Vertical mill rotary airlock valve with good damping effect

An air-locking feeder and shock-absorbing technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of time-consuming and laborious manual cleaning, delaying the feeding process, blockage, etc., to reduce the difficulty of cleaning and achieve a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

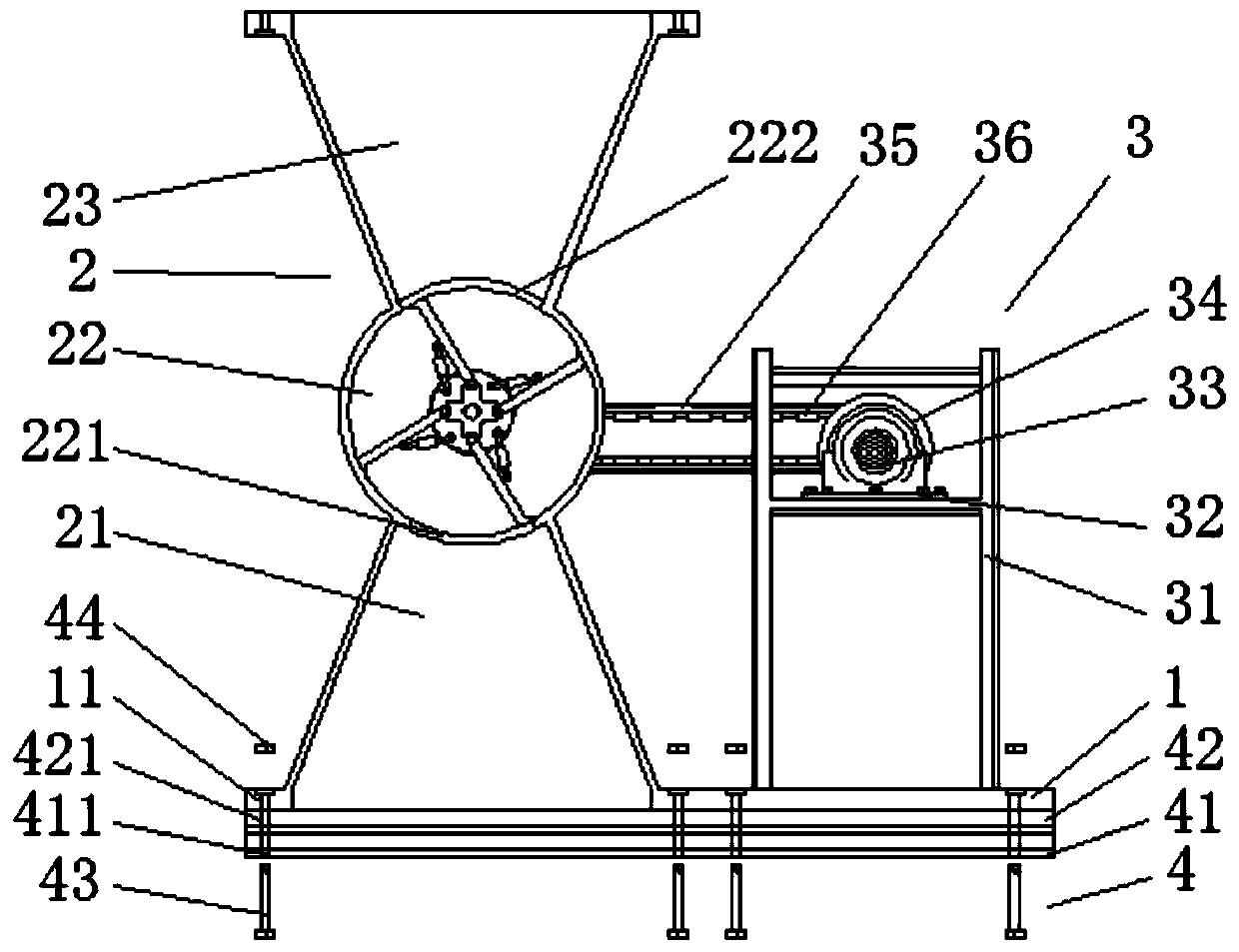

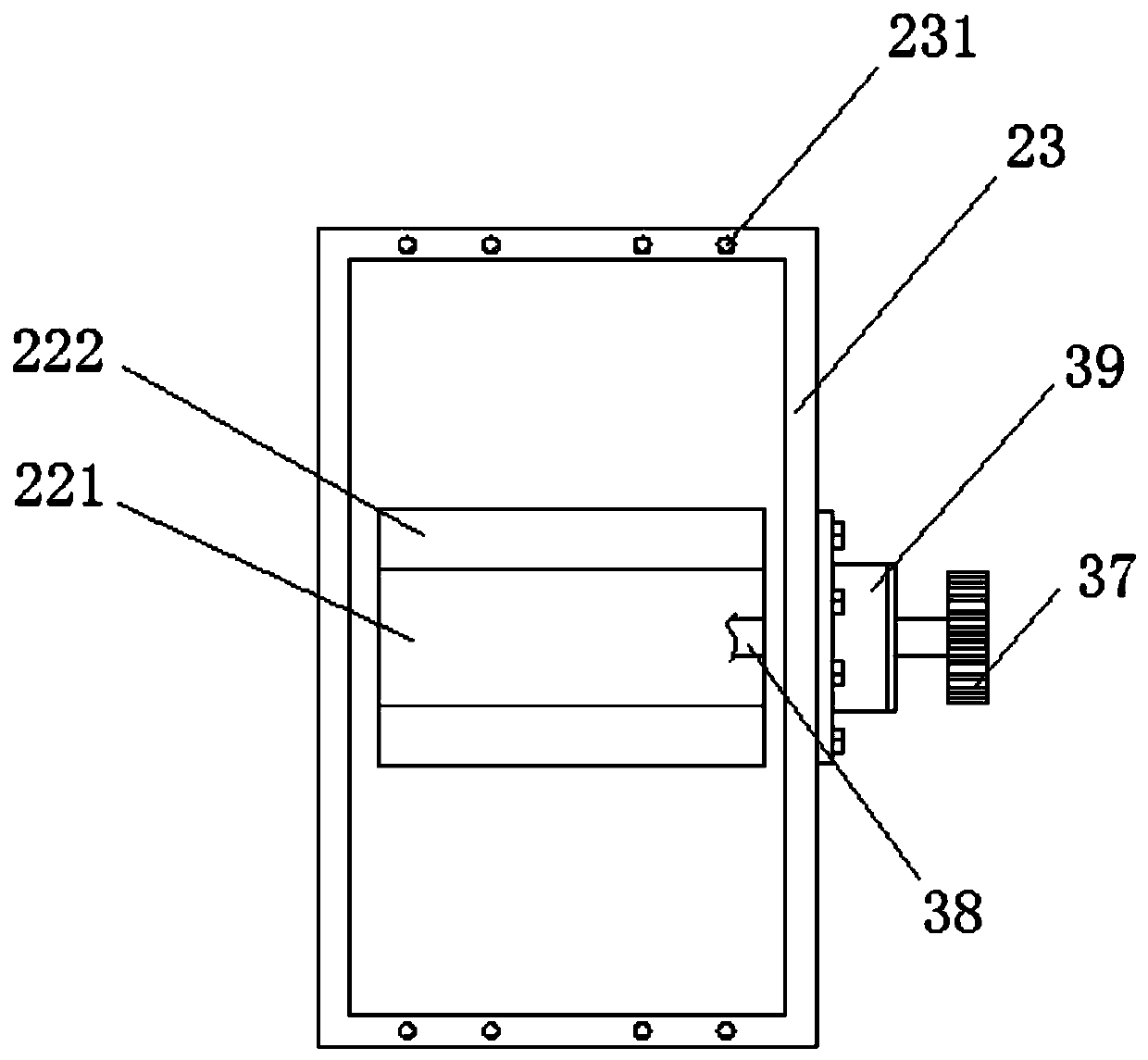

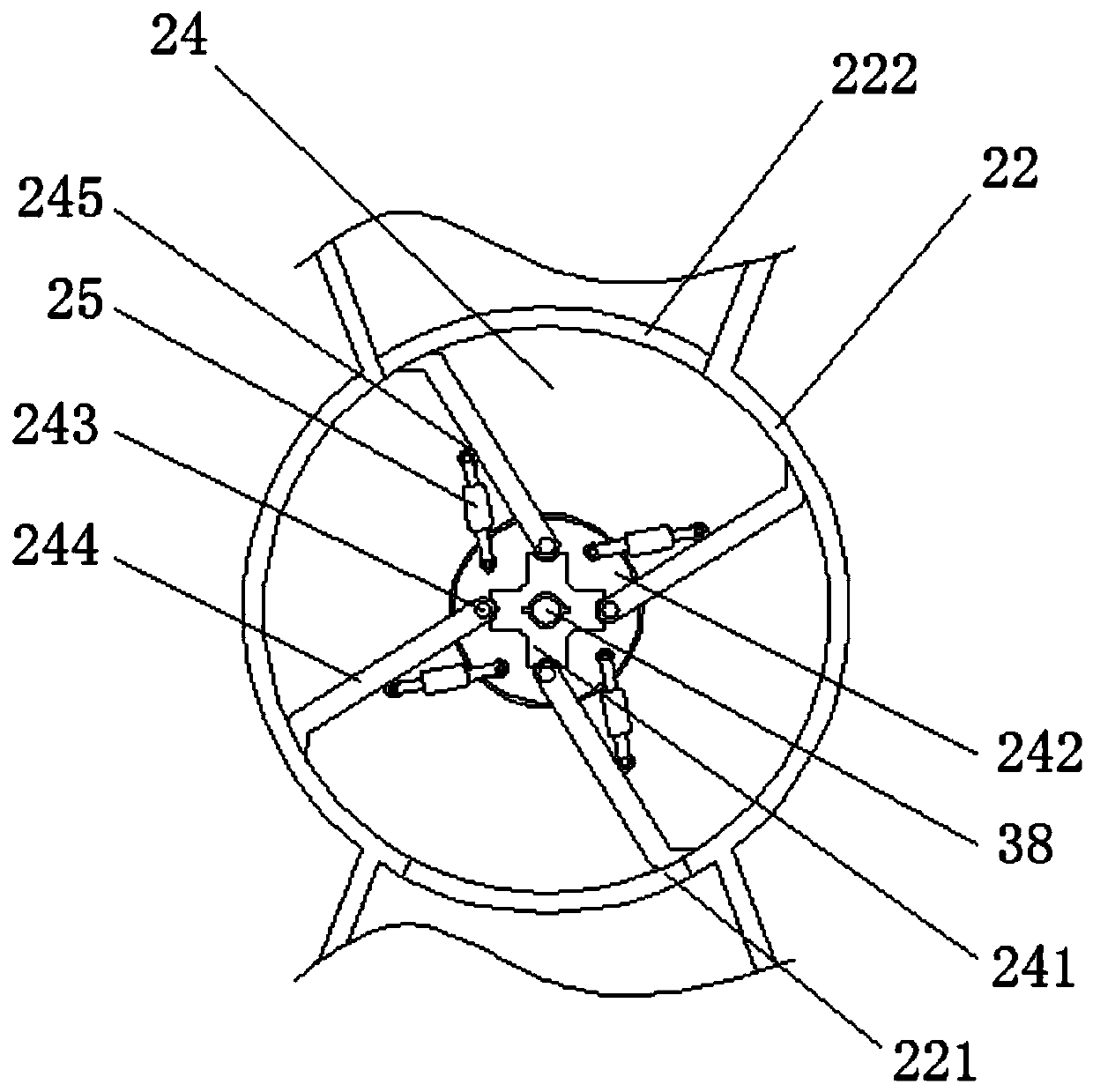

[0023] Example: such as Figure 1-6 As shown, a vertical mill rotary air lock feeder with good damping effect in the present invention includes a base plate 1, a feeding mechanism 2, a driving mechanism 3 and a shock absorbing mechanism 4, and the upper side of the base plate 1 is provided with a feeding mechanism 2 And driving mechanism 3, the underside of base plate 1 is provided with damping mechanism 4, and base plate 1 is provided with some mounting holes 11, and damping mechanism 4 comprises rubber pad 41, steel plate 42, screw rod 43 and nut 44, some rubber pads 41 and Several steel plates 42 are arranged at intervals in turn, rubber pad 41 is provided with some No. 1 perforations 411, steel plate 42 is provided with some No. 2 perforations 421, and mounting hole 11 is provided with screw rod 43, and one end of screw rod 43 passes through No. 1 perforation 411 and No. 2 perforation 421 is threadedly connected with nut 44. The feeding mechanism 2 includes a blanking cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com