Full-automatic construction machine of carbon fiber cloth reinforced high-pile wharf beam-type element

A carbon fiber cloth and beam-type member technology, which is applied in the field of automatic construction machines, can solve the problems of inconvenience of carbon fiber reinforcement, save manpower, material resources, time, and ensure efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

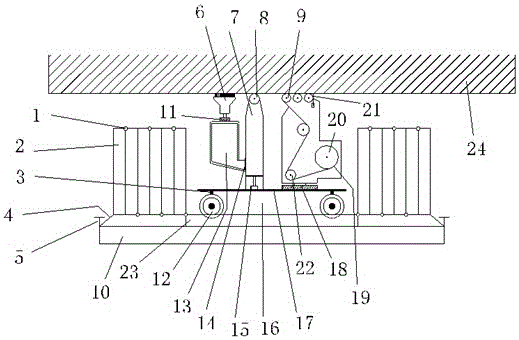

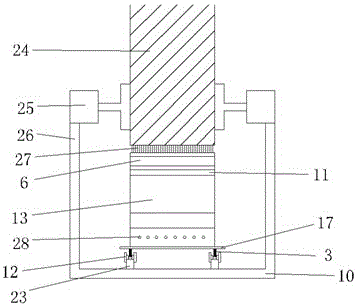

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] like figure 1 and 2 As shown, a fully automatic construction machine for beam-type components of high-pile wharf reinforced with carbon fiber cloth, including an external fixed support module and an internal walking construction module. The construction module provides support, and the external fixed support module includes a hydraulic rod fixing device 25, a support base plate 10 and an external fixed support module box wall 26, and an external fixed support module box wall 26 is installed on the opposite sides of the support base plate 10 , the top of the external fixed support module box wall 26 facing each other is equipped with a hydraulic rod fixing device 25, and the two hydraulic rod fixing devices 25 can fix the beam 24 to be repaired, and the two hydraulic rod fixing devices 25 are symmetrical to each other. The present invention is sent below the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com