Drive unit and method for controlling drive unit

A drive unit and drive motor technology, which is applied in the direction of motor control, control system, and mechanical energy control, etc., can solve the problems of large influence of tolerance, change of adjustment speed, and complicated application of drive unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

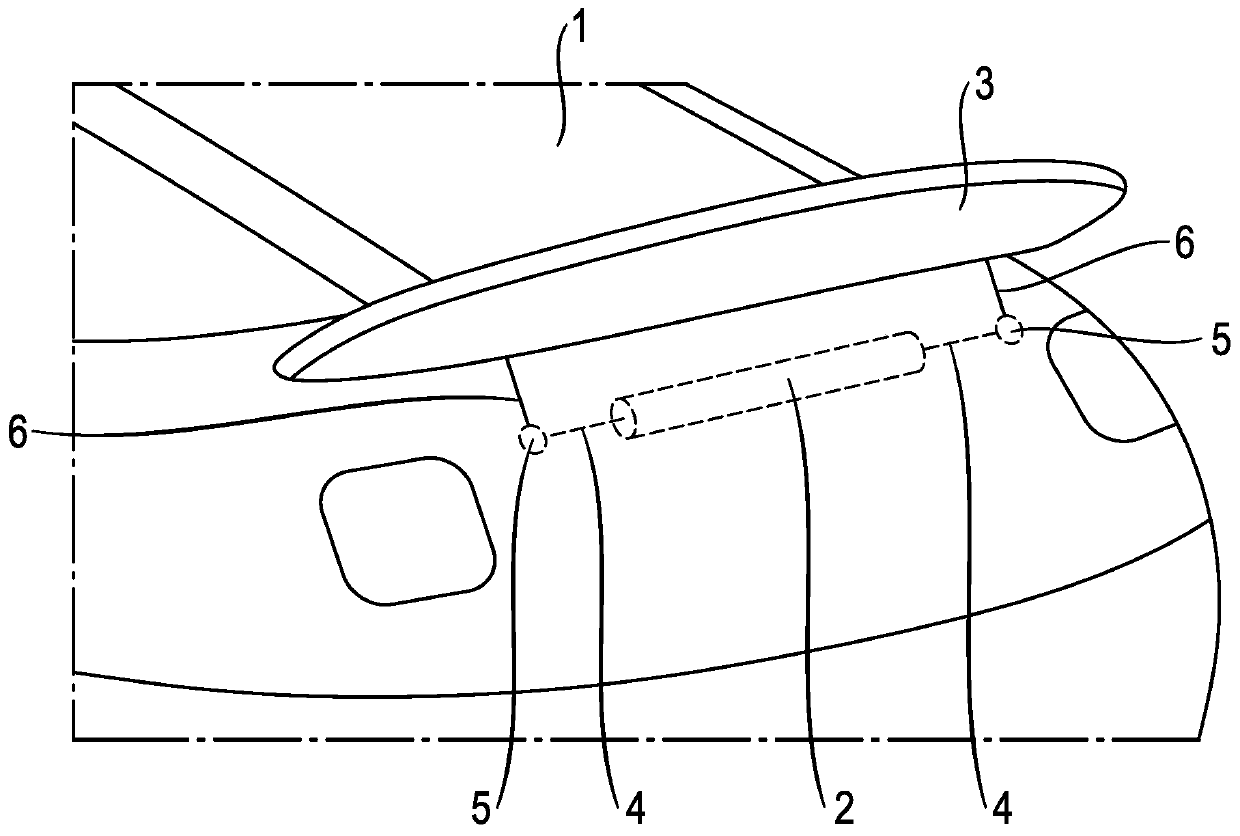

[0034] figure 1 Shown is a partial perspective view of a motor vehicle 1 with a drive unit 2 according to the invention for adjusting or actuating an air guiding element 3 , such as a rear spoiler. The air guide element here can also be other air guide elements, such as a front spoiler or the like.

[0035] The drive unit 2 for adjusting the air guide element 3 of the motor vehicle 1 has a drive motor with at least one transmission, which is connected to the drive motor as a combined unit and forms a drive motor-transmission unit, wherein The drive motor-gear unit has a rotatable shaft 4 on its two axial end regions, which can be driven via at least one gear to adjust the air-guiding element 3 .

[0036] In this case, the corresponding shaft 4 drives a mechanical device 5 , which actuates levers 6 arranged thereon on both sides of the air-guiding element in order to raise and lower the air-guiding element 3 .

