A bayonet type automatic reset machine-hydraulic linkage door lock device and operation method in a car

An automatic reset and bayonet technology, used in vehicle locks, hydraulic/pneumatic locks, power control mechanisms, etc., can solve the problem of vehicle sealing, reduced safety, occupant safety threats, and increased clearance between the tailgate and the vehicle body, etc. problems, to achieve the effect of simple installation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

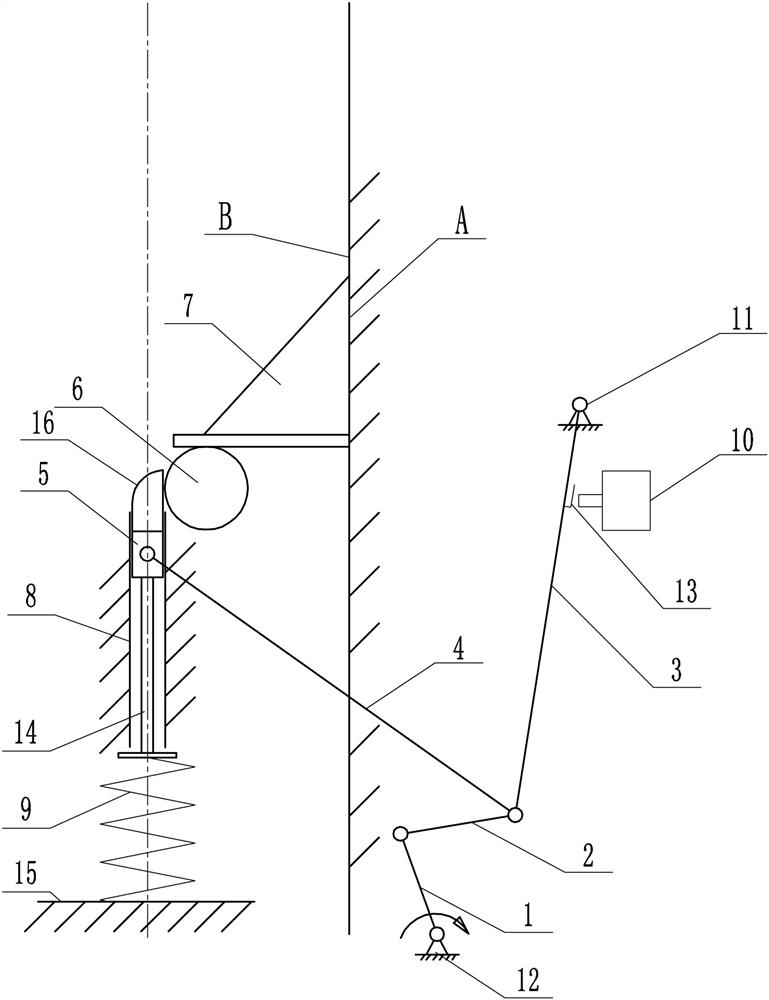

[0026] Such as figure 1 , a bayonet type automatic reset mechanical-hydraulic linkage door lock device in a car, which includes a handle hinge seat 12, a handle 1 is hinged on the handle hinge seat 12, and the other end of the handle 1 passes through a handle adapter plate 2 At the same time, a swivel frame 3 and a connecting rod 4 are hinged, and the other end of the swivel frame 3 is hinged on the hinged seat 11 of the swivel frame, and the swivel frame 3 is matched with a hydraulic valve group 10 for controlling the hydraulic jack of the tailgate; The other end of the connecting rod 4 is hinged to a latch assembly for locking the vehicle door; the latch assembly cooperates with the door pin 6 arranged on the tailgate, and locks the vehicle door. The mechanical-hydraulic linkage door lock device can always maintain stability under complex conditions, and has the advantages of better reliability, simple structure, and convenient installation compared with existing door lock m...

Embodiment 2

[0034] The operation method of the mechanical-hydraulic linkage door lock device with bayonet type automatic reset in any one of the vehicles is characterized in that:

[0035] Closing process:

[0036] When the hydraulic ejector works to pull up the door, the bayonet bolt 5 is pressed down by the door pin 6, and when the door pin 6 reaches the predetermined position, the bayonet pressure spring 9 returns to its original state and lifts the bayonet bolt 5 to block the door pin 6, so as to realize the locking of the car door;

[0037] Door opening process:

[0038] When the door needs to be opened, press down the handle 1, and the handle 1 will synchronously drive the rotary frame 3 and the connecting rod 4 through the handle adapter plate 2, and the contact point 13 on the rotary frame 3 will be in contact with the hydraulic valve group 10, thereby triggering the hydraulic valve group 10 , the hydraulic valve group 10 will control the hydraulic ejector rod to work, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com