A fixture for clamping shaft-type workpieces for CNC milling machines

A CNC milling machine, shaft type technology, applied in the direction of manufacturing tools, metal processing mechanical parts, clamping and other directions, can solve the problems of affecting processing accuracy, axial shaking of shaft type workpieces, etc., to improve processing accuracy, save air, and improve clamping holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

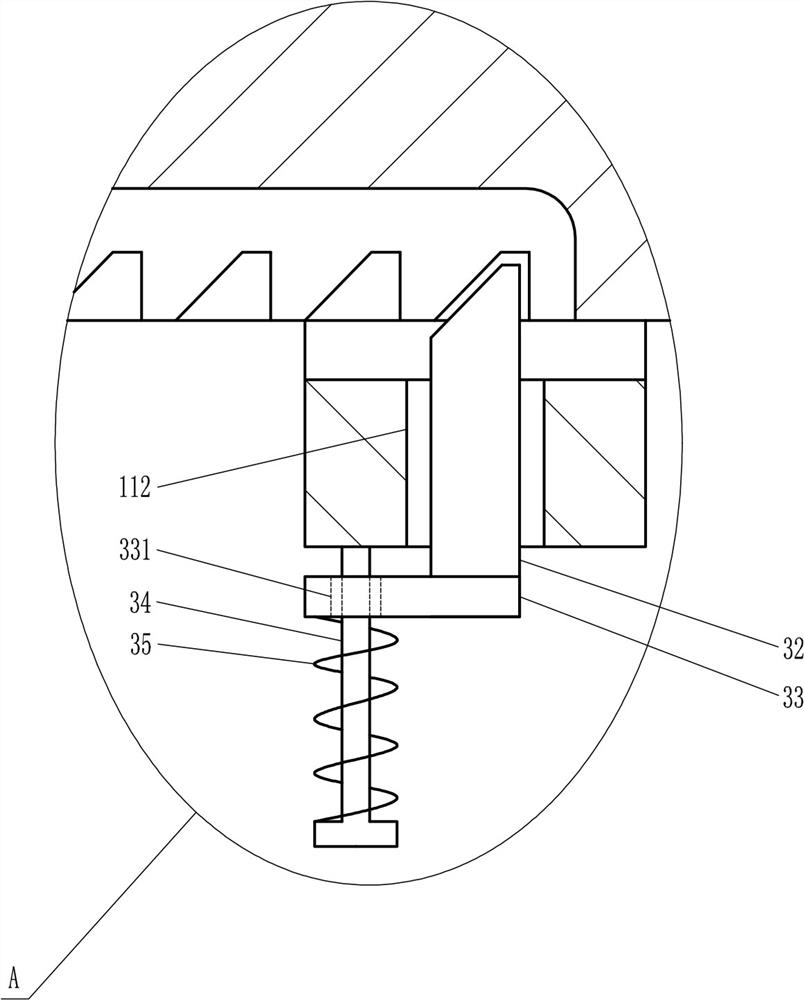

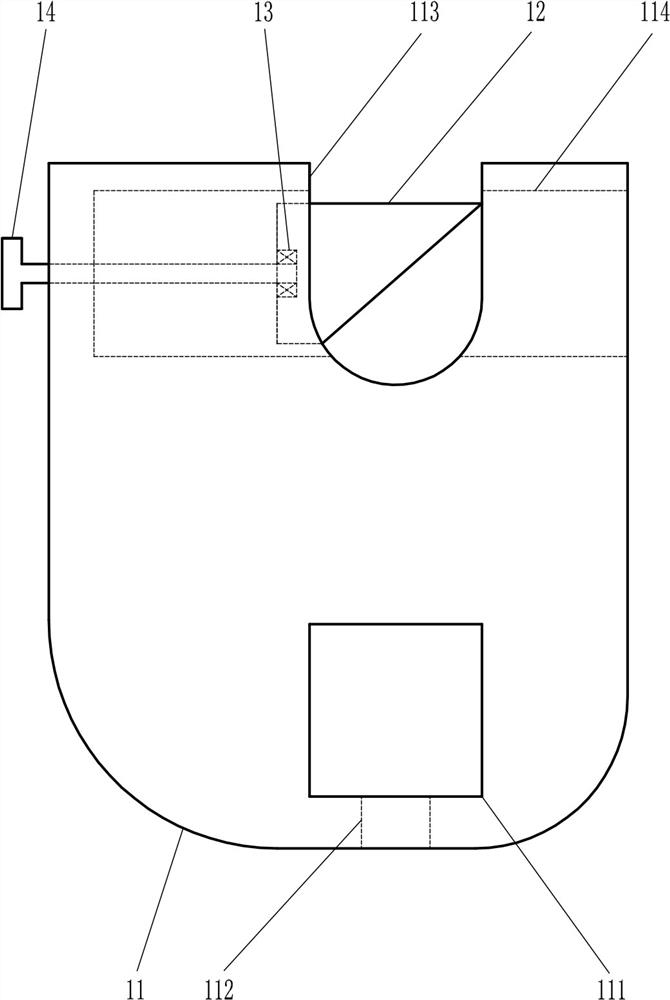

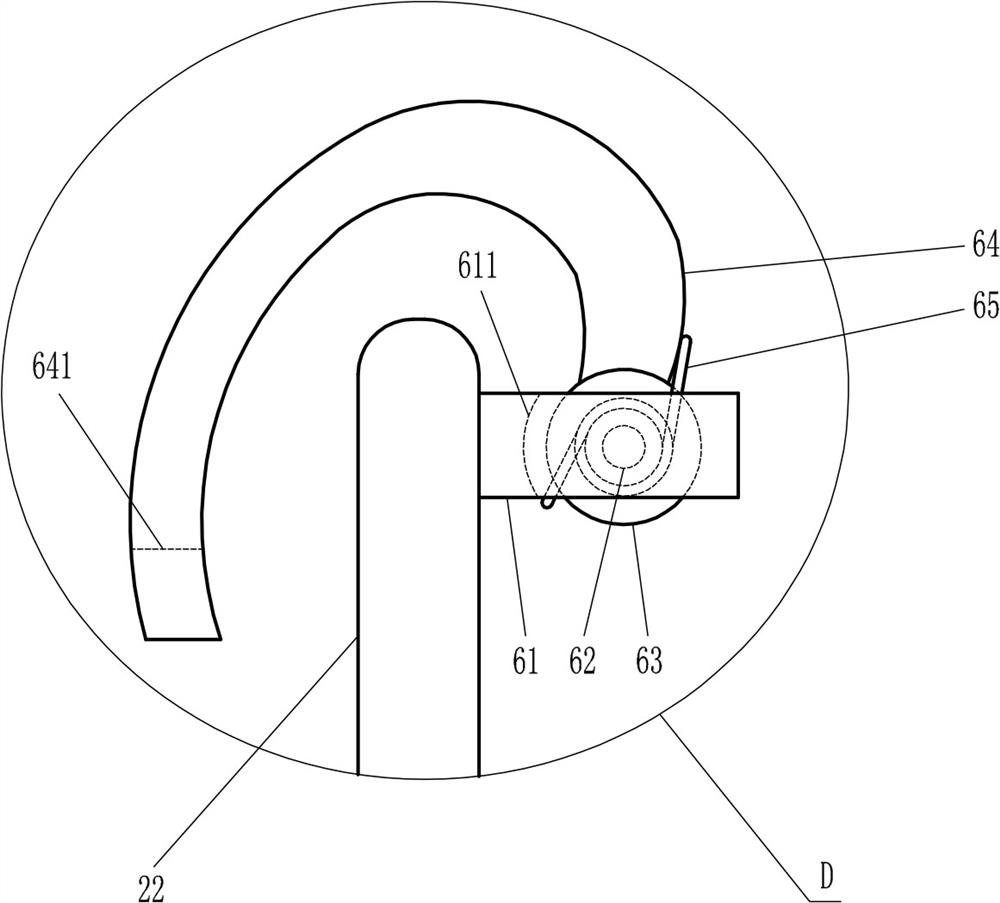

[0023] A fixture for a CNC milling machine to clamp a shaft-type workpiece, such as Figure 1-7 As shown, it includes a base 1, a large bolt 2, a large bracket 3, a rectangular guide rod 4, a large fixed plate 5, an arc-shaped guide plate 6, a ball 7, a small bracket 8, a large screw rod 9, a large tension spring 10, the first Large supporting plate 11, left wedge-shaped clamping plate 12, first bearing 13, first long screw rod 14, first connecting plate 15, first baffle plate 16, second large supporting plate 17, right wedge-shaped clamping plate 18, second bearing 19. The second long screw rod 20, the second connecting plate 21 and the second baffle plate 22. The base 1 has a large through hole 101 that penetrates up and down. The large bolt 2 is located in the large through hole 101 in a sliding manner. The top of the base 1 is connected with a large Support 3, the upper end of large support 3 is hingedly connected with the bottom of rectangular guide bar 4, and the right s...

Embodiment 2