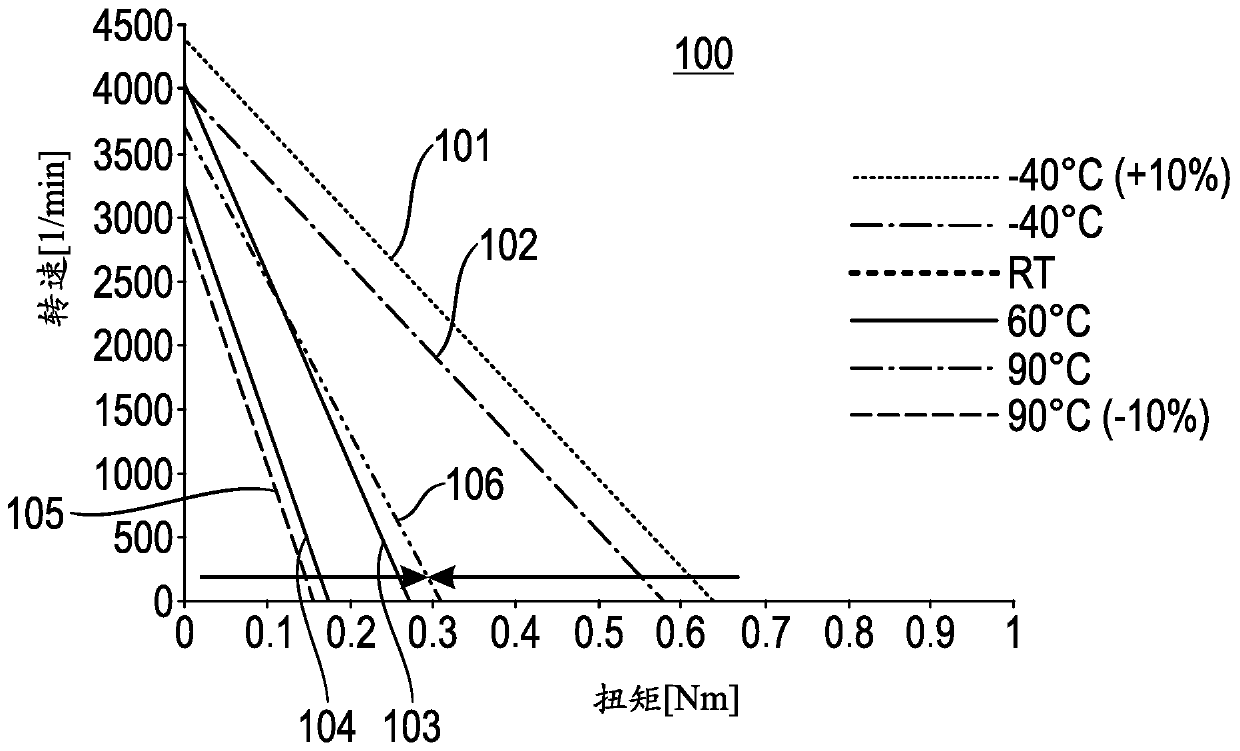

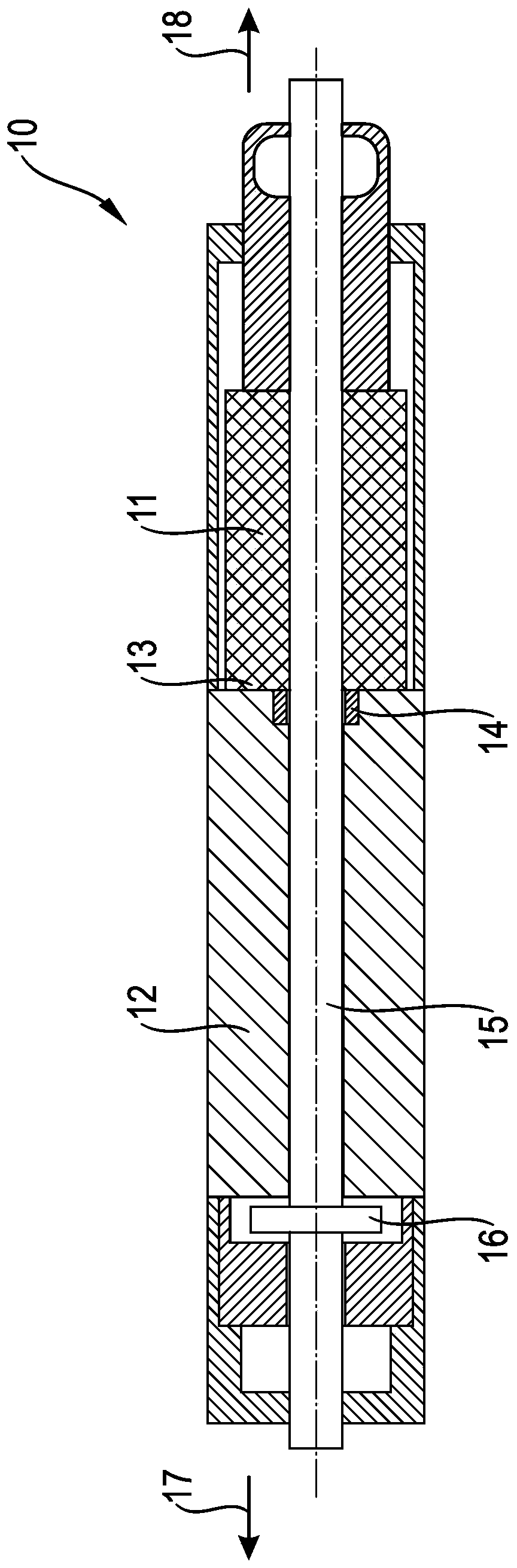

[0037] figure 2 Shown is an embodiment of a drive unit 10 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com