Special fixture for aluminum profile numerical control machining center

A special fixture and aluminum profile technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor clamping effect, affecting processing accuracy, difficult D-shaped aluminum profile clamping, etc., to achieve clamping effect Good, the effect of improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

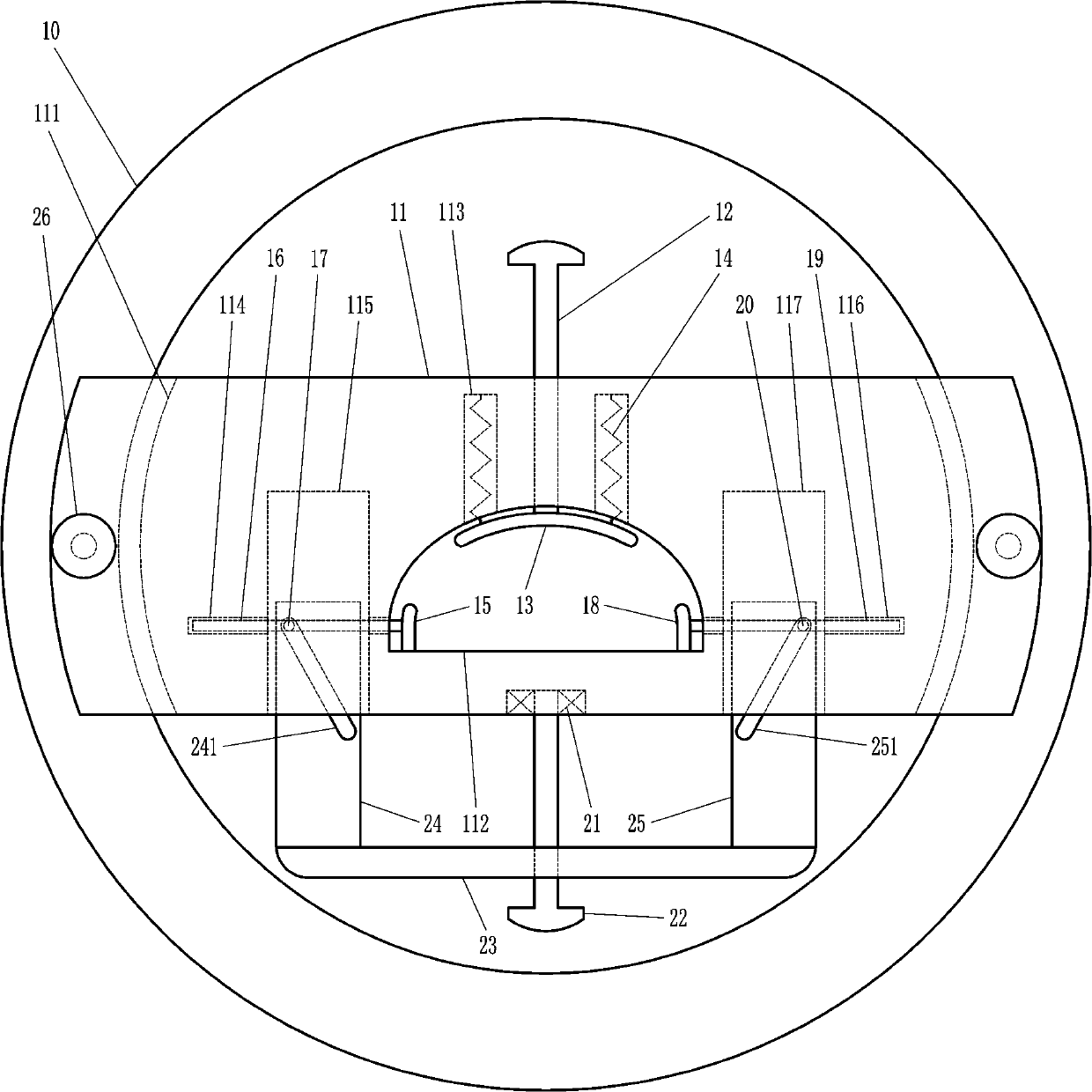

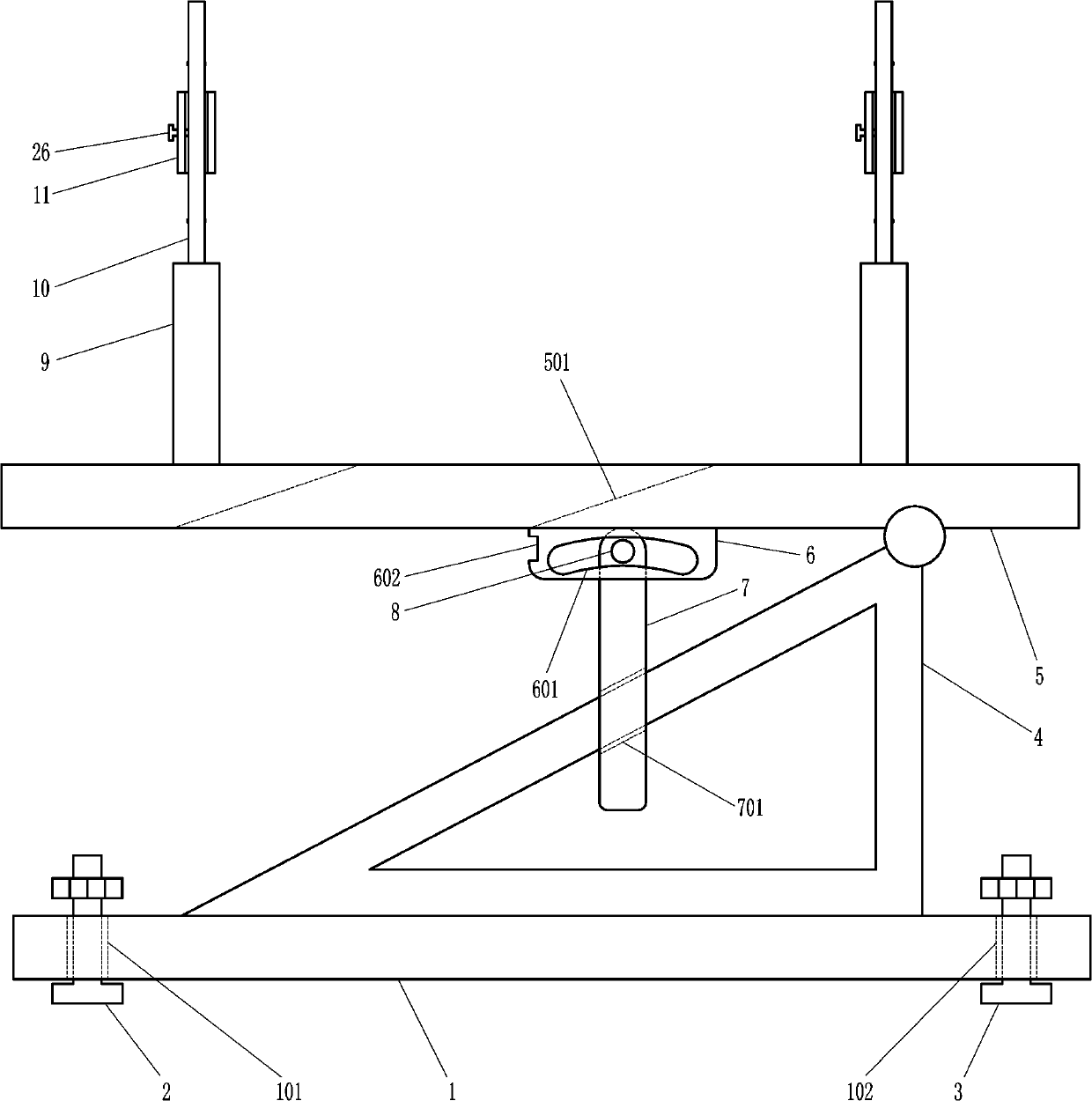

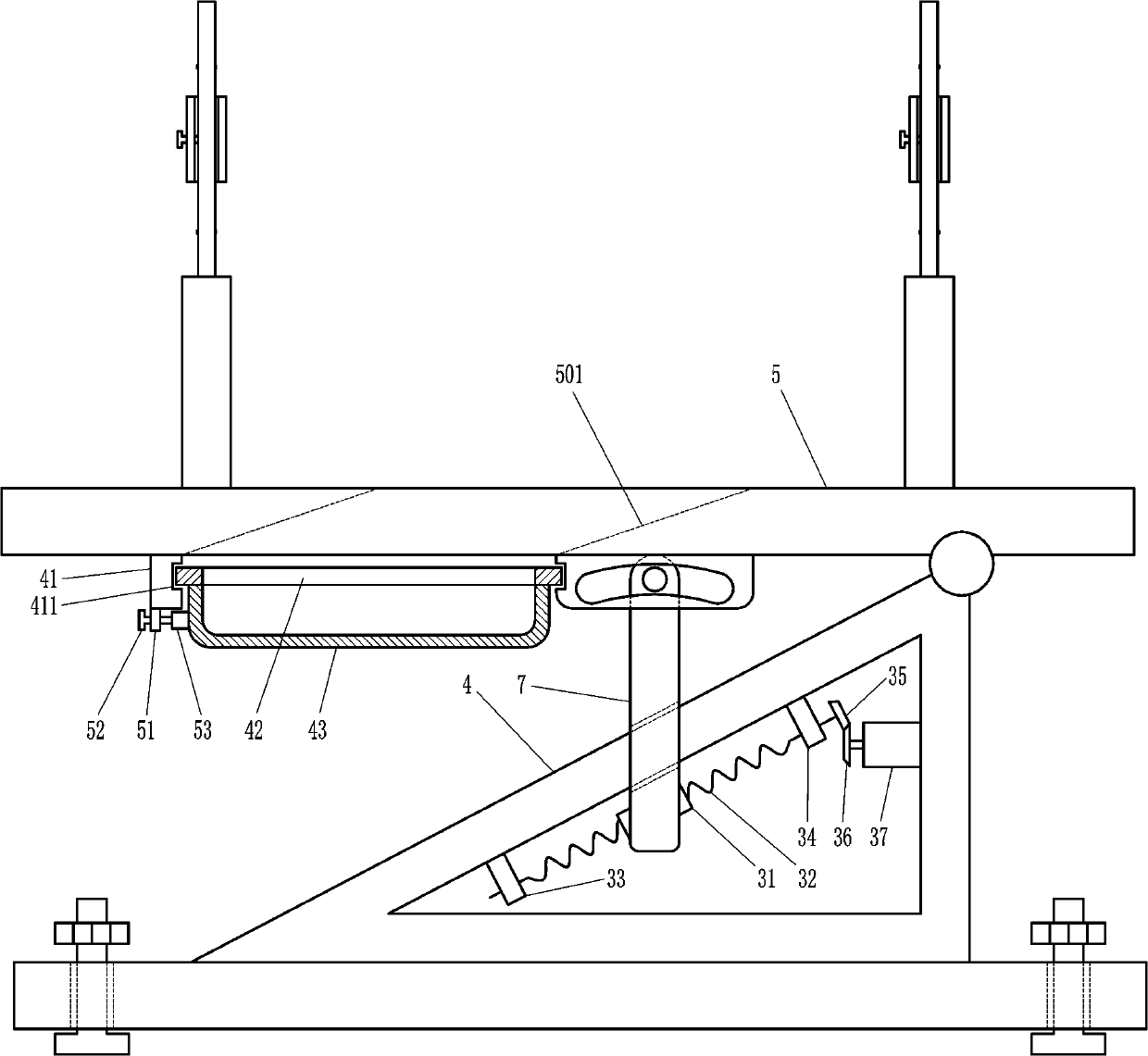

[0019] A special fixture for aluminum profile CNC machining centers, such as Figure 1-3As shown, it includes a base 1, a first large bolt 2, a second large bolt 3, a large triangular support frame 4, a large supporting plate 5, a large connecting plate 6, a movable plate 7, a large pin shaft 8, a support plate 9, a ring Plate 10, rotating plate 11, the first long screw rod 12, large arc pressing plate 13, extension spring 14, the first small pressing plate 15, the first movable rod 16, the first small pin rod 17, the second small