Connecting rod used for engine crankshaft

An engine and connecting rod technology, applied in the direction of engine components, connecting rods, shafts, etc., can solve the problems of large force on the tightening screw, easy damage, affecting the service life of the connecting rod, etc., and achieve the effect of improving the service life and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known circuits, components, methods and processes will not be described in detail below.

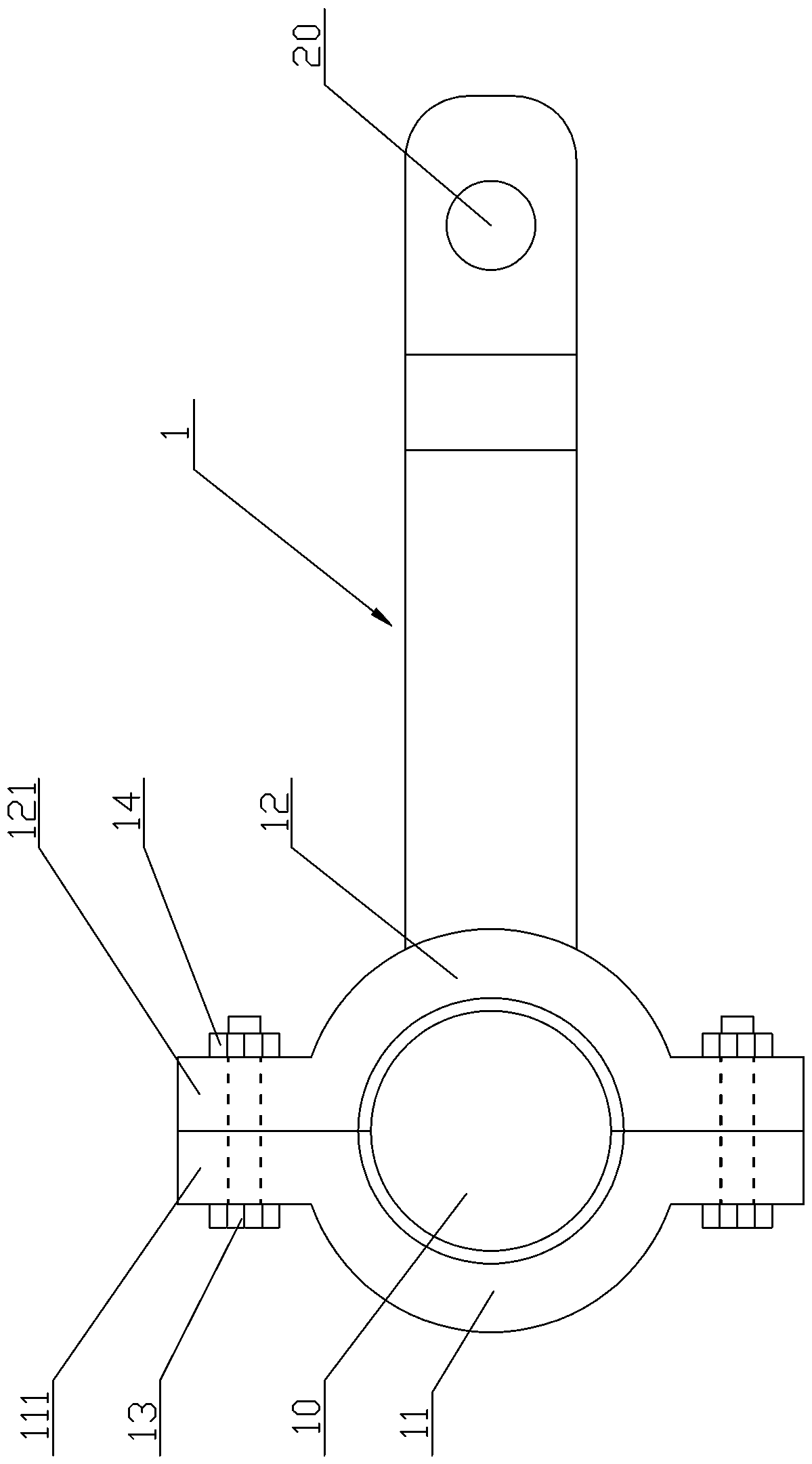

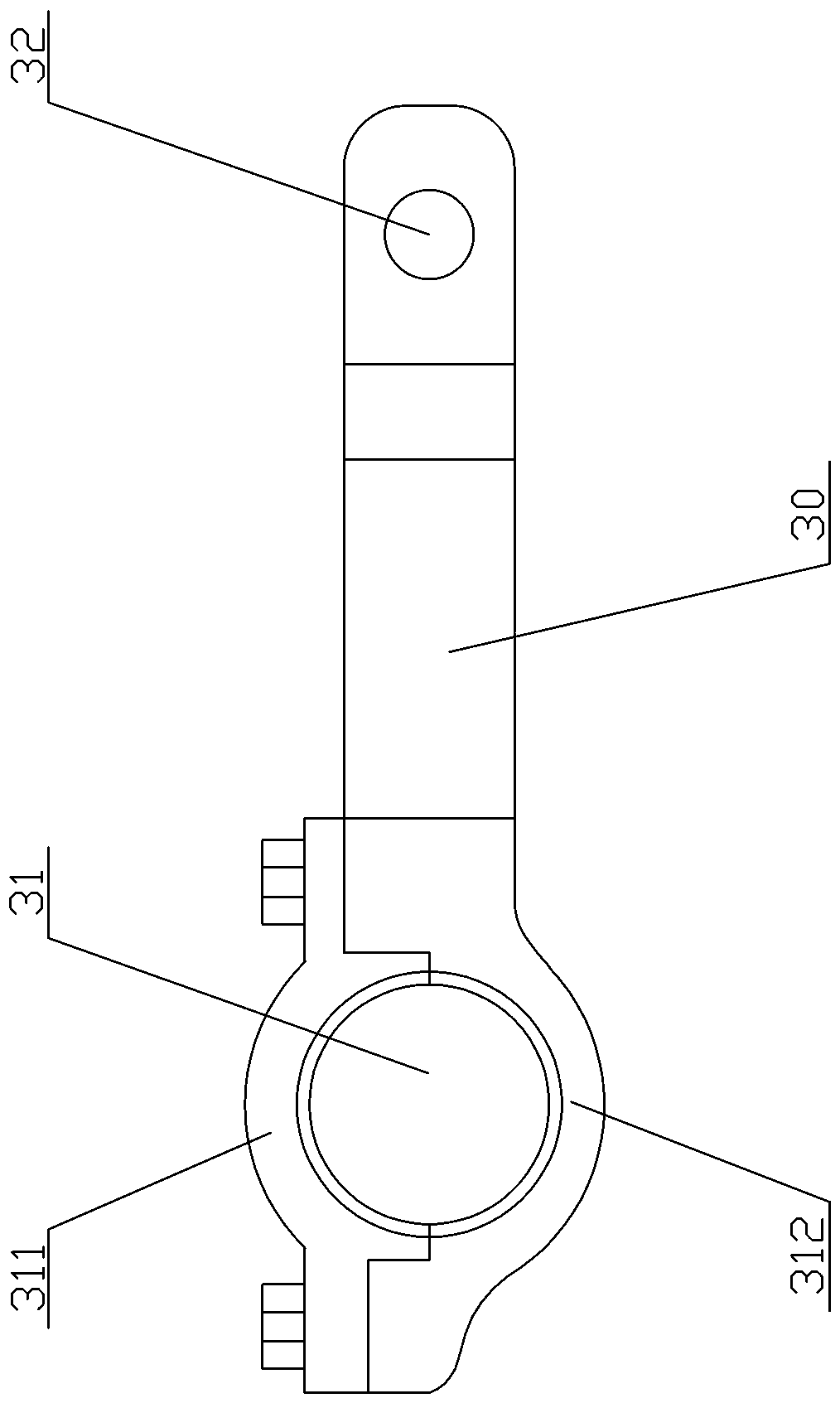

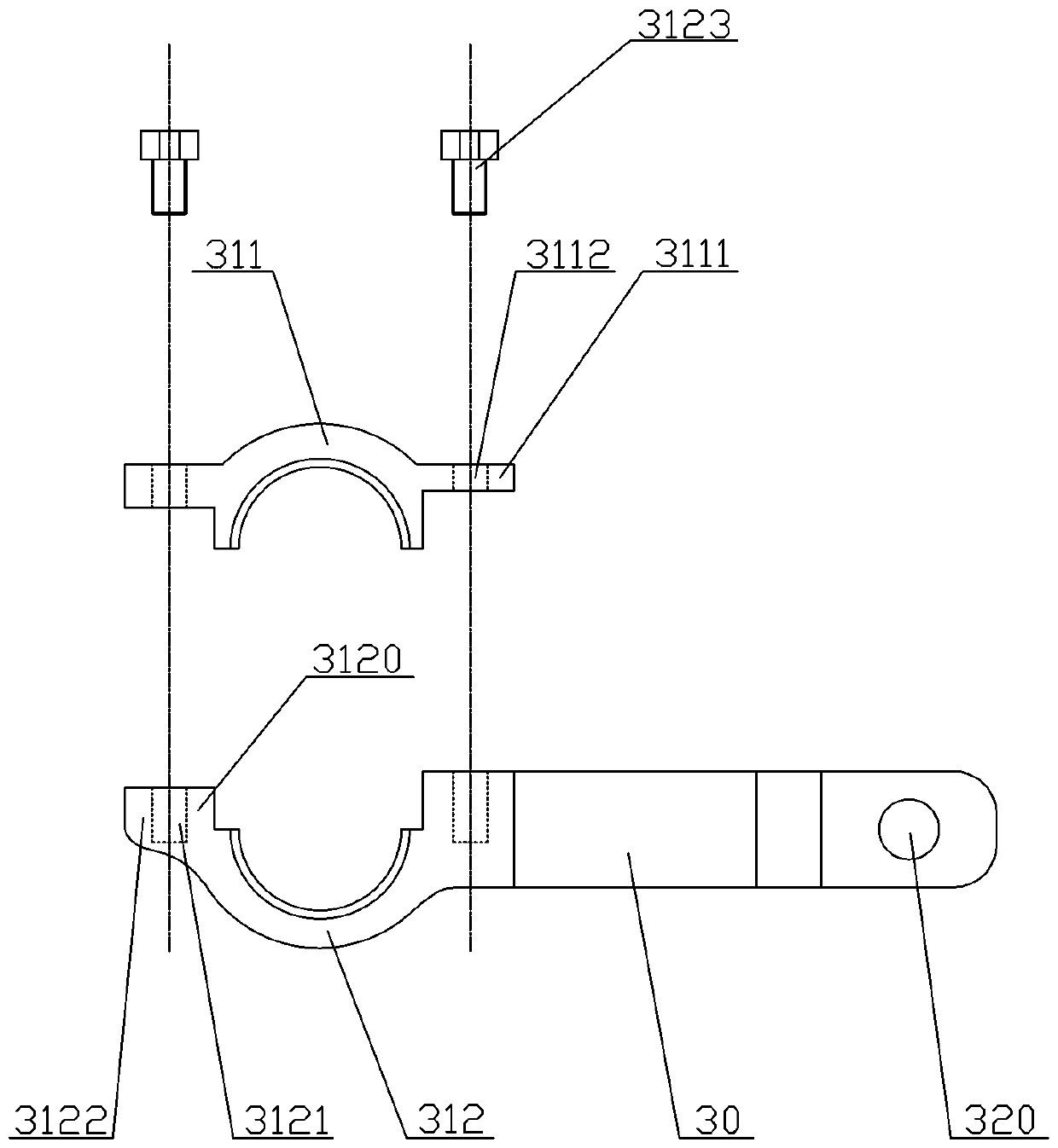

[0017] A connecting rod used on an engine crankshaft, refer to Figure 2 to Figure 4 , including a connecting rod main body 30, the two ends of the connecting rod main body 30 are respectively provided with a large end hole 31 and a small end hole 32, and the large end hole 31 is connected with the connecting rod journal of the crankshaft. Wherein the big head hole 31 is made up of upper semicircular groove body 311 and lower semicircular groove body 312. Sections are parallel. The left and right sides of the lower semicircular tank body 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com