Welding method for tube sheet of robot based on laser three-dimensional modeling

A laser three-dimensional, tube-sheet welding technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as failure to meet user requirements, poor consistency of heat dissipation pipes, and welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

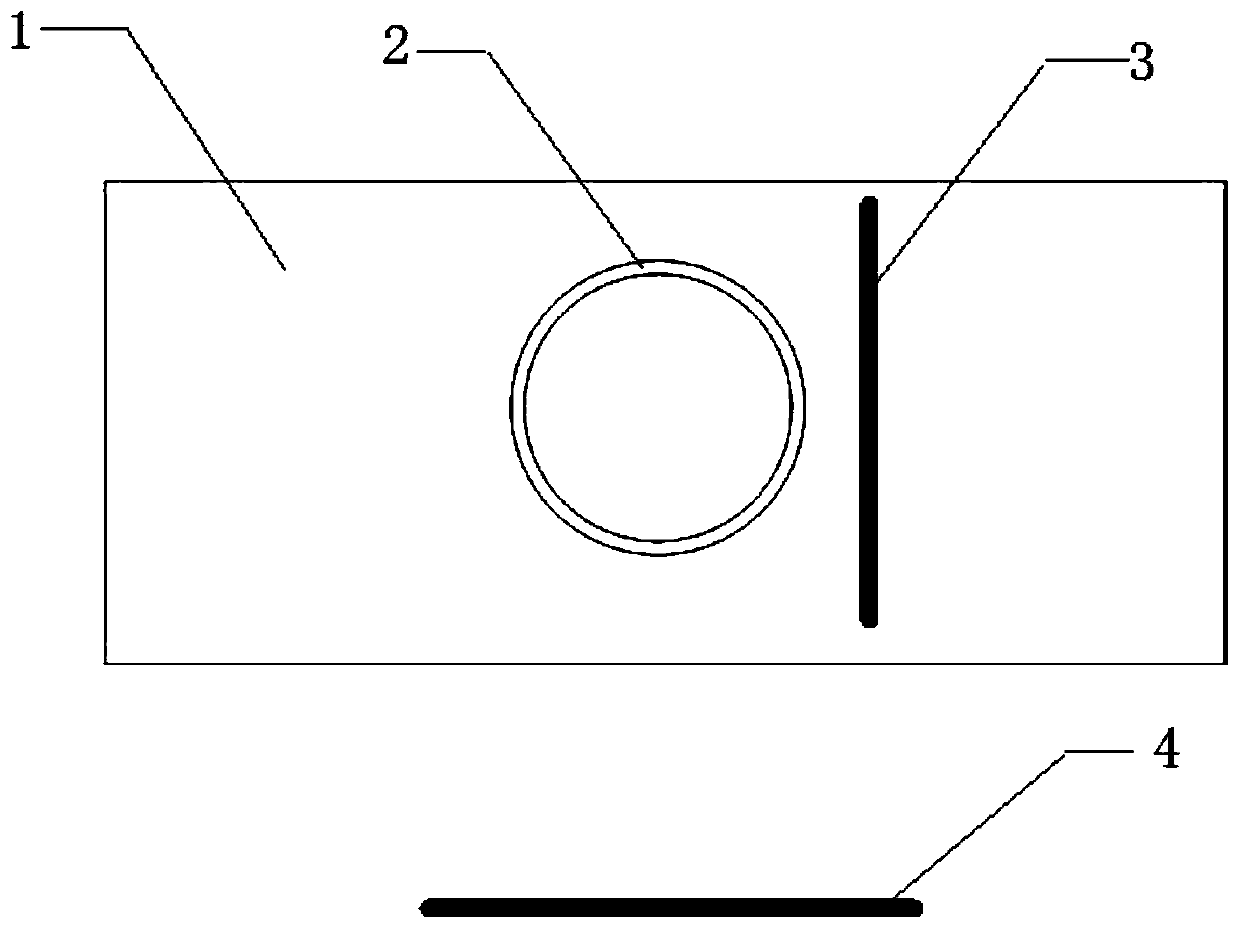

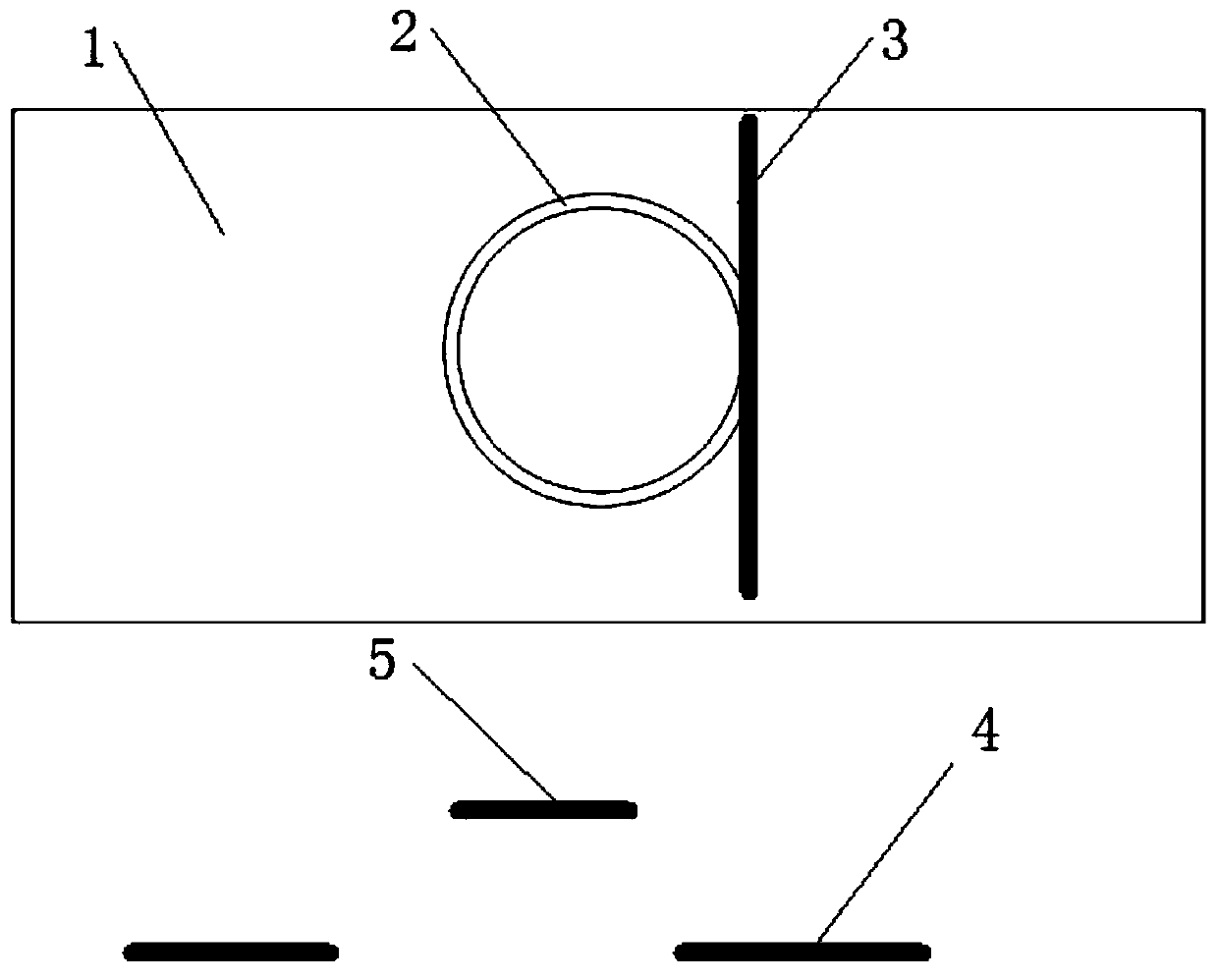

