Forked automatic detection and acceptance device capable of directionally collecting abnormal parts

An automatic detection and motion device technology, applied in sorting and other directions, can solve problems such as low production efficiency, low degree of automation, and off-light bulbs, and achieve the effect of improving service life and low failure rate of power connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

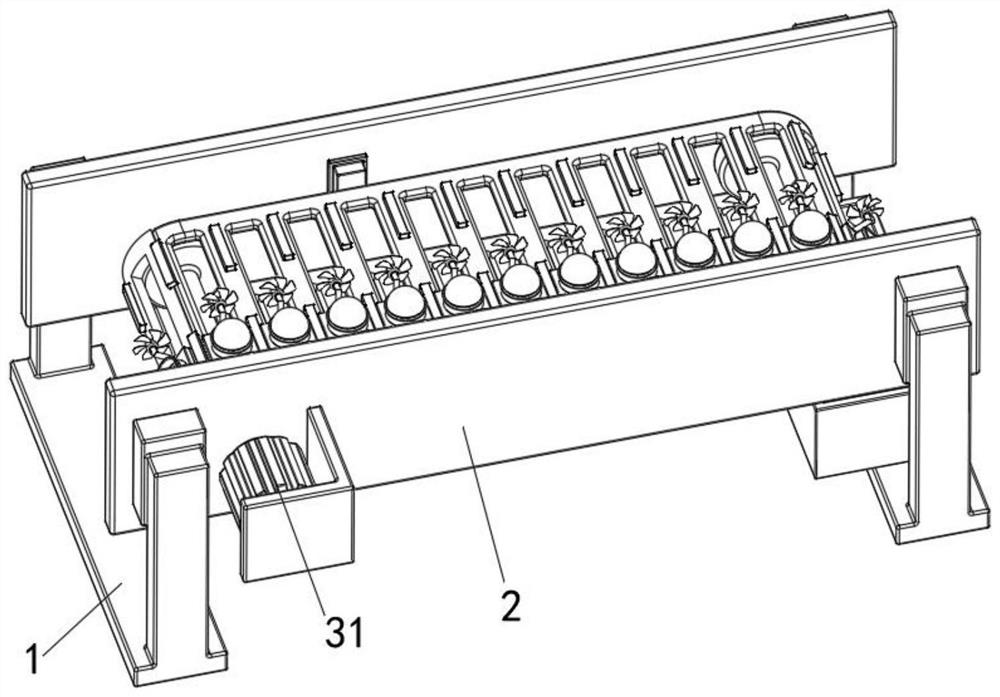

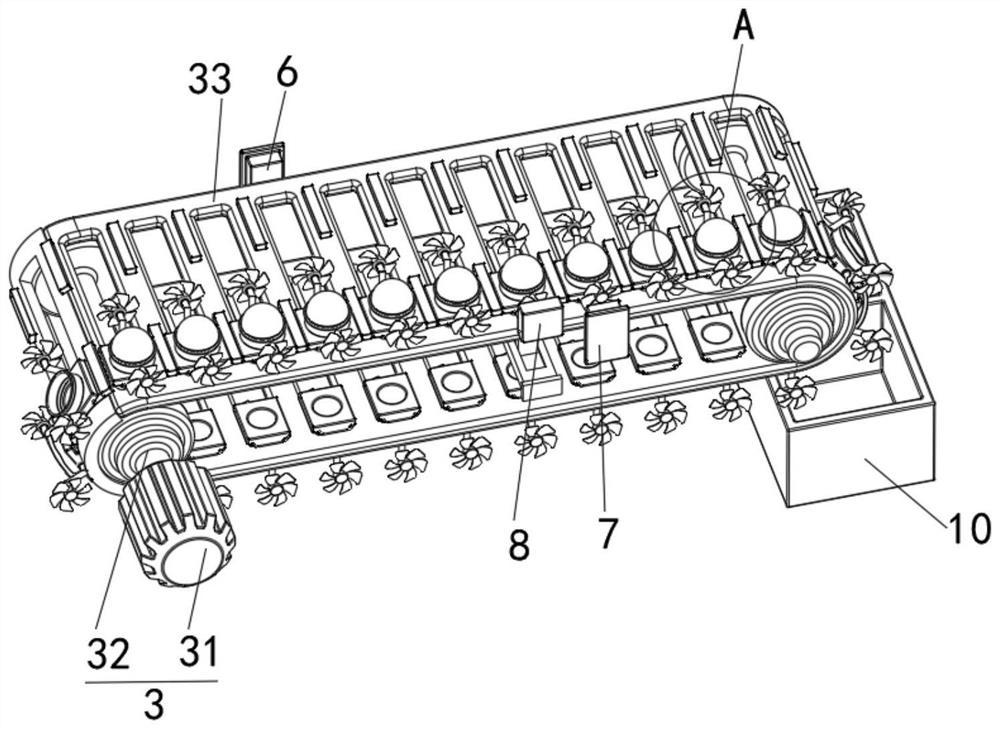

[0037] see Figure 1-Figure 8 , a bifurcated automatic detection and acceptance device for directional collection of abnormal parts, comprising a support leg 1, the inner side of the support leg 1 is fixedly connected with a baffle plate 2, and the side of the baffle plate 2 away