Automatic glove production and impregnation control mechanism

A control mechanism and glove technology, applied in coatings, household appliances, household components, etc., can solve the problems of affecting the quality of dipping, difficult maintenance, inconvenient disassembly, etc., to meet the requirements of dipping quality, ensure accurate control, and avoid shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

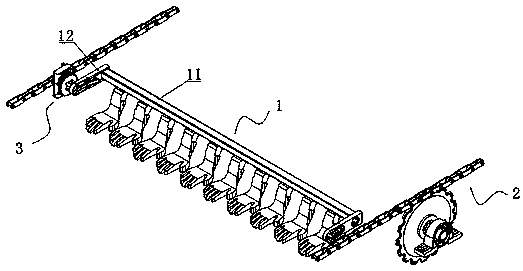

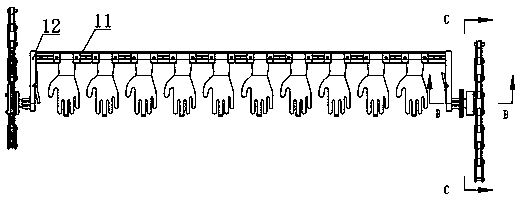

[0057] Such as figure 1 As shown, the glove automatic production dipping clutch control mechanism of the present invention includes

[0058] Several die rods 1 are used to install a plurality of hand molds 11 that can be fitted with gloves to be dipped in rubber. Die rod supports 12 are arranged at both ends of the die rods 1 .

[0059] The mold rod conveying device 2 is used to drive each mold rod to pass through a station that can dip gloves in turn; The sprocket drives the movement, and the output sprocket is directly or indirectly connected to the drive motor.

[0060] The rotation phase control mechanism 3 is arranged between the end of the mold bar 1 and the mold bar conveying device 2 , and is used to realize connection locking or relative rotation between the mold bar 1 and the mold bar conveying device 2 .

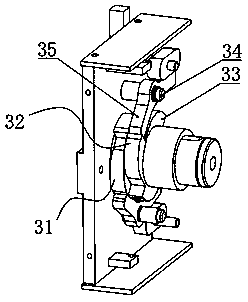

[0061] Such as image 3 As shown, the rotation phase control mechanism 3 has a first ratchet mechanism 31 and a second ratchet mechanism 32, the first ratchet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com