A Method for Eliminating the Blind Area of the Slab Entering the Furnace

A heating furnace and slab technology, which is applied in the field of eliminating the blind area of the slab entering the furnace, can solve the problems of increasing the time of the slab in the furnace, increasing the gas consumption, and wasting energy, so as to improve production efficiency, reduce energy consumption, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

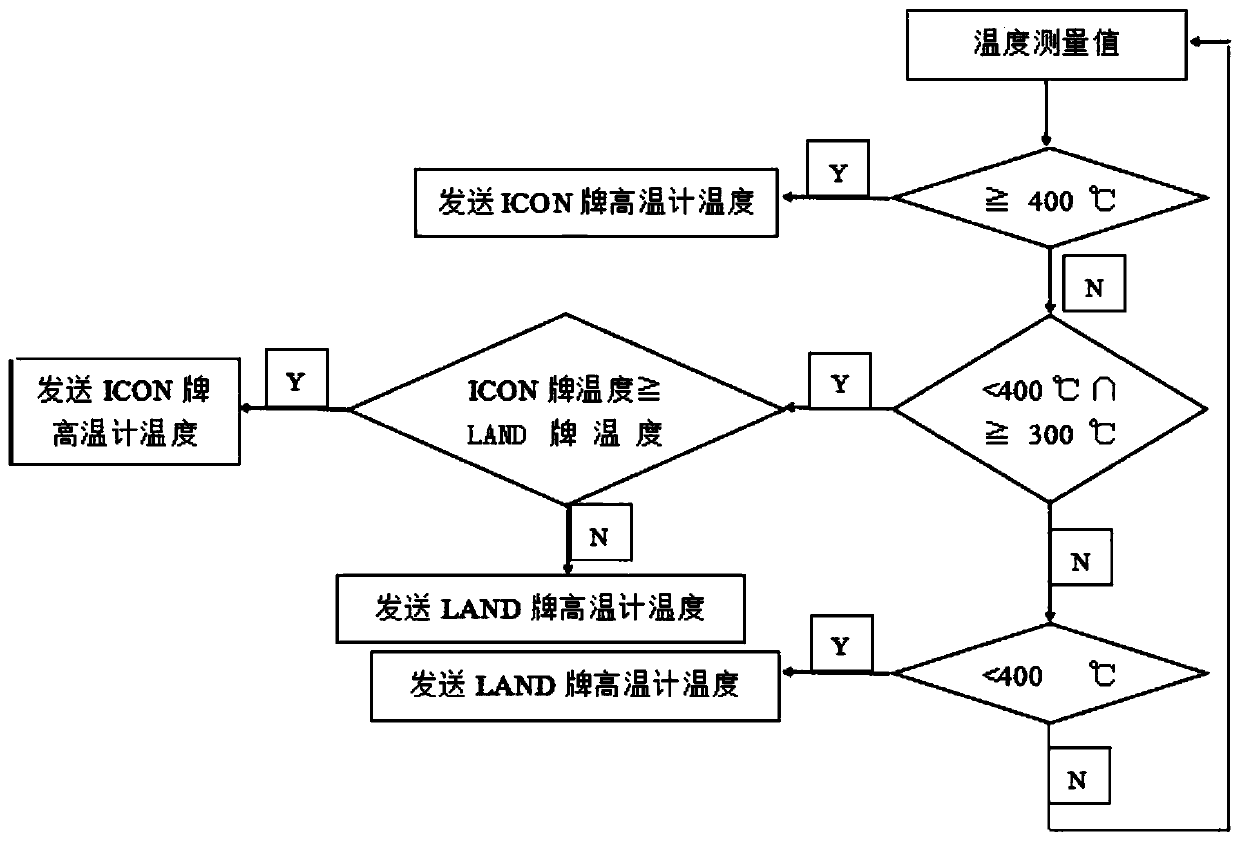

[0023] This embodiment provides a method for eliminating the blind area of the slab entering the furnace, comprising:

[0024] S1. On the basis of the existing large-range pyrometer, install a small-range pyrometer around the slab check. The temperature range of the large-range pyrometer is 300-1300°C, and the temperature range of the small-range pyrometer is 0~ 400°C; large-range pyrometers use ICON pyrometers, and small-range pyrometers use LAND pyrometers. During the installation of pyrometers, accurate position simulation is performed to ensure that the projection point of the pyrometer is in the middle of the target;

[0025] S2. Connect the signals of the large-range pyrometer and the small-range pyrometer to the PLC system. After comparing the readings of the two pyrometers, the PLC system selects the appropriate pyrometer for data processing, calculation and sending to the secondary system of the heating furnace. ;The PLC system adopts the signal isolation module to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com