A device for recycling and removing paint from construction waste steel structures

A technology for construction waste and steel structures, which is applied in the directions of cleaning methods using liquids, metal processing equipment, cleaning methods and utensils, etc., which can solve the problems of inconvenient paint recovery, inability to remove paint on the surface of building steel structures, and low paint removal efficiency. , to achieve the effect of efficient paint stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

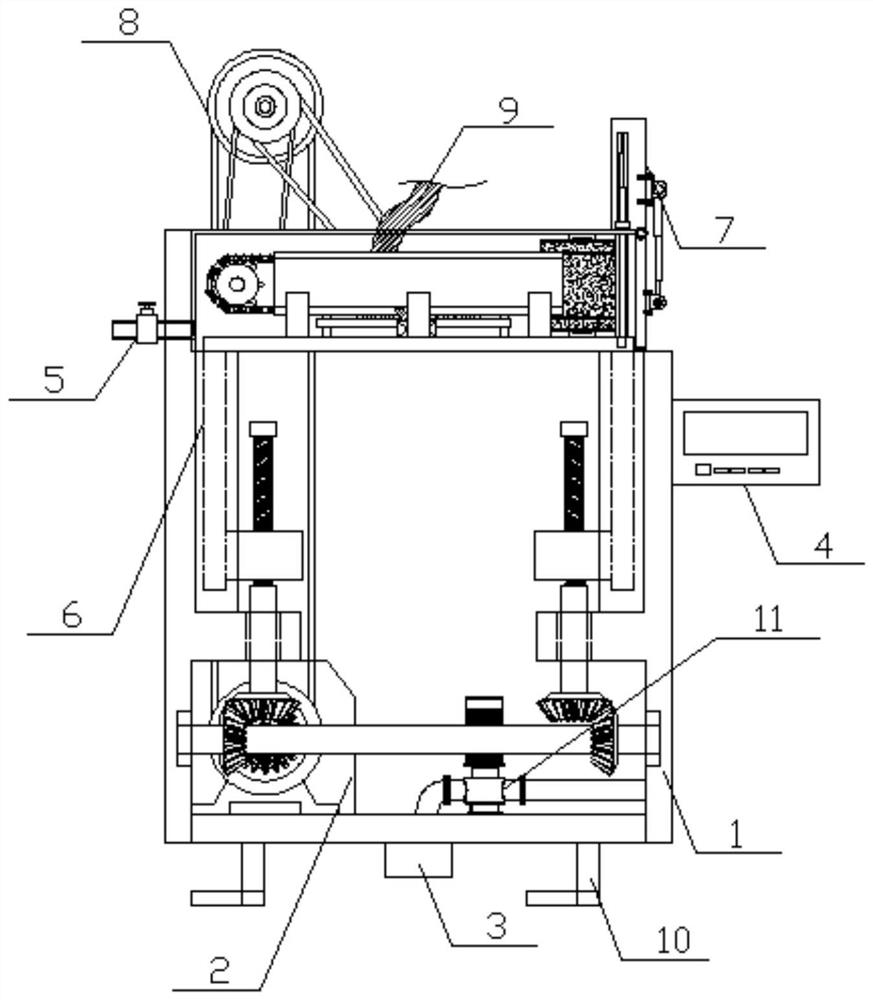

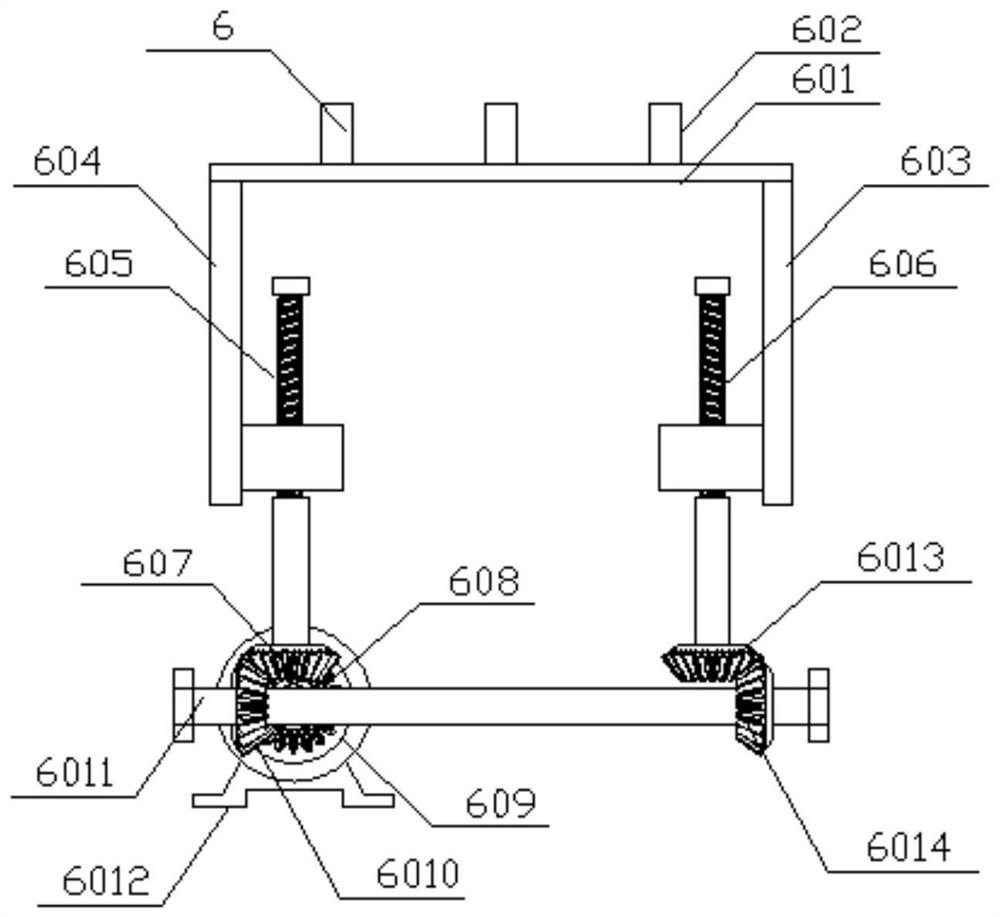

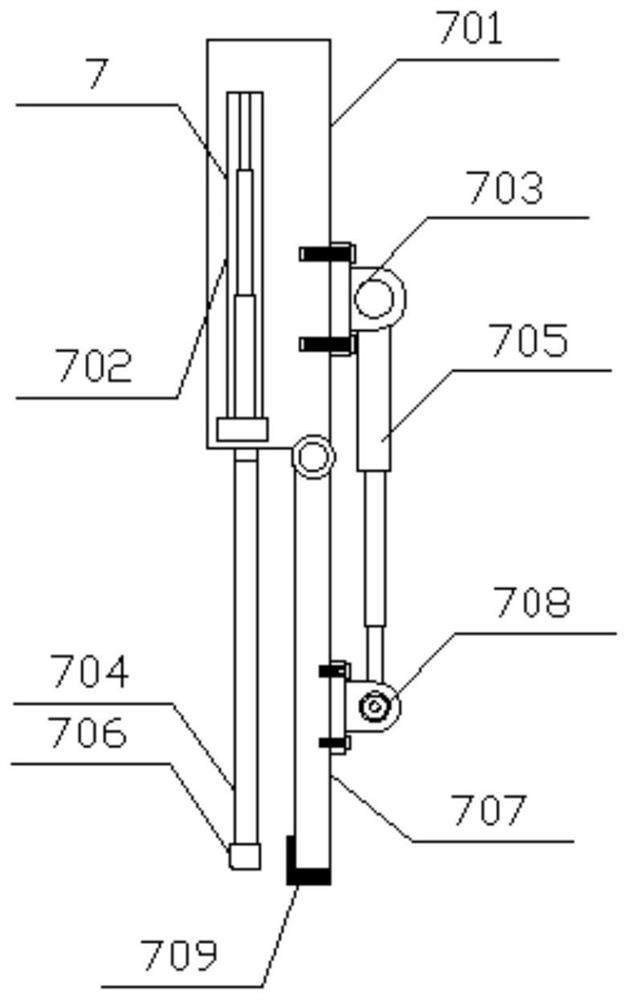

[0025] In this technical solution:

[0026] Soaking mechanism-6, baffle mechanism-7, scrubbing mechanism-8, recovery mechanism-9, support platform-601, support frame-602, first support plate-603, second support plate-604, first screw rod- 605, the second screw rod-606, the first bevel gear-607, the second bevel gear-608, the first pulley-609, the third bevel gear-6010, the transmission rod-6011, the motor-6012, the fourth bevel gear- 6013, the fifth bevel gear-6014, the gantry-701, the first micro-push rod-702, the first bearing seat-703, the baffle-704, the second micro-push rod-705, the silicone sleeve-706, the turn plate- 707, second bearing seat-708, silicone pad-709, second pulley-801, third pulley-802, fourth pulley-803, first gear-804, chain-805, shaft block-806, frame-807 , Steel wire mechanism-808, gear rod-901, second gear-902, fifth pulley-903, sewage suction port-904, sewage suction pipe-905, first fixed seat-906, second fixed seat-907 The invention contains subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com