Electrostatic absorption traction device for air bubble film coiled materials

A traction device and electrostatic adsorption technology, which is applied in the field of electrostatic adsorption traction devices for foam film coils, can solve the problems of high labor intensity, low efficiency, and high production costs, and achieve the effects of reducing labor, reducing production costs, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, Features and their functions are described in detail below.

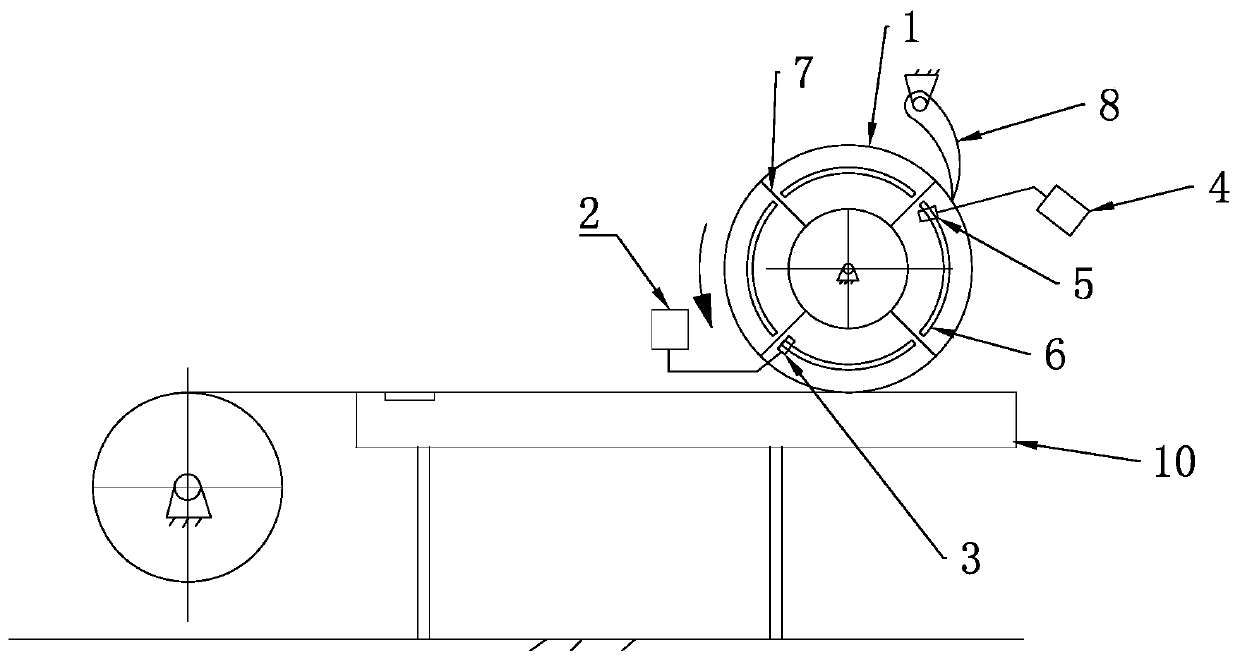

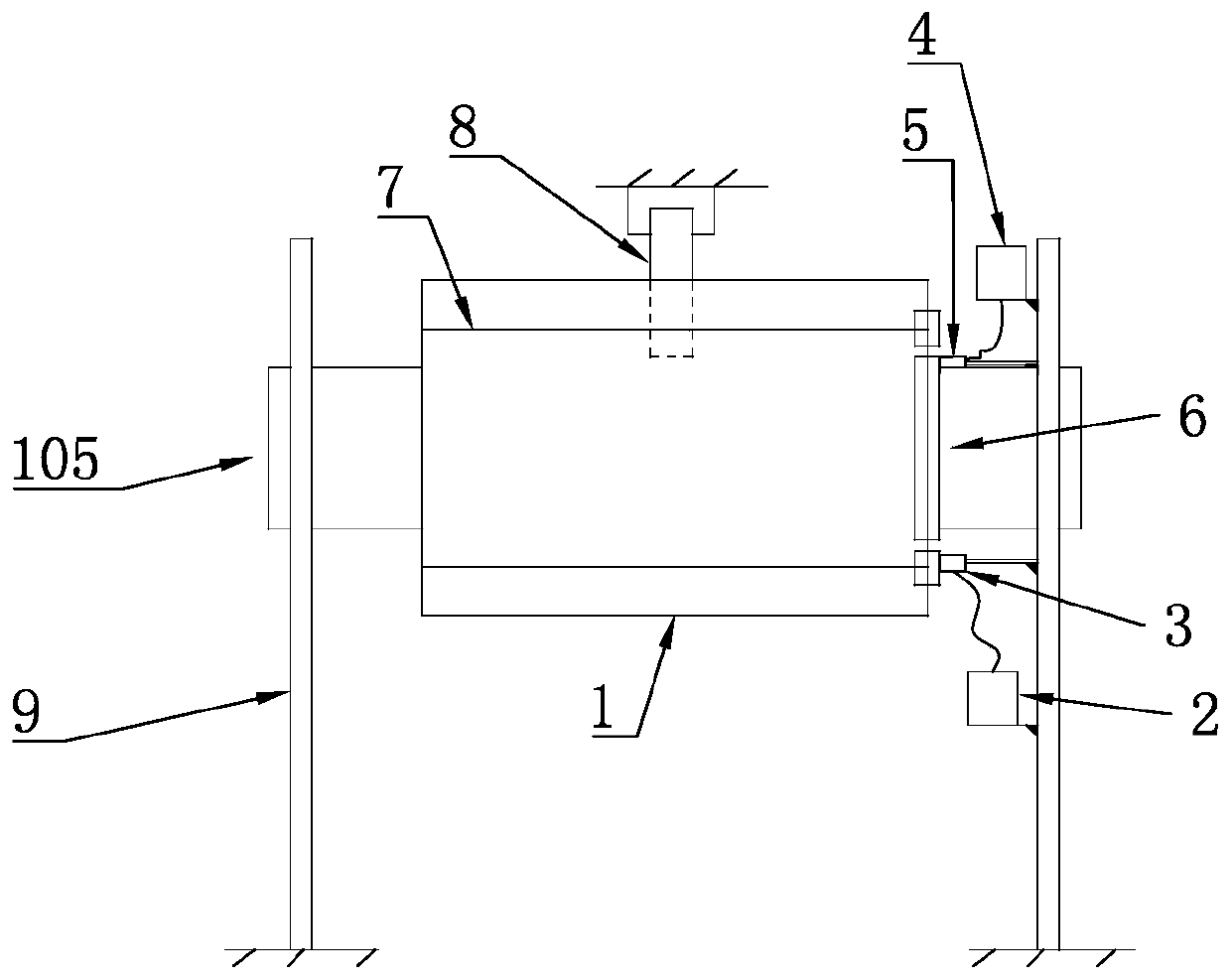

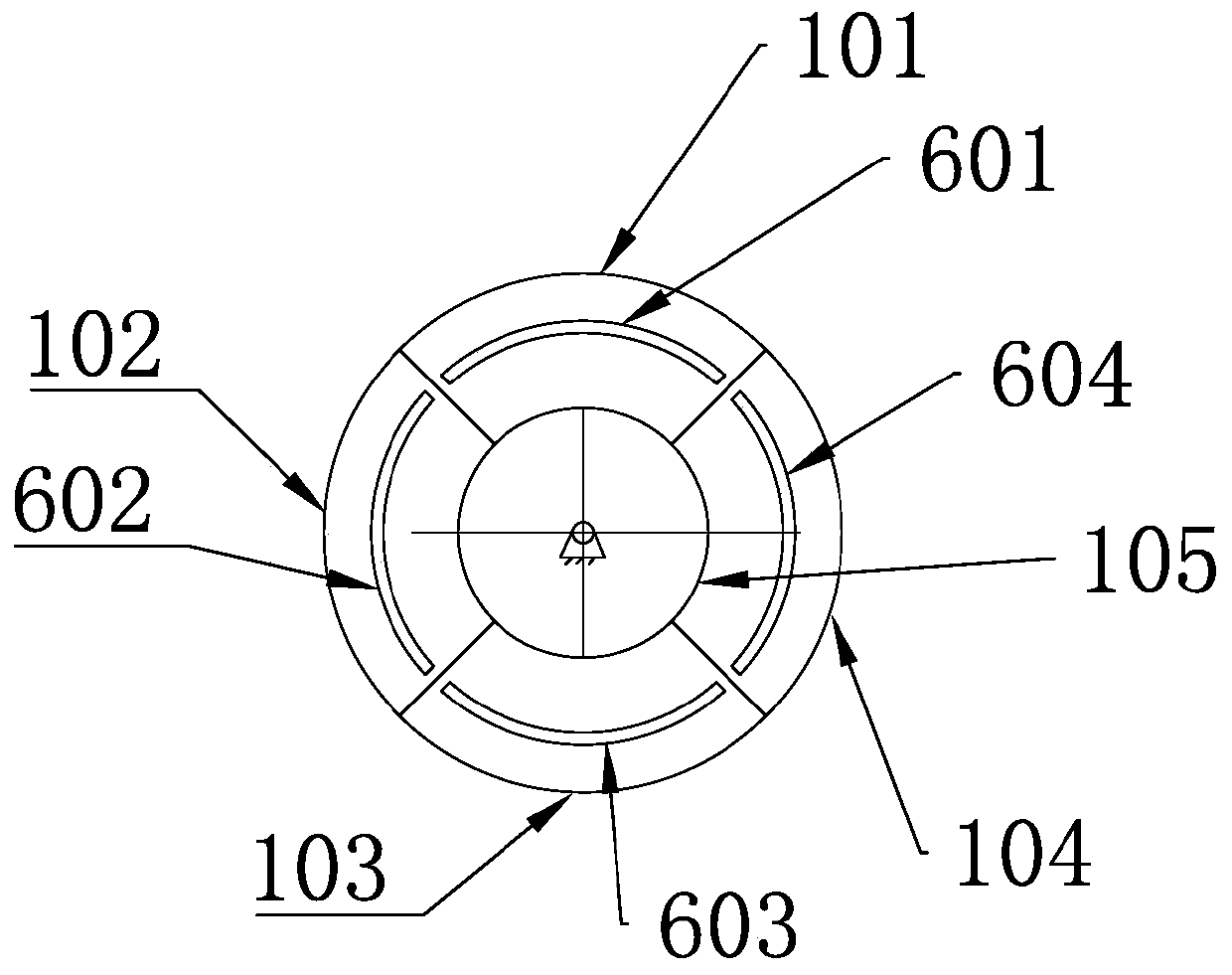

[0016] see Figure 1 to Figure 2 , an electrostatic adsorption traction device for foam film coils, comprising a conductive roller 1, a static generator 2, a static brush 3, a static eliminator 4, a static elimination brush 5 and a scraper 8; the conductive roller 1 is built with an insulating The roller 105, the insulating roller 105 is installed on the frame 9 through bearings, the conductive roller 1 is built with a plurality of insulating sheets 7 extending in the axial direction, and the insulating sheet 7 evenly divides the conductive roller 1 into multiple parts. regions, see image 3 , the number of the insulating sheet 7 in this embodiment is four, and the four insulating sheets 7 divide the conductive roller 1 into the conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com