from the support leg 1 is provided with a moving device 3, A control device 4 is fixedly installed on the movement device 3, the baffle plate 2 is symmetrically arranged on the front and rear sides of the support foot 1, and the rear side of the front side baffle plate 2 is fixedly connected with an electrical connection device 5;

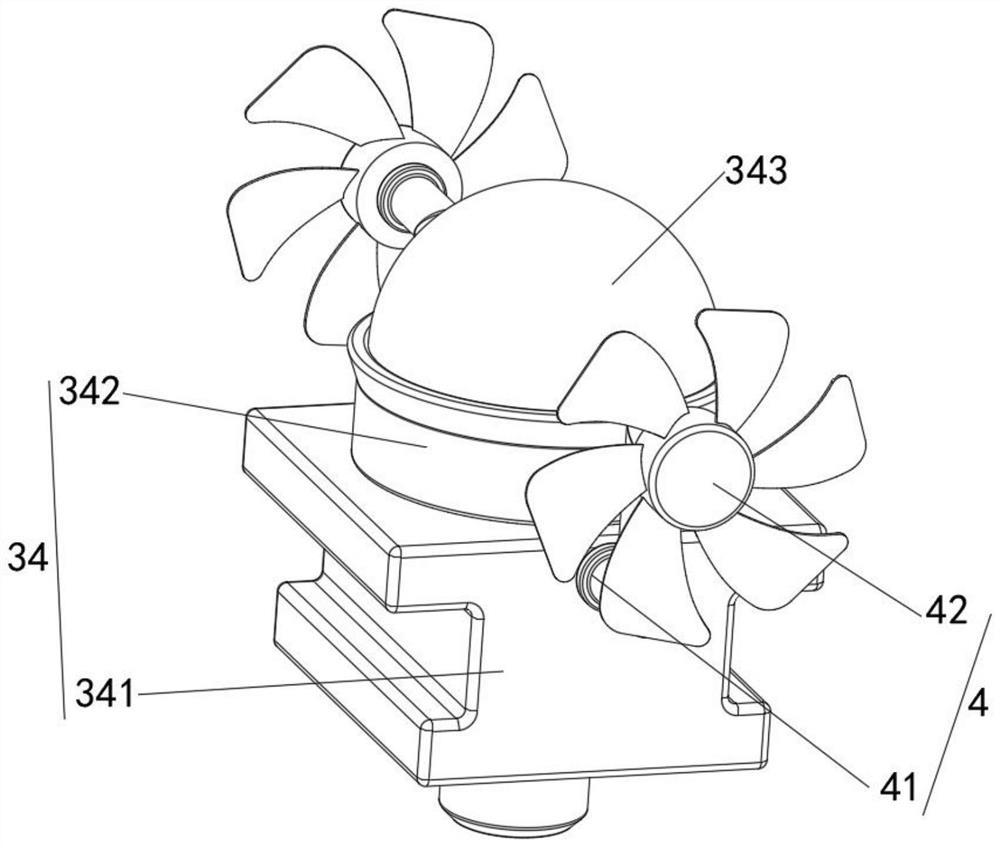

[0038] Motion device 3 comprises motor 31, rotating wheel 32, conveyer belt 33 and executive device 34, and the front side of front side baffle plate 2 is fixedly connected with motor 31 by L-shaped plate, and the rear side of motor 31 is connected with rotating wheel 32 in rotation, and rotates A conveyor belt 33 is rollingly connected to the axially outer side of the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com