Horizontal jack fixing support

A technology for fixing brackets and jacks, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of jack shaking, increasing the expansion degree of the jack, and wasting space on the trunk floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

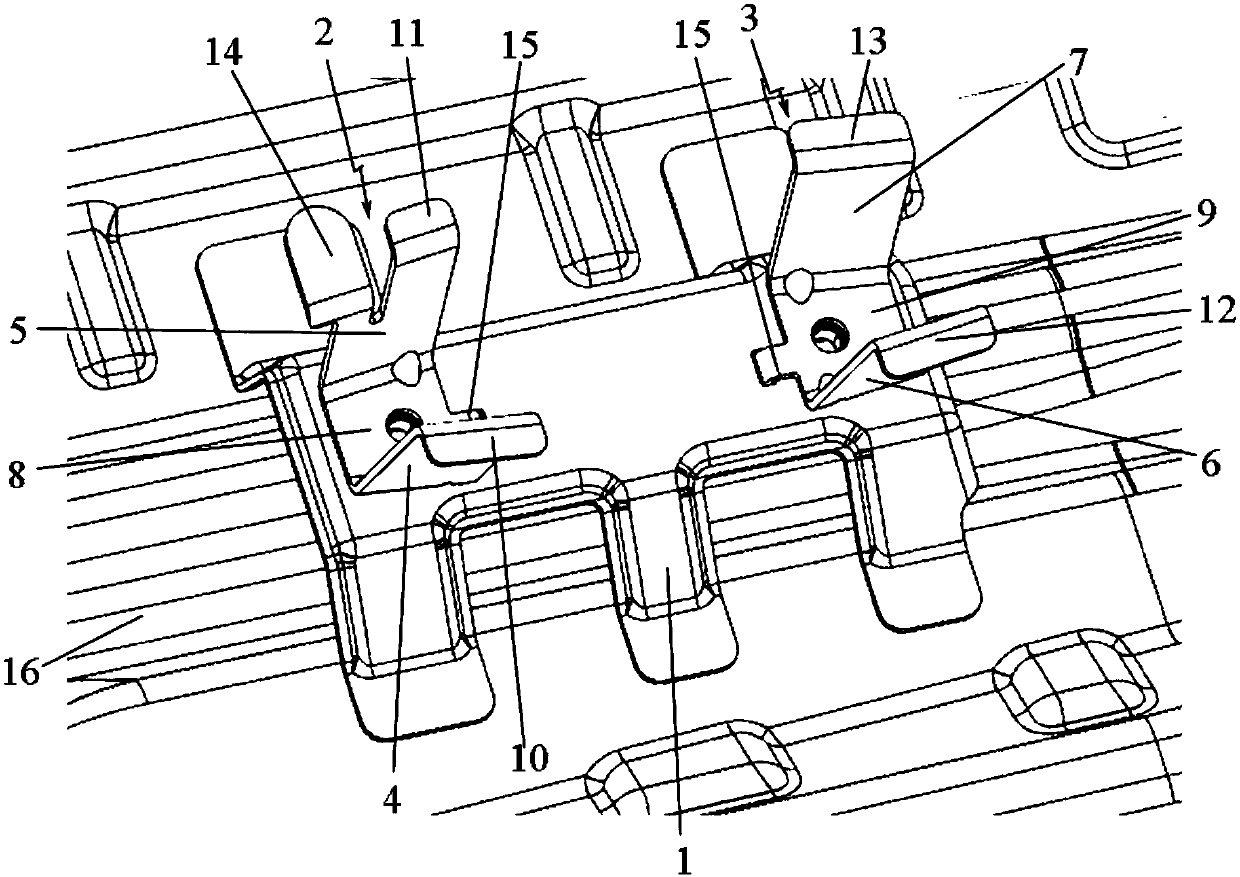

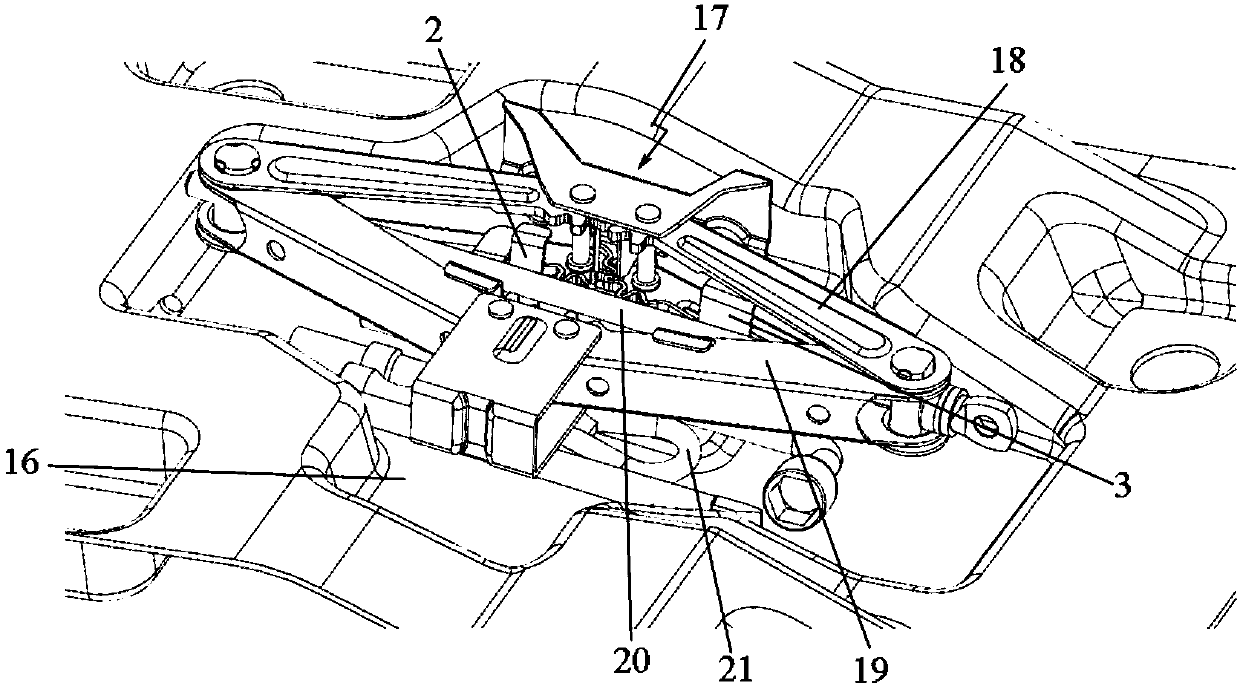

[0026] Attached below figure 1 to attach figure 2 , a horizontal jack fixing bracket of the present invention will be further described in detail.

[0027] Those of ordinary skill in the art can understand that the terms "upper" and "lower" used in this specification refer to the relative positional relationship in the vertical direction; "left" and "right" refer to the relative positional relationship in the horizontal direction; "front" , "Back" refers to the vertical relative positional relationship.

[0028] A kind of horizontal jack fixing bracket of the present invention, please refer to Figure 1 to Figure 2, comprising a first claw 2 and a second claw 3 oppositely arranged left and right, the first claw 2 and the second claw 3 are all fixed on the rear floor, the first claw 2 and the The second claw 3 is provided with a U-shaped groove, and the screw 20 in the middle of the jack is arranged in the U-shaped groove of the first claw 2 and the second claw 3, and the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com