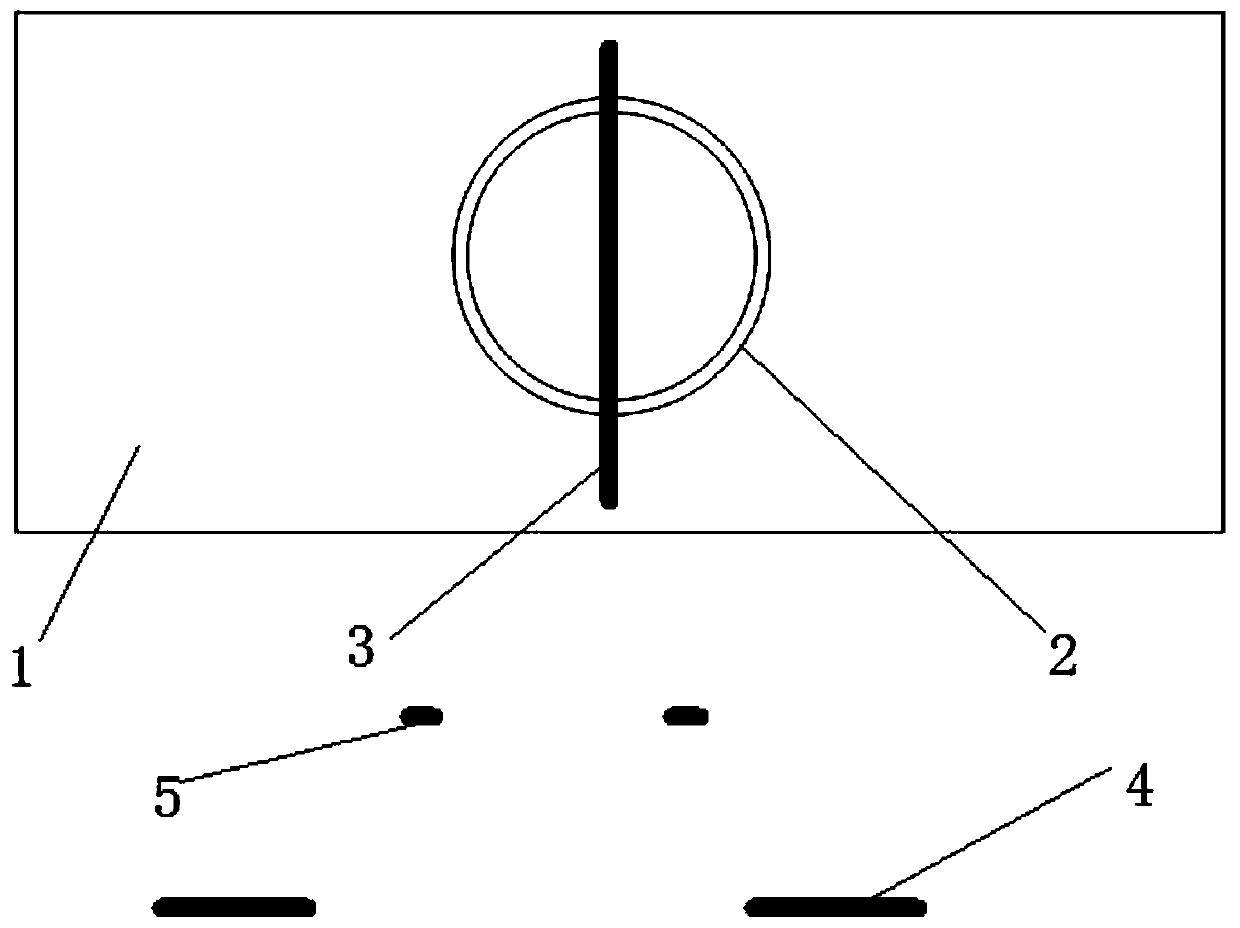

[0024] The tube plate to be welded in the present invention includes a base plate 1 and a heat dissipation pipe 2, the base plate has a through hole, and the heat dissipation pipe 2 is inserted into the through hole. During welding, it is necessary to weld the edge of the through hole on the upper surface of the substrate 1 with the heat dissipation pipe 2 .

[0025] The present invention comprises the following steps:

[0026] Step A. Three-dimensional imaging of the tube sheet to be welded.

[0027] First fix the tube sheet on the workbench, then use the laser probe fixed on the welding robot to scan the set area on the tube sheet row by row or column by row and sample the scanned image, and combine the current coordinate position of the welding ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap