Oil filtering and noise reducing structure of range hood

A range hood and oil filtering technology, which is applied in the field of kitchen appliances, can solve the problems of unfavorable oil net cleaning, reduce the air intake area, and small condensation area, so as to improve the oil separation performance, improve the purification efficiency, and improve the noise reduction performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

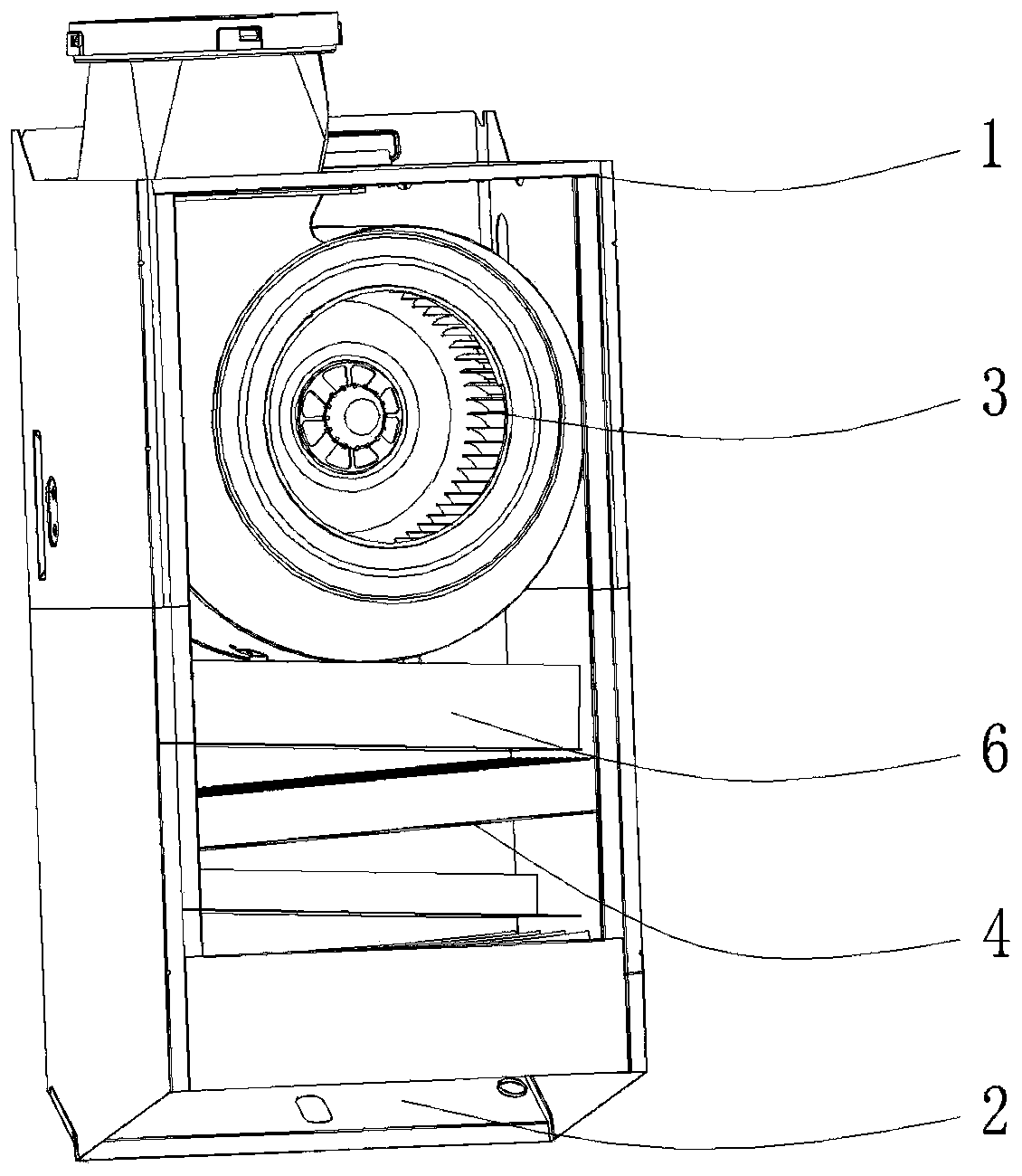

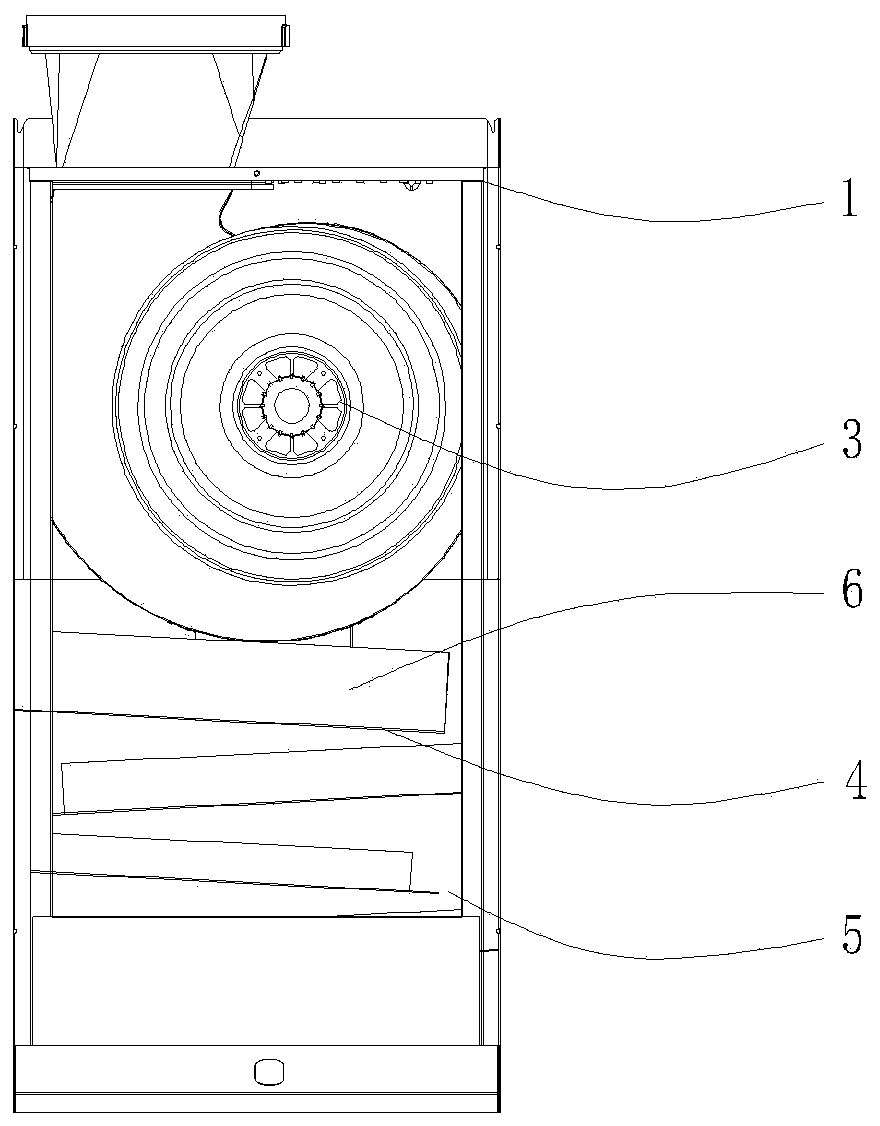

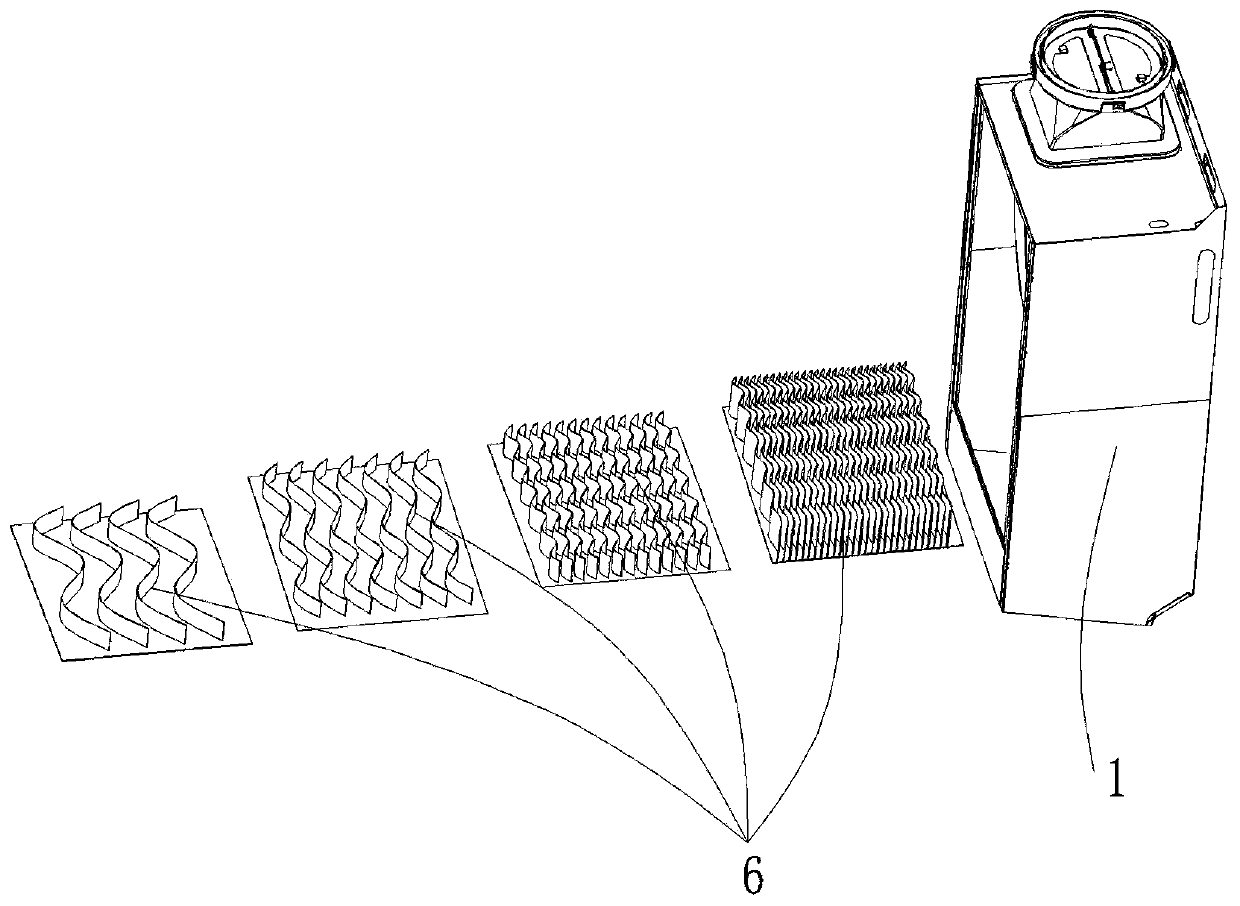

[0026] Such as Figures 1 to 4 As shown, this embodiment provides an oil filter and noise reduction structure for a range hood. The range hood includes a hood main body 1 with an air inlet, and an oil net 2 is arranged at the air inlet of the hood main body 1. The main body 1 is provided with a fan 3, and a plurality of partitions 4 are arranged at intervals between the oil screen 2 and the fan 3, and a vent 5 is formed between the partition 4 and the side wall of the main body 2 of the hood, and the partitions 4 are set at a slant.

[0027] In this embodiment, the range hood includes a hood main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com