A multifunctional fixture for aluminum profile CNC machining center

A multi-functional, aluminum profile technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of narrow application scope and single function, achieve diverse functions, wide application scope, convenient and fast use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

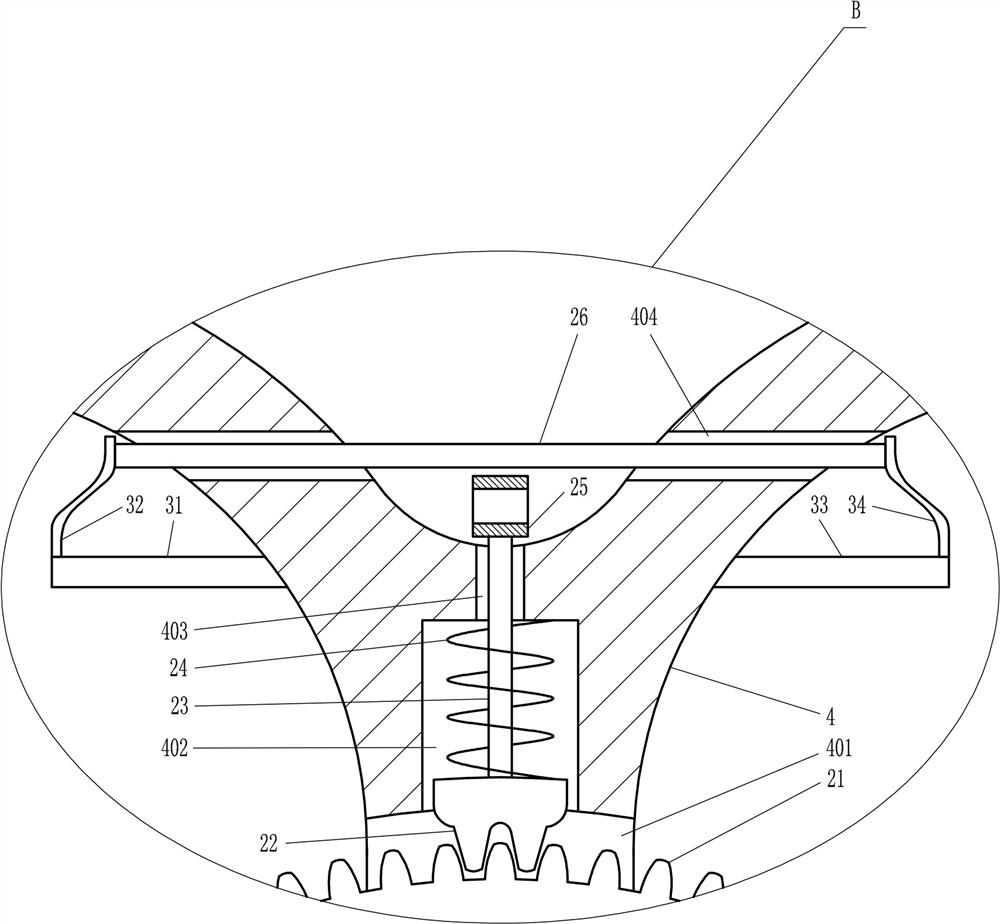

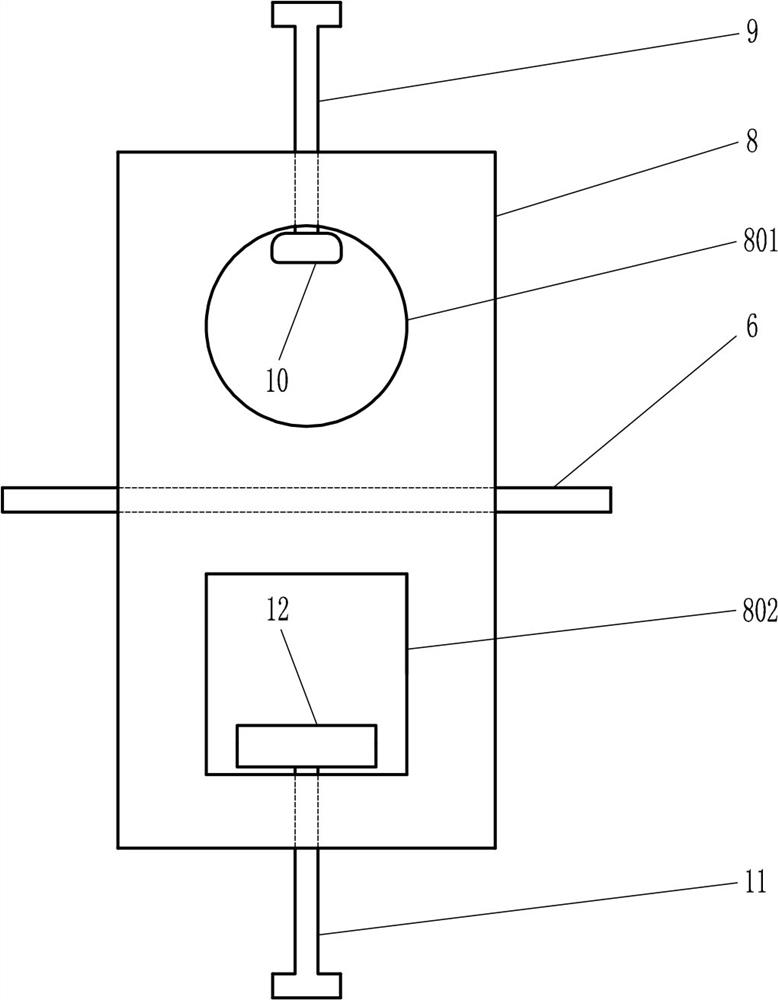

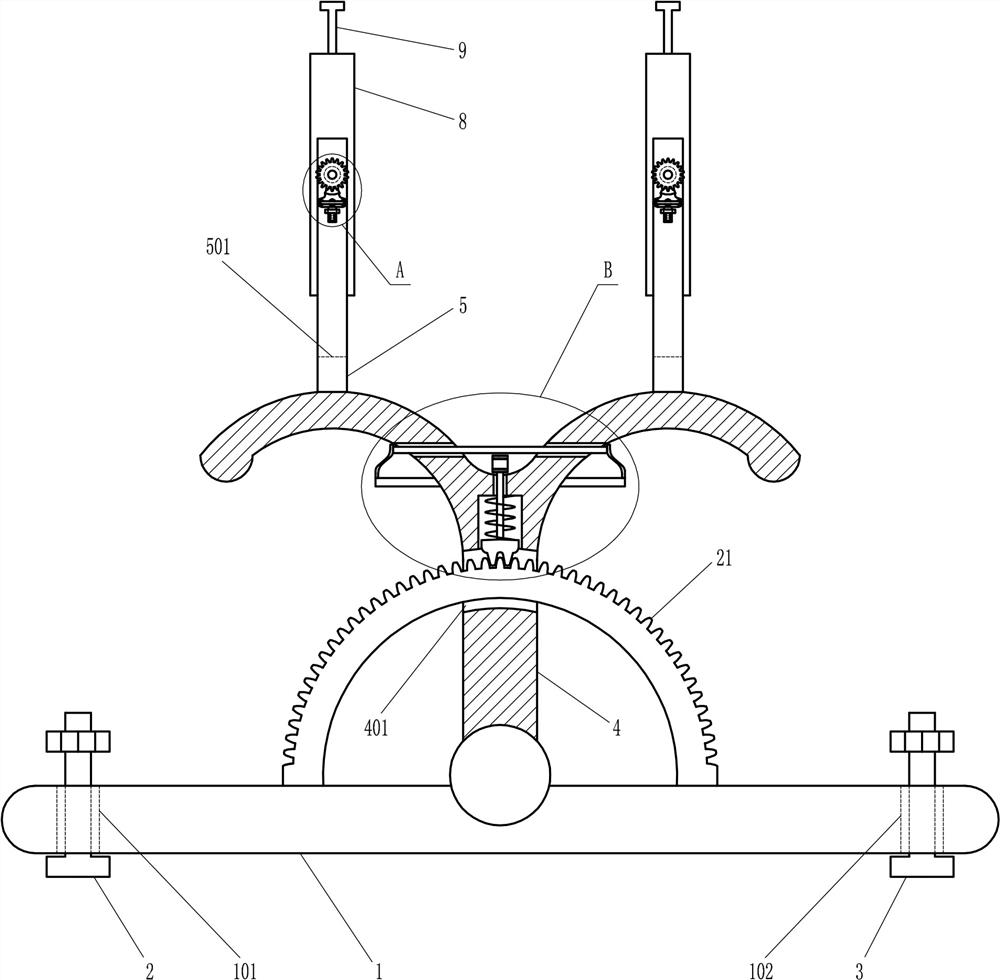

[0020] A multifunctional fixture for aluminum profile CNC machining centers, such as Figure 1-4 As shown, it includes the base 1, the first large bolt 2, the second large bolt 3, the large bracket 4, the large support plate 5, the large rotating shaft 6, the large bearing 7, the flip plate 8, the first long screw rod 9, and the pressure plate 10. The second long screw 11, pressing block 12, pinion 13, small latch 14, movable plate 15, U-shaped rod 16 and small spring 17, the left end of the base 1 has the first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is located in the second large through hole 102, the middle position of the top of the base 1 is hingedly connected with the lower end of the large bracket 4, and the large The middle part of support 4 has large arc groove 401, and the top of large support 4 has large groove 402, guide ho...

Embodiment 2

[0022] A multifunctional fixture for aluminum profile CNC machining centers, such as Figure 1-4As shown, it includes the base 1, the first large bolt 2, the second large bolt 3, the large bracket 4, the large support plate 5, the large rotating shaft 6, the large bearing 7, the flip plate 