Automatic water draining structure for track vehicle floor

An automatic drainage and rail vehicle technology, applied in drainage structures, railway car bodies, water supply devices, etc., can solve problems such as water accumulation, improve sanitary conditions, prevent flooding accidents, and reduce the workload of artificial drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

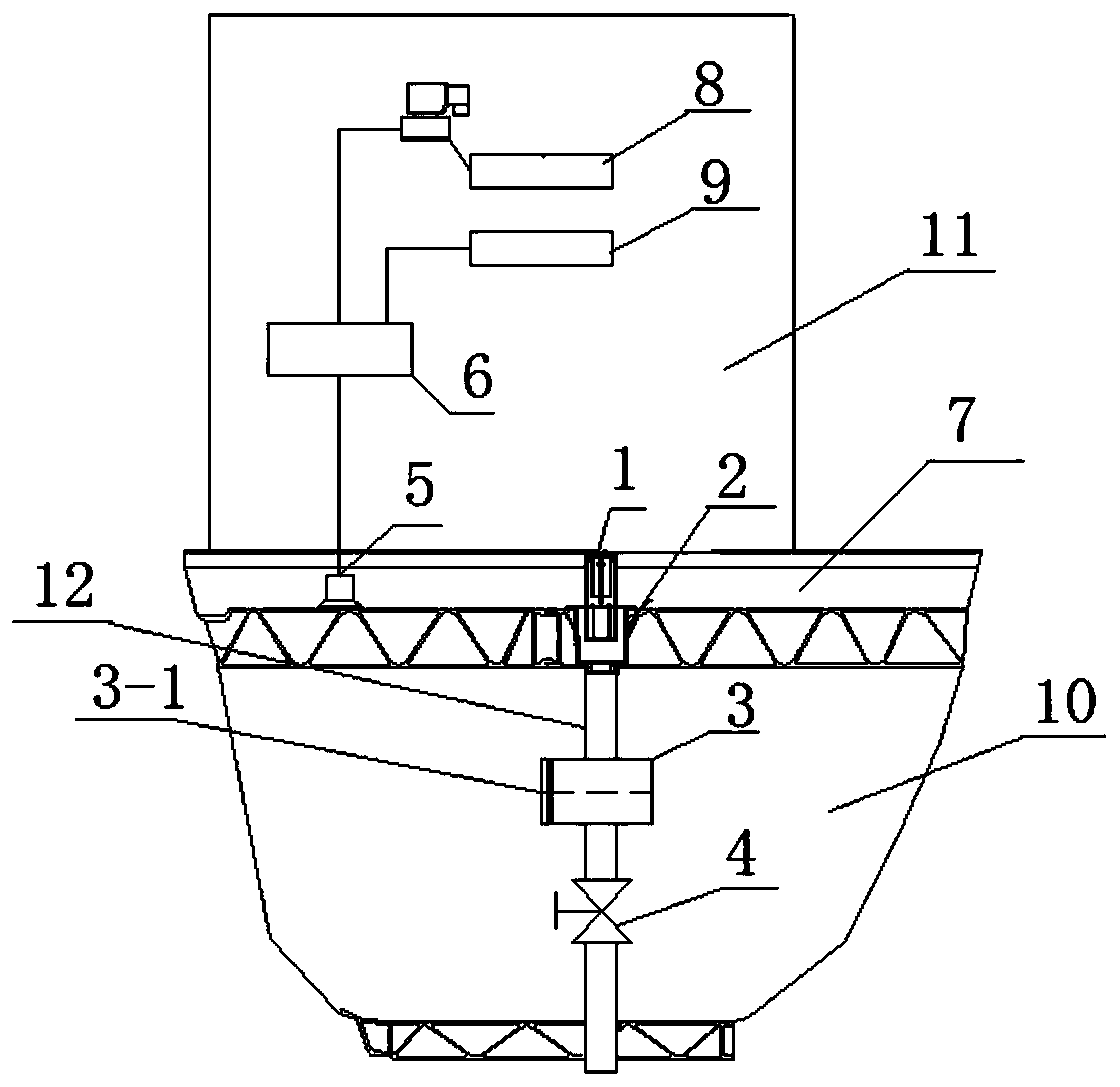

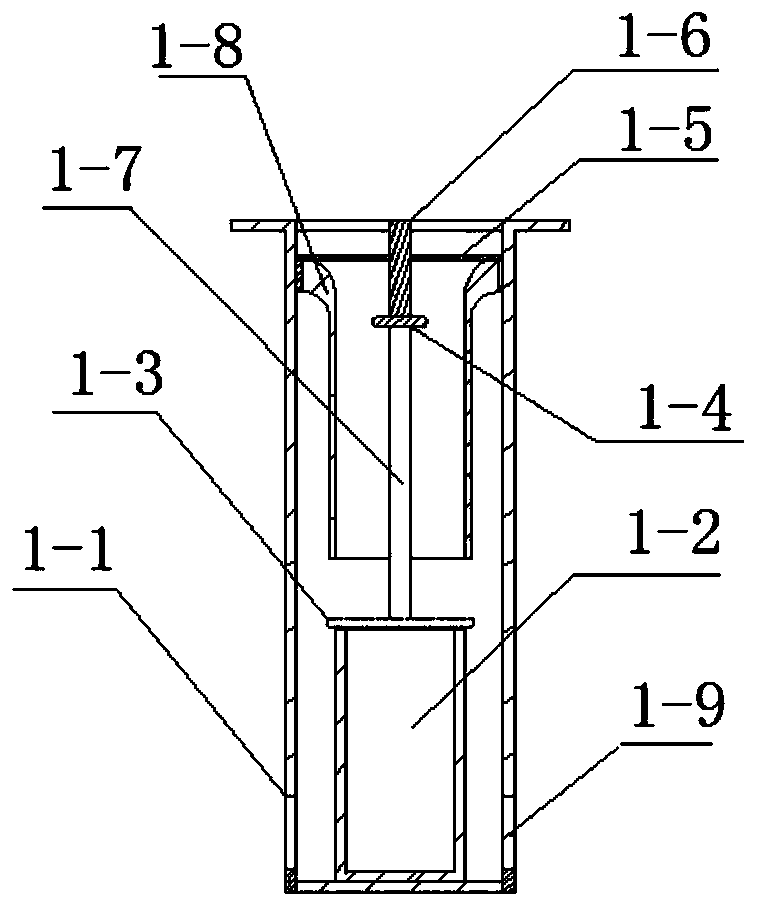

[0016] refer to figure 1 , figure 2 , the specific embodiment of the present invention is that in the bathroom, the kitchen 11, the vehicle floor interlayer 7 is provided with a drain seat 2, and the bottom of the drain seat is provided with a drain hole, and the drain hole is connected to the drain line 12, and the drain line is placed in the equipment compartment 10. Inside, a liquid level sensor 5 is installed in the interlayer of the floor, and an electric ball valve 4 is installed at the end of the drainage pipeline. The liquid level sensor 5 is connected to the control unit 6, and the control unit is connected to the speed sensor 9 on the vehicle and the water inlet solenoid valve 8; the bathroom and the upper floor of the kitchen The floor is perforated, and a floating floor drain 1 is set through the hole, and the bottom of the floating floor drain stretches into the drain tank seat 2, which is used for toilet and kitchen floor drainage and floor interlayer drain tank...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap