Electric heating method and electric heating driving circuit

A driving circuit and electric heating technology, applied in ohmic resistance heating circuit diagrams, ohmic resistance heating, electric heating devices, etc., can solve the problems of energy loss and heat generation efficiency to be improved, and achieve the effect of improved thermal efficiency and small equivalent internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

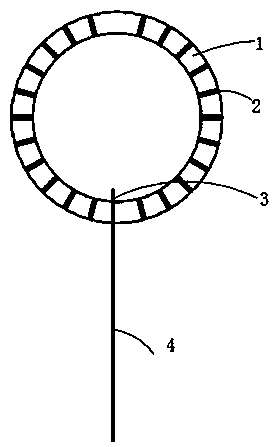

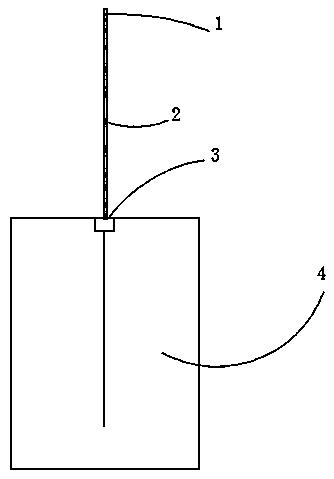

[0027] Present embodiment is a kind of energization to good conductor such as aluminum plate 4, makes such as figure 2 and image 3 The aluminum plate shown has a current flowing through it to generate heat, forming a good conductor heating body (device), which can be used as a heating soleplate of an electric iron, etc.

[0028] In this embodiment, in order to apply power to both ends of a good conductor, the following steps are required:

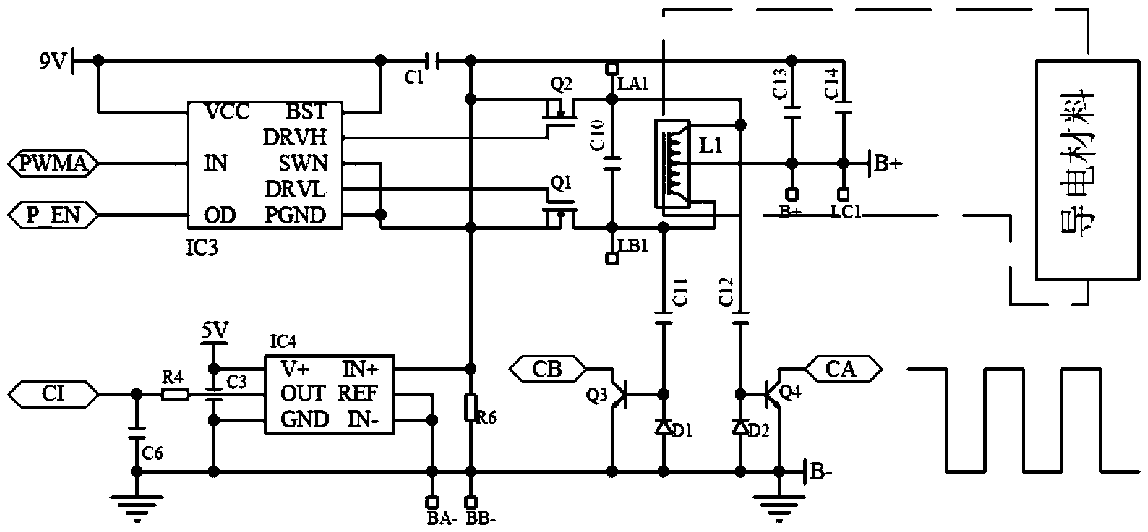

[0029] First, convert the output of the power supply into high-frequency oscillation. This step can add either end of the output end of the power supply to both ends of a coil, and the wire drawn from the middle of the coil is connected to the other end of the power supply to form two loops, and then in each Each controllable switch is set in the circuit. The controllable switch generally uses two MOS tubes, the switch tube Q1 and the switch tube Q2. The two switches are closed in turn, so that the direction of the current in the coil al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com