8, the first long screw rod 9, and the pressure plate 10. The second long screw 11, pressing block 12, pinion 13, small latch 14, movable plate 15, U-shaped rod 16 and small spring 17, the left end of the base 1 has the first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is located in the second large through hole 102, the middle position of the top of the base 1 is hingedly connected with the lower end of the large bracket 4, and the large The middle part of support 4 has large arc groove 401, and the top of large support 4 has large groove 402, guide hol...

Embodiment 3

[0025] A multifunctional fixture for aluminum profile CNC machining centers, such as Figure 1-4 As shown, it includes the base 1, the first large bolt 2, the second large bolt 3, the large bracket 4, the large support plate 5, the large rotating shaft 6, the large bearing 7, the flip plate 8, the first long screw rod 9, and the pressure plate 10. The second long screw 11, pressing block 12, pinion 13, small latch 14, movable plate 15, U-shaped rod 16 and small spring 17, the left end of the base 1 has the first large through hole 101, the first large bolt 2 is located in the first large through hole 101, the right end of the base 1 has a second large through hole 102, the second large bolt 3 is located in the second large through hole 102, the middle position of the top of the base 1 is hingedly connected with the lower end of the large bracket 4, and the large The middle part of support 4 has large arc groove 401, and the top of large support 4 has large groove 402, guide ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com