Wire harness connector assembly device

A wire harness connector and assembly device technology, which is applied in the assembly/disassembly of contacts, etc., can solve problems such as insufficient fixing of connector pins, and achieve the effects of compact structure, low cost, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

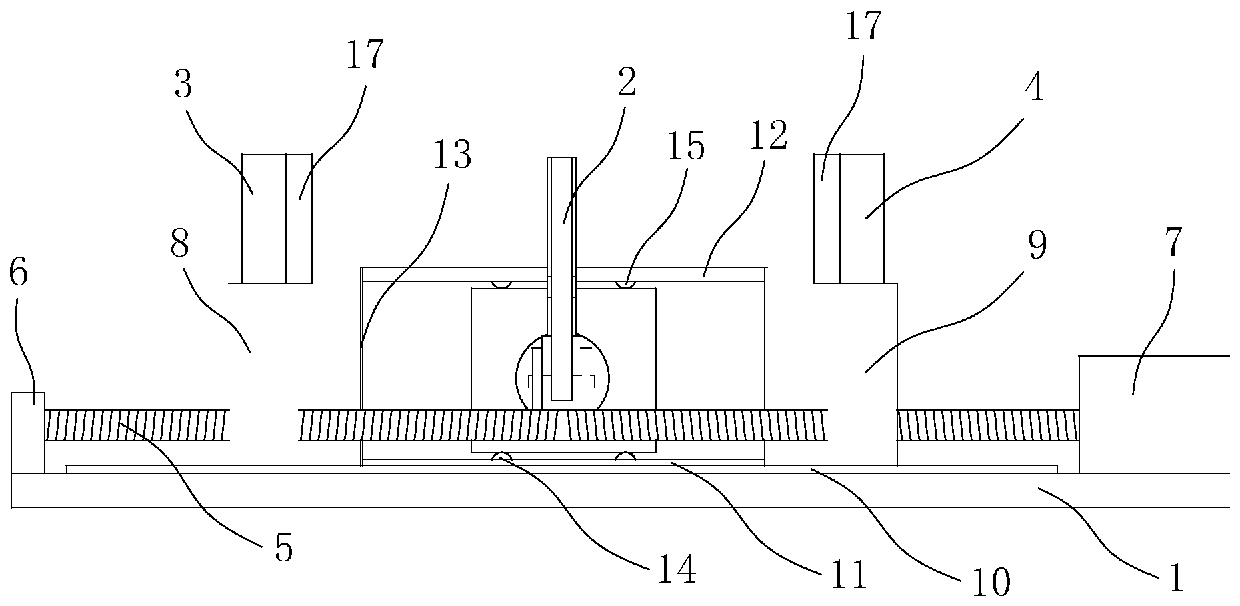

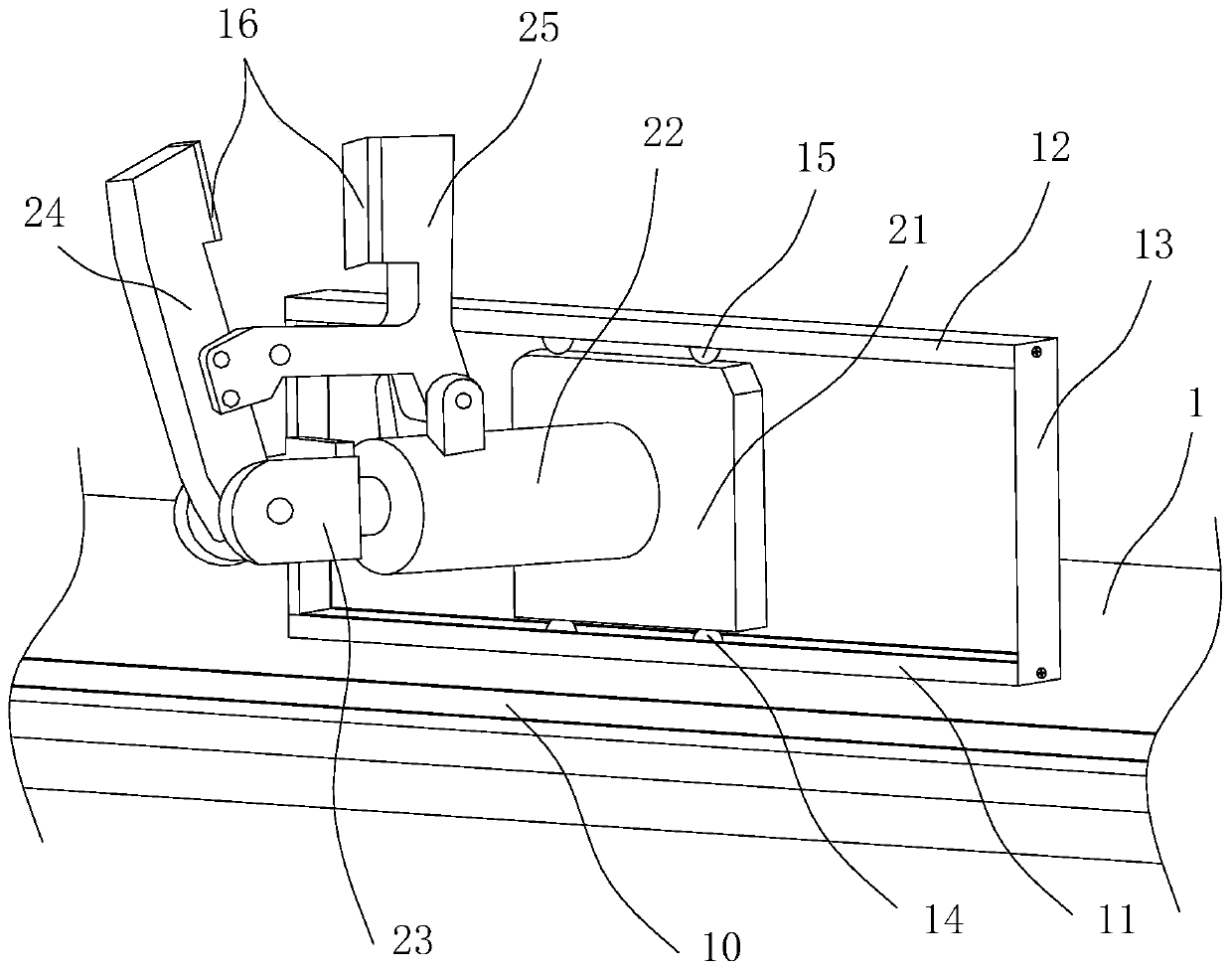

[0032] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0033] In this example, if figure 1 As shown, a wire harness connector assembly device includes a base 1, and a pre-clamping mechanism 2 is provided on the upper surface of the base 1, which is suitable for clamping the connector. A synchronous movement mechanism is provided on the base 1 , and the synchronous movement mechanism includes a first clamping block 3 and a second clamping block 4 . The first clamping block 3 and the second clamping block 4 are arranged oppositely, and the first clamping block 3 and the second clamping block 4 form a clamping opening. The first clamping block 3 and the second clamping block 4 move synchronously to the pre-clamping mechanism 2 to tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com