pressing plate 18, the second Movable bar 19, the second small pin rod 20, small bearing 21, the second long screw rod 22, small connecting plate 23, the first lifting plate 24, the second lifting plate 25 and small screw rod 26, the left end of base 1 has first Large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is loca...

Embodiment 2

[0021] A special fixture for aluminum profile CNC machining centers, such as Figure 1-3 As shown, it includes a base 1, a first large bolt 2, a second large bolt 3, a large triangular support frame 4, a large supporting plate 5, a large connecting plate 6, a movable plate 7, a large pin shaft 8, a support plate 9, a ring Plate 10, rotating plate 11, the first long screw rod 12, large arc pressing plate 13, extension spring 14, the first small pressing plate 15, the first movable rod 16, the first small pin rod 17, the second small pressing plate 18, the second Movable bar 19, the second small pin rod 20, small bearing 21, the second long screw rod 22, small connecting plate 23, the first lifting plate 24, the second lifting plate 25 and small screw rod 26, the left end of base 1 has first Large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is loc...

Embodiment 3

[0024] A special fixture for aluminum profile CNC machining centers, such as Figure 1-3As shown, it includes a base 1, a first large bolt 2, a second large bolt 3, a large triangular support frame 4, a large supporting plate 5, a large connecting plate 6, a movable plate 7, a large pin shaft 8, a support plate 9, a ring Plate 10, rotating plate 11, the first long screw rod 12, large arc pressing plate 13, extension spring 14, the first small pressing plate 15, the first movable rod 16, the first small pin rod 17, the second small pressing plate 18, the second Movable bar 19, the second small pin rod 20, small bearing 21, the second long screw rod 22, small connecting plate 23, the first lifting plate 24, the second lifting plate 25 and small screw rod 26, the left end of base 1 has first Large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com