Quantitative feeding device

A cutting and filling technology, which is applied to supply devices, manufacturing tools, etc., can solve the problems of excessive cutting volume, incompleteness, and complex container structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

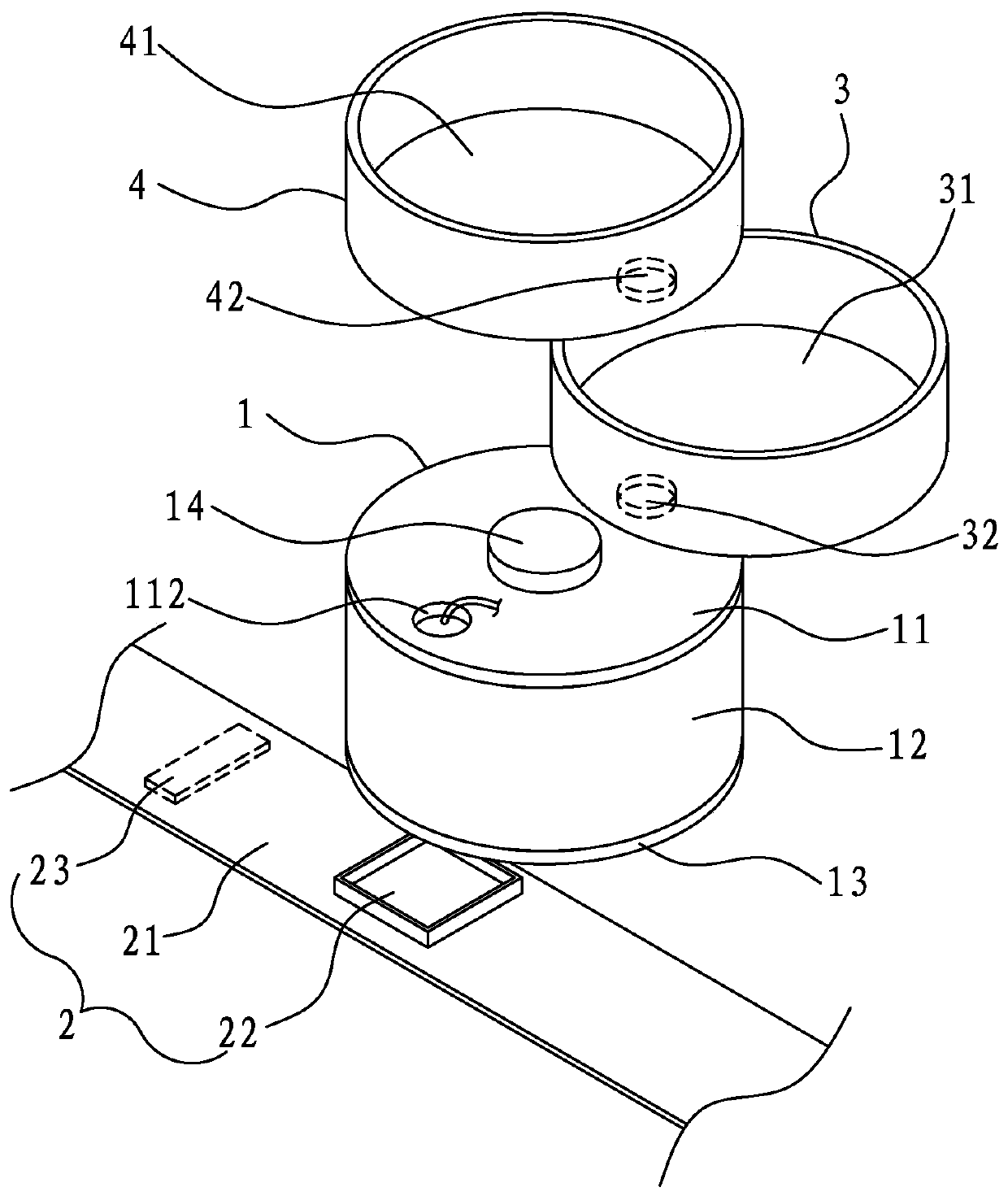

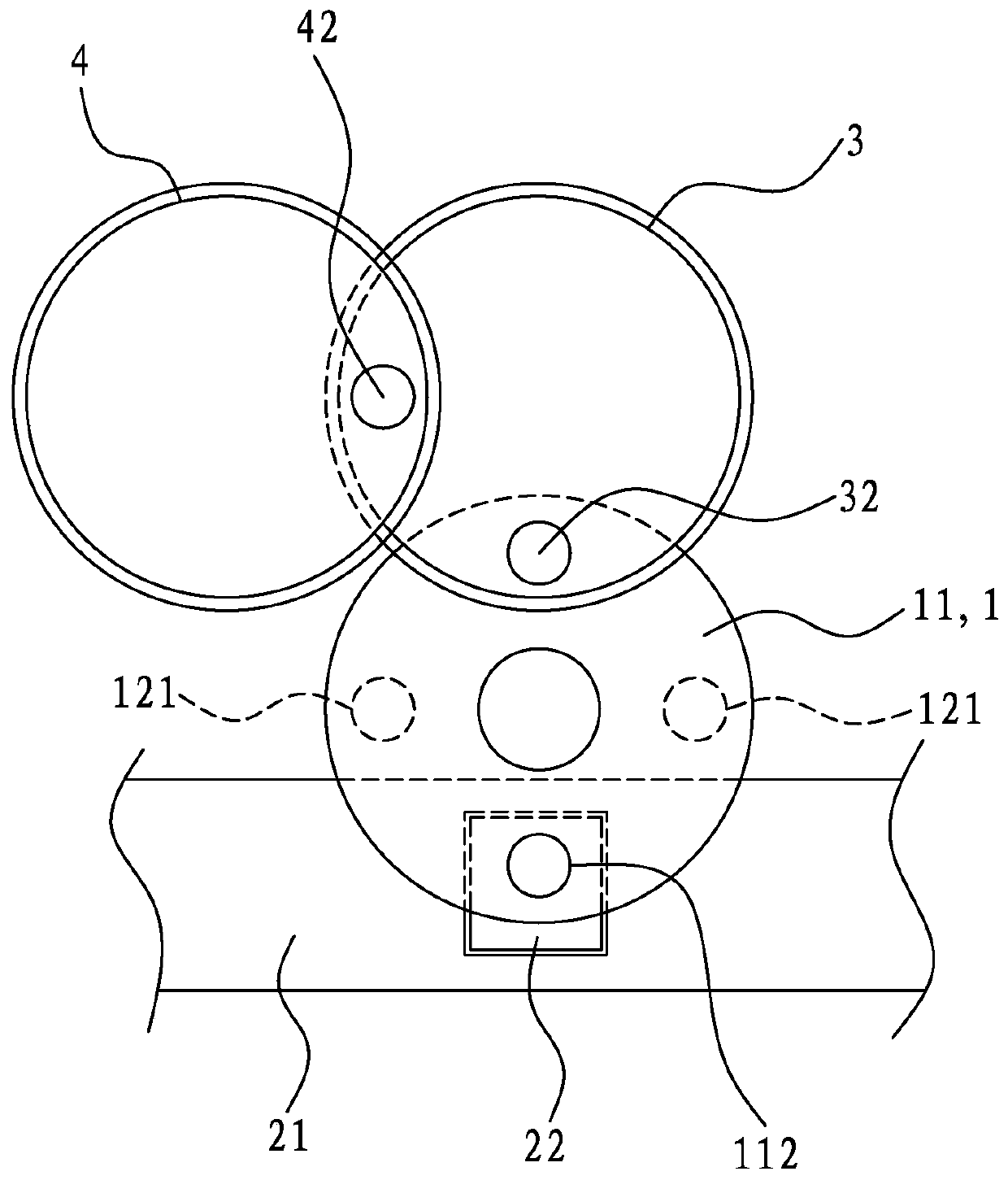

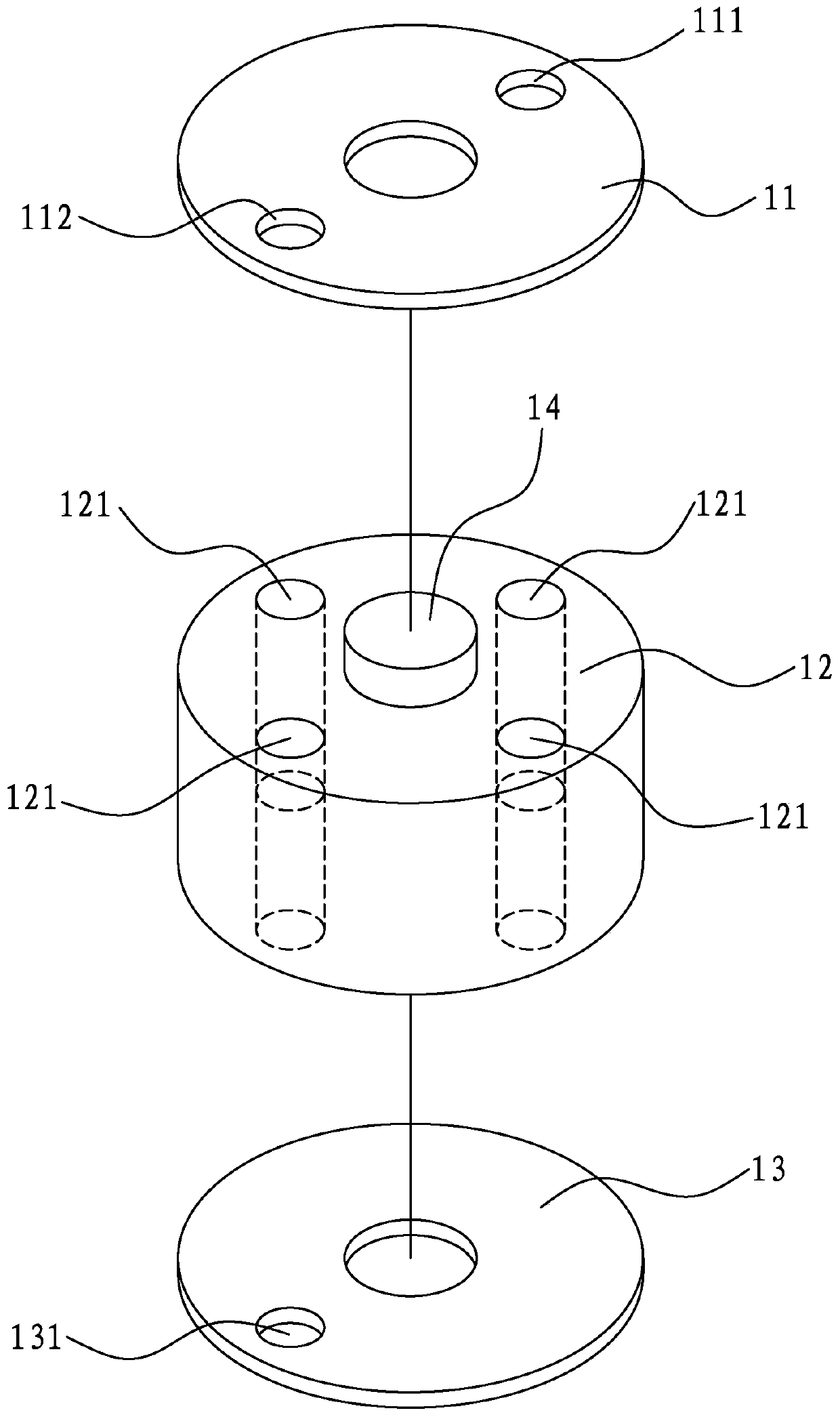

[0032] see figure 1 , figure 2 and image 3 , the present invention discloses a quantitative feeding device, which includes a material injection mechanism 1 and a material conveying mechanism 2 located below the material injection mechanism 1; the material injection mechanism 1 has an upper plate body 11, a turntable 12 and a lower plate Body 13, the turntable 12 is pivotally connected between the upper plate body 11 and the lower plate body 13 through the rotating shaft 14; the turntable 12 is provided with a plurality of injection chambers 121 that penetrate up and down, and the upper plate body 11 is set There is a feeding port 111 communicating with any one of the injection chambers 121, and the lower plate body 13 is provided with a feeding port 131 communicating with any one of the injection chambers 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com