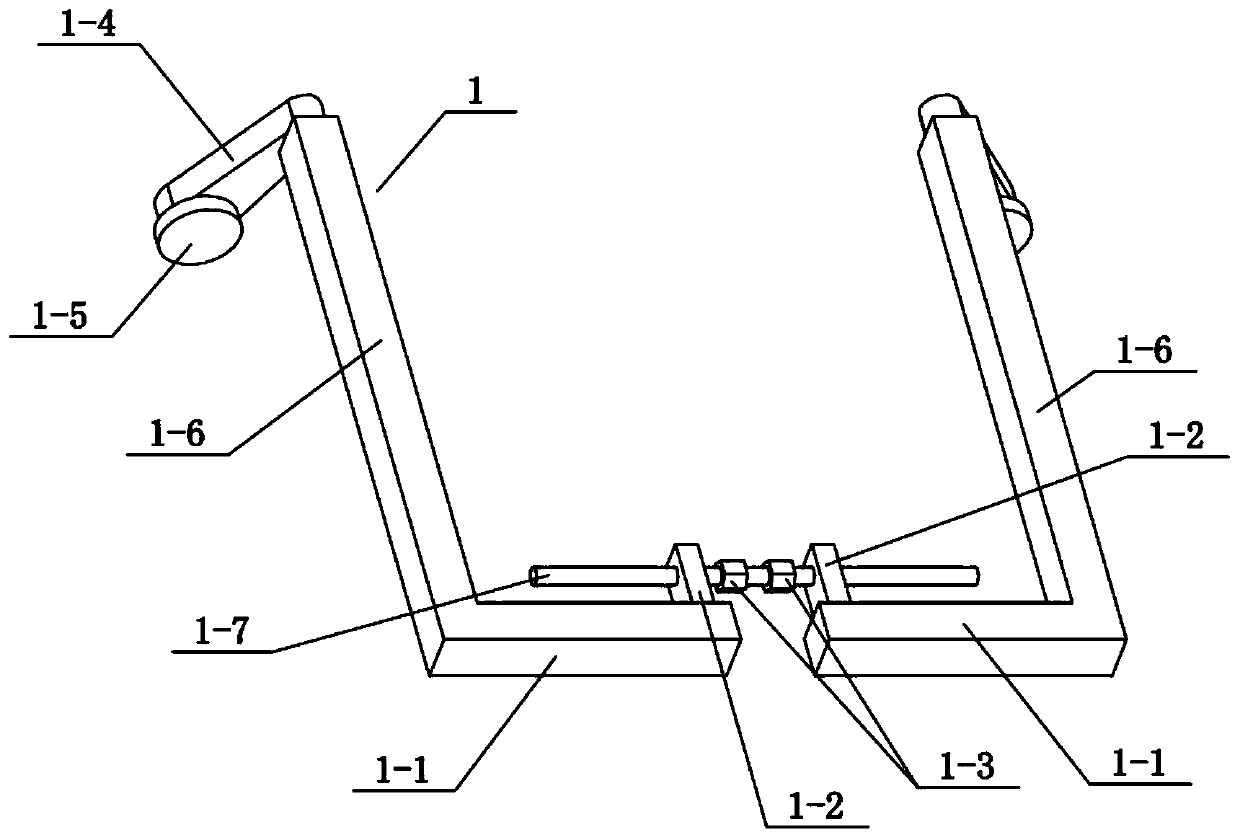

[0037] Combine below Figure 1-12 To illustrate this embodiment, the chassis 1 includes a square pole I1-1, a protruding piece 1-2, a hexagonal head 1-3, a pressing piece 1-4, a square pole II1-6 and a double-threaded screw 1-7 , there are two square pillars II1-6 left and right, the front ends of the two square pillars II1-6 are fixedly connected with square pillars I1-1, and the inner ends of the two square pillars I1-1 are fixedly connected with convex Sheet 1-2, the helical directions of the left and right ends of the double-threaded screw 1-7 are opposite, and the left and right ends of the double-threaded screw 1-7 cooperate with the two protruding pieces 1-2 through threads respectively, and the double-threaded screw 1-7 There are two hexagonal swivels 1-3 at the middle position, the two hexagonal swivels 1-3 are located between the two lugs 1-2, and the rear ends of the two square poles II1-6 are fixedly connected with pressing pieces 1-4. Rotating one of the hexagon...

specific Embodiment approach 3

[0039] Combine below Figure 1-12 To illustrate this embodiment, the vertical frame 2 includes a base plate 2-1, a runner 2-2, a wheel seat 2-3, a fastening screw 12-4, a fixing sleeve 12-5, a vertical bracket 2-6 and a rotating groove Mouth 2-7, the lower end of base plate 2-1 is fixedly connected with wheel seat 2-3, and the front and rear ends of wheel seat 2-3 are all rotatably connected with runner 2-2, and the upper end of base plate 2-1 is fixedly connected with The fixed sleeve I2-5, the fixed sleeve I2-5 is threadedly connected with the fastening screw I2-4, the upper end of the fixed sleeve I2-5 is fixedly connected with the vertical support 2-6, and the upper end of the vertical support 2-6 is provided with a rotation groove Port 2-7; the two vertical frames 2 are respectively slidably connected to the two square poles II1-6 through the fixing sleeves I2-5 on them, and the two fastening screws I2-4 are respectively supported on the two square poles II1 -6 on. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com