[0025] A fixture for a CNC milling machine to clamp a shaft-type workpiece, such as Figure 1-7 As shown, it includes a base 1, a large bolt 2, a large bracket 3, a rectangular guide rod 4, a large fixed plate 5, an arc-shaped guide plate 6, a ball 7, a small bracket 8, a large screw rod 9, a large tension spring 10, the first Large supporting plate 11, left wedge-shaped clamping plate 12, first bearing 13, first long screw rod 14, first connecting plate 15, first baffle plate 16, second large supporting plate 17, right wedge-shaped clamping plate 18, second bearing 19. The second long screw rod 20, the second connecting plate 21 and the second baffle plate 22. The base 1 has a large through hole 101 that penetrates up and down. The large bolt 2 is located in the large through hole 101 in a sliding manner. The top of the base 1 is connected with a large Support 3, the upper end of large support 3 is hingedly connected with the bottom of rectangular guide bar 4, and the right s...

Embodiment 3

[0028] A fixture for a CNC milling machine to clamp a shaft-type workpiece, such as Figure 1-7As shown, it includes a base 1, a large bolt 2, a large bracket 3, a rectangular guide rod 4, a large fixed plate 5, an arc-shaped guide plate 6, a ball 7, a small bracket 8, a large screw rod 9, a large tension spring 10, the first Large supporting plate 11, left wedge-shaped clamping plate 12, first bearing 13, first long screw rod 14, first connecting plate 15, first baffle plate 16, second large supporting plate 17, right wedge-shaped clamping plate 18, second bearing 19. The second long screw rod 20, the second connecting plate 21 and the second baffle plate 22. The base 1 has a large through hole 101 that penetrates up and down. The large bolt 2 is located in the large through hole 101 in a sliding manner. The top of the base 1 is connected with a large Support 3, the upper end of large support 3 is hingedly connected with the bottom of rectangular guide bar 4, and the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com