Bidirectional parallel riveting device

A technology of rivets and riveting machines, which is applied in the field of mechanical processing, can solve the problems of increased space occupied by rivet devices, increased enterprise site costs, and cumbersome riveting processes, and achieve the effects of saving working time, improving work efficiency, and reducing site costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

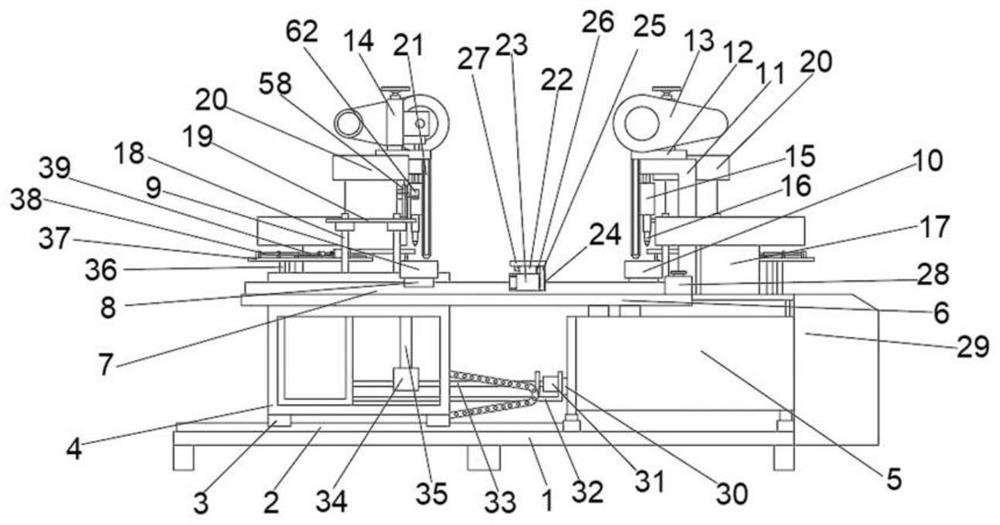

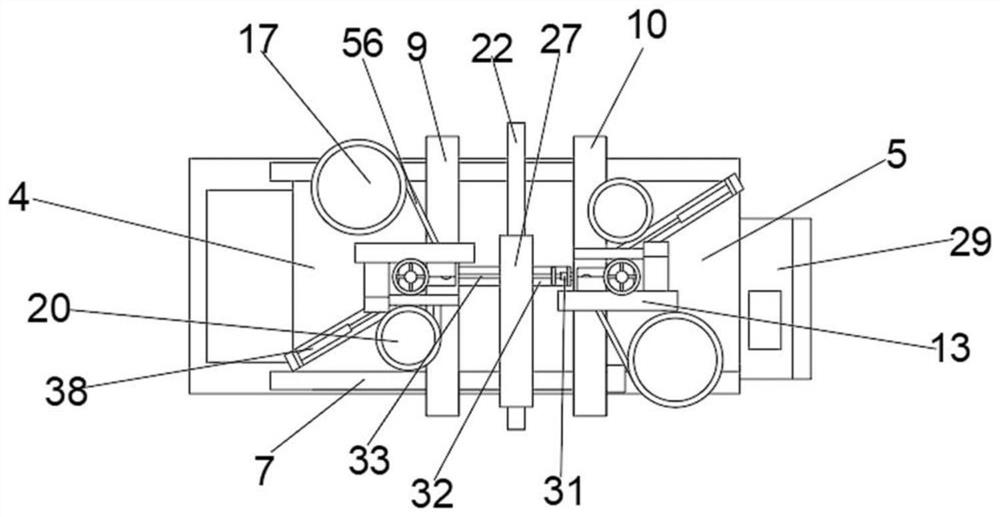

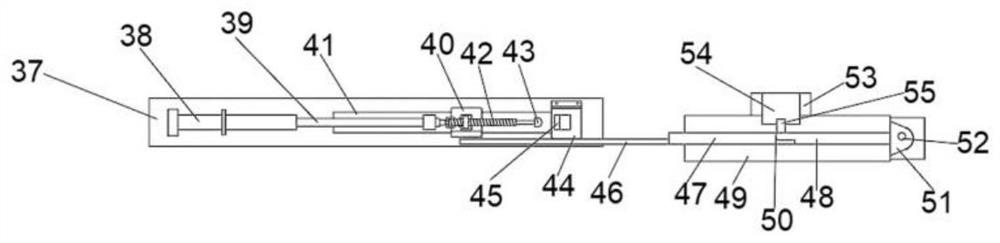

[0044] According to the research and analysis of the applicant, the existing riveting device usually adopts a single-sided riveting method when riveting plates. After completing the riveting of one side of the plate, the position of the plate is adjusted to turn the plate over, and then the other side is riveted. , resulting in cumbersome riveting process and low efficiency. At the same time, when riveting in a pneumatic way, an air compressor is installed on the rivet device to provide pneumatic power. The air compressor is usually large in size, which will increase the overall floor space of the rivet device. Further increase the site cost of the enterprise, so it is urgent to design a two-way parallel rivet device to rivet both sides of the plate at the same time, improve the rivet efficiency of the plate, reduce the volume of the rivet device at the same time, reduce the floor space of the rivet device, and save the enterprise The site cost required for this.

[0045] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com