Dust removal and windproof moving window

A technology for moving windows and preventing wind, applied in the field of windows, can solve problems such as large wind resistance of casement windows, damage to furniture and floors, and hidden safety hazards, and achieve the effects of ensuring indoor temperature, reducing cleaning difficulty, and improving sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

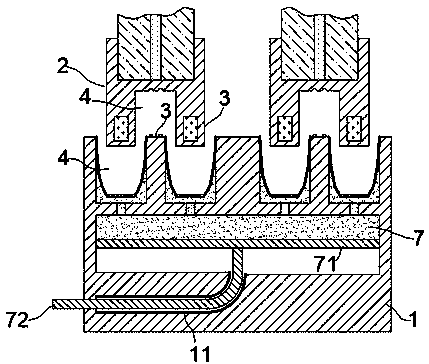

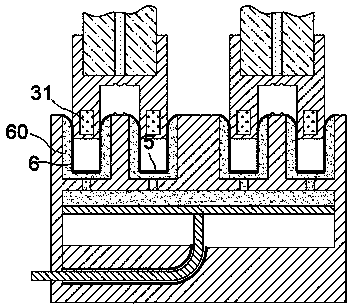

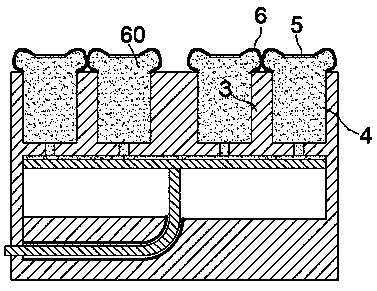

[0016] exist Figure 1 to Figure 3 In the shown embodiment, the dust-removing and anti-wind shifting window includes a window frame 1 and a window form 2, and matching slide rails 3 and chute 4 are arranged on the upper and lower frame surfaces of the window frame 1 and form 2, so that Said window 2 can reciprocate and translate under the matching of slide rail 3 and chute 4;

[0017] In the chute 4 of the upper and lower frame surfaces of the window frame 1, a support plate 5 parallel to the bottom surface of the chute 4 is provided, and the edge of the support plate 5 is connected with the edge of the chute 4 through a flexible sealing layer 6; the sealing layer 6. The support plate 5 and the chute 4 form an airtight closed cavity 60;

[0018] A regulating cavity 7 is provided in the window frame 1, and the regulating cavity 7 includes a piston plate 71 capable of reciprocating translation along the inner wall of the regulating cavity 7, and a control plate 72 of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com