Confluence gating device

A gating and converging fluid technology, applied in multi-way valves, engine components, mechanical equipment, etc., can solve the problems of liquid flow passage leakage, plastic aging, and the flatness of the contact surface cannot be well guaranteed. To achieve the effect of reliable end face sealing, ensuring flatness and reliable sealing connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

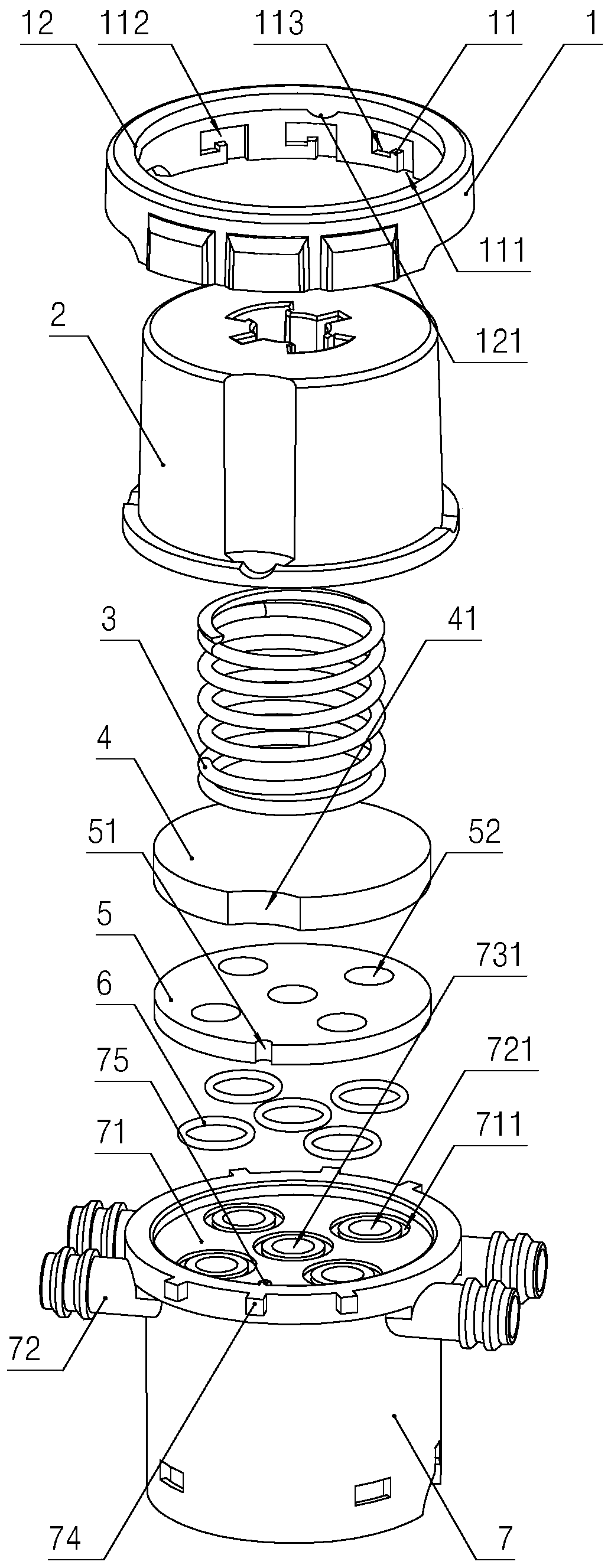

