Full-automatic construction machine for near-surface embedded FRCM reinforcing beam type component

An embedded and reinforced beam technology, which is applied in building construction, building maintenance, construction, etc., to achieve the effect of ensuring construction efficiency and reinforcement quality, saving manpower, material resources and repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

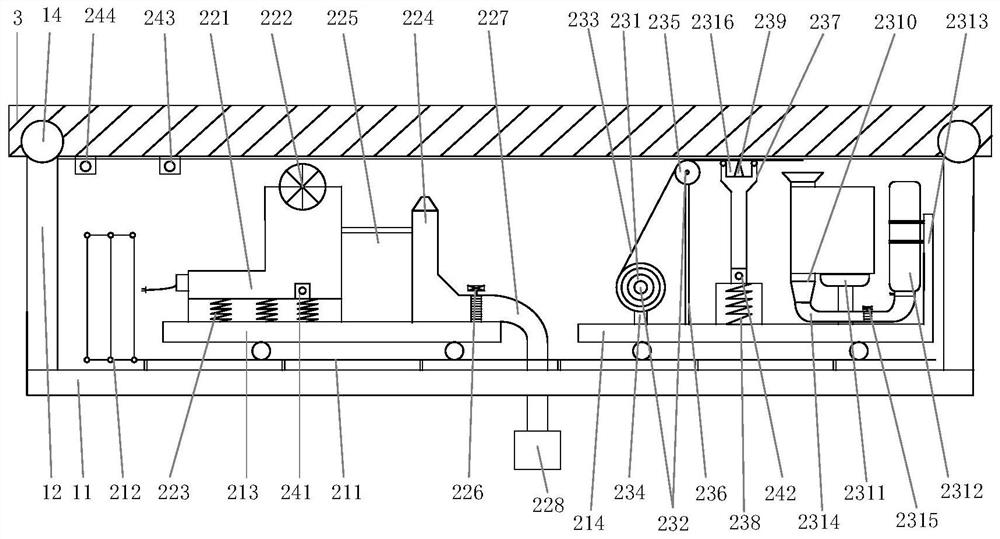

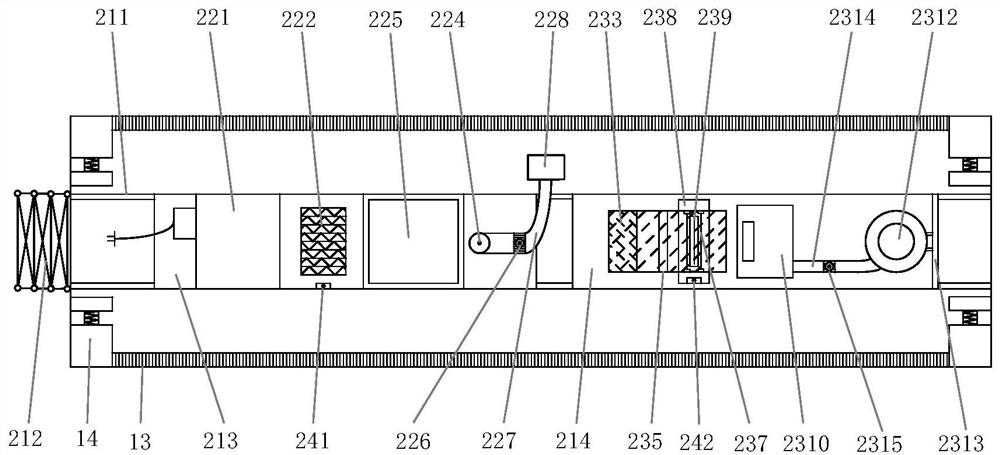

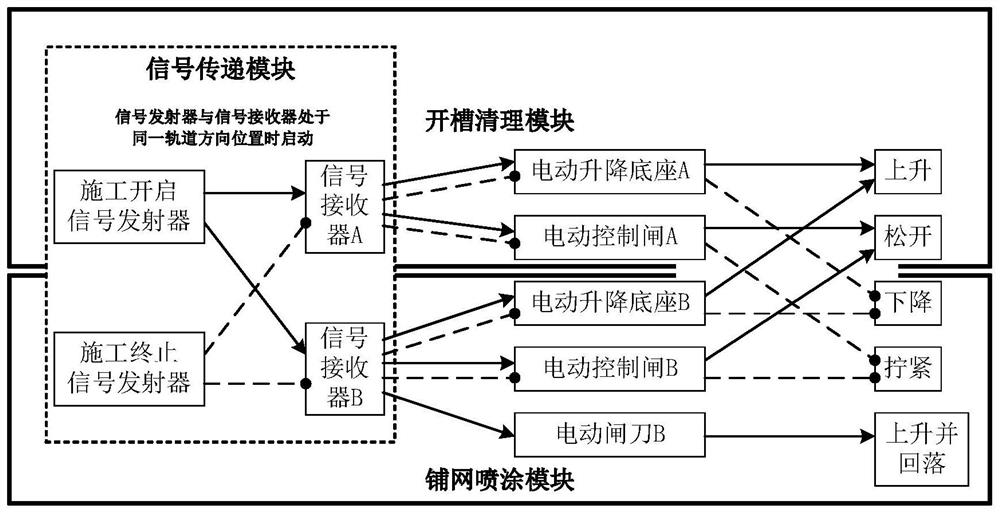

[0031] The technical solutions provided by the present application will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present application will become clearer in conjunction with the following description.

[0032] It should be noted that the embodiments of the present application have better implementability, and are not intended to limit the present application in any form. The technical features or combinations of technical features described in the embodiments of the present application should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. The scope of the preferred embodiments of the present application may also include other implementations, which should be understood by those skilled in the art to which the embodiments of the present application belong.

[0033] Techniques, methods and devices known to those of ordinary skill in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com