Garment sewing assembly line optimization method

An optimization method and pipeline technology, applied in the direction of manufacturing computing systems, instruments, computing models, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

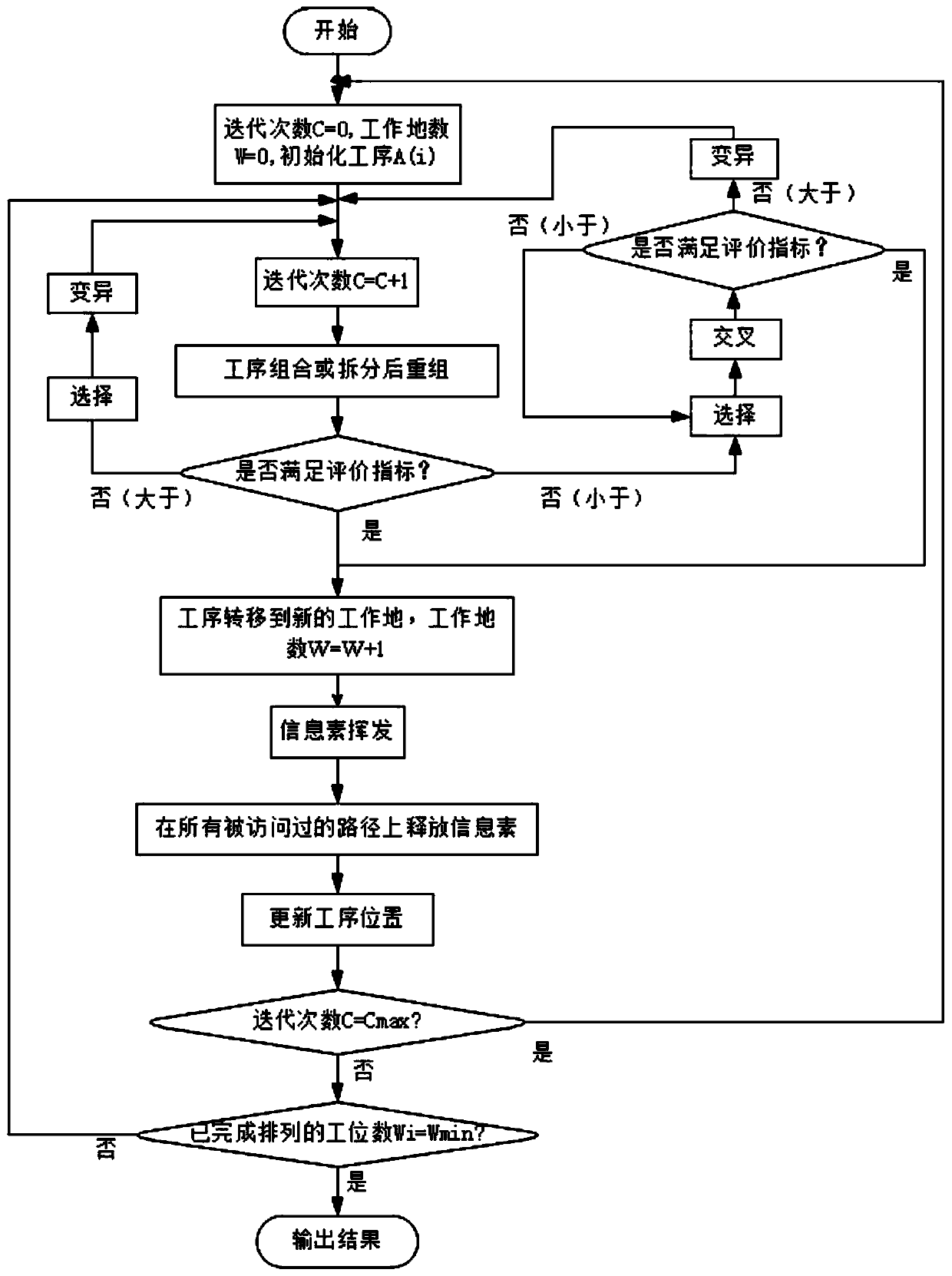

[0035] see figure 1 , is a garment sewing line optimization method provided by the embodiment of the present invention, such as figure 1 As shown, the method includes step 1: process initialization, determine the initial position of each process; set the population size A(i), crossover probability J, mutation probability B, iteration number C; ant colony initialization, randomly generate ant colony Initial position; wherein, the initial parameters of the ant colony include an ant colony scale, and the ant colony scale is greater than the total number of processes.

[0036] Step 2: start to iterate and record the number of iterations; the iteration is a cycle of selecting a process for the currently visited station according to preset conditions; specifically, according to the module division of the task map and the weight of the process in each module, calculate The probability of process transfer and select the process with high probability for the currently visited station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com