A coal mine fault waterproof structure

A technology of faults and coal mines, applied in the field of coal mining, can solve problems such as fault collapse, achieve the effects of preventing water penetration, improving integrity, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

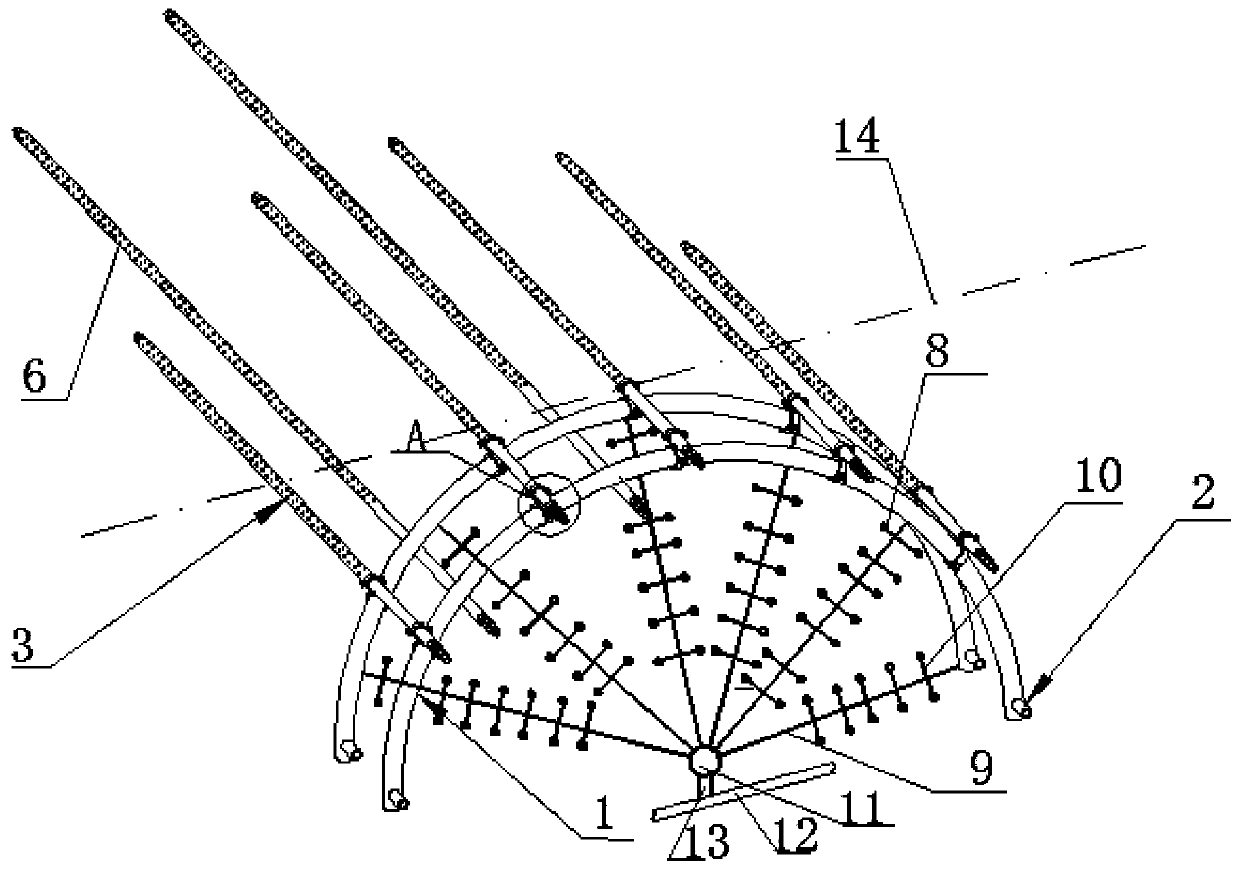

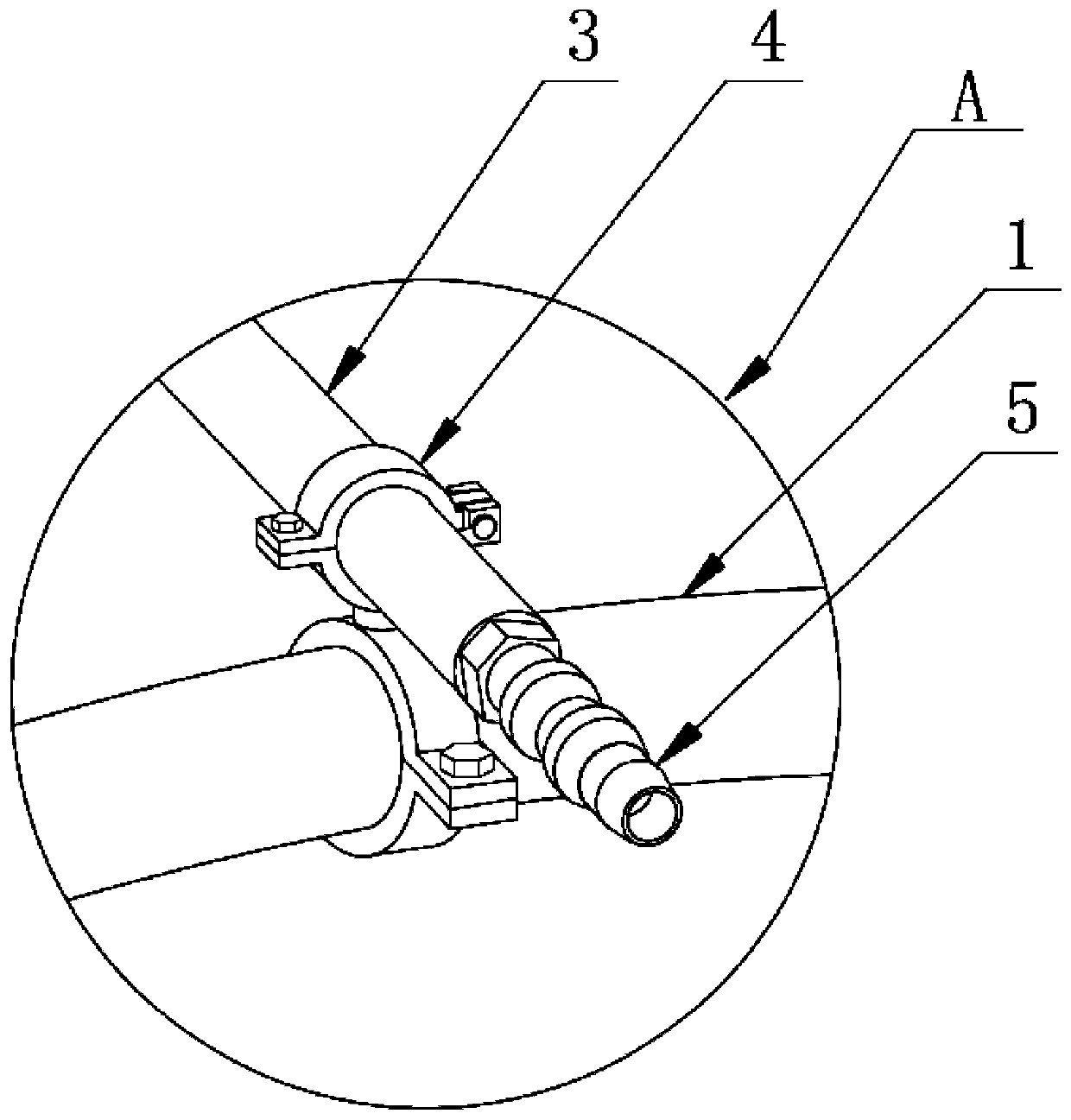

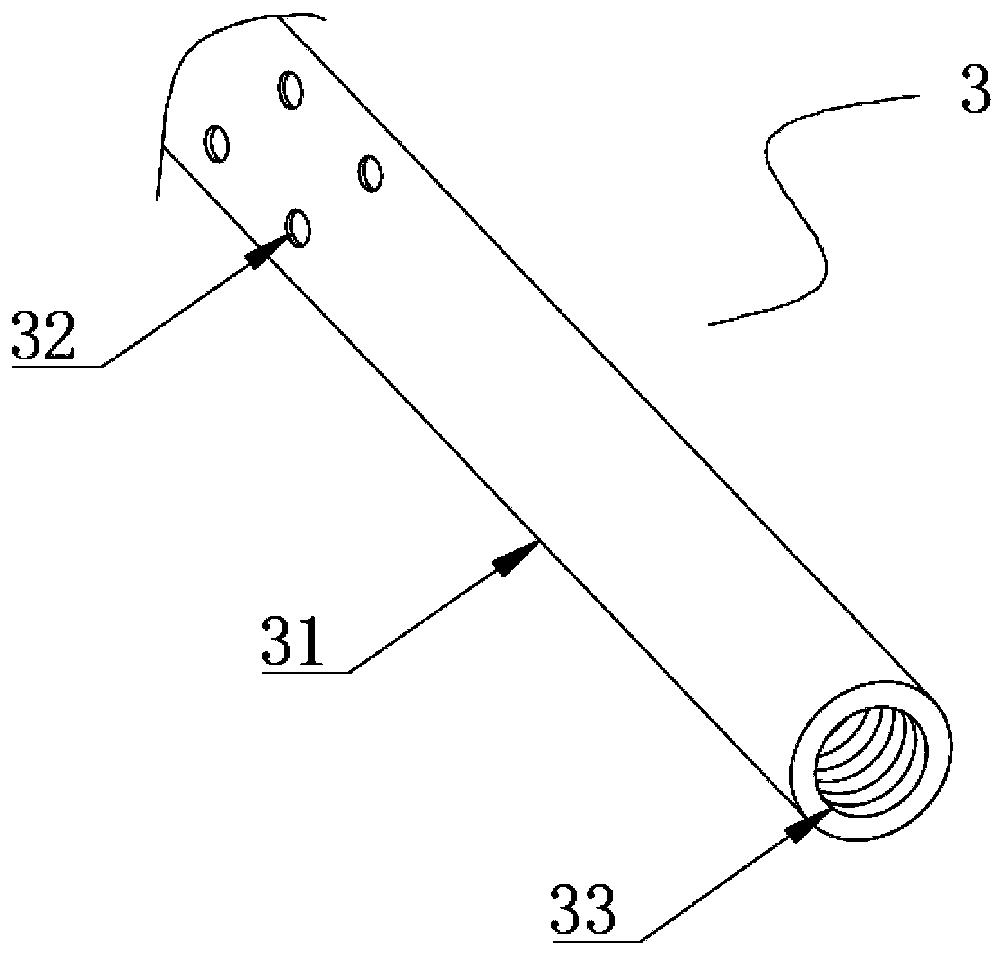

[0024] see Figure 1~6 , in an embodiment of the present invention, a coal mine fault waterproof structure, including a steel pipe arch column 1, a plurality of radially tensioned main bars 9, branch steel bars 10, a tensioned base assembly, a grouting anchor pipe assembly and a suction pipe assembly 6, Among them, two groups of steel pipe arch columns 1 arranged parallel to each other close to the roadway wall 16 are fixed at the position of the roadway wall at the fault position of the coal mine, and the steel pipe arch columns 1 are connected with drill holes extending into the roadway wall 16 A plurality of grouting anchor pipe assemblies and a plurality of suction pipe assemblies inside, the detachable connection of the outer ends of the grouting anchor pipe assembly and the suction pipe assembly is provided with a suction joint assembly and a grouting joint assembly 15, the The depth of the inner end of the suction pipe assembly is greater than the depth of the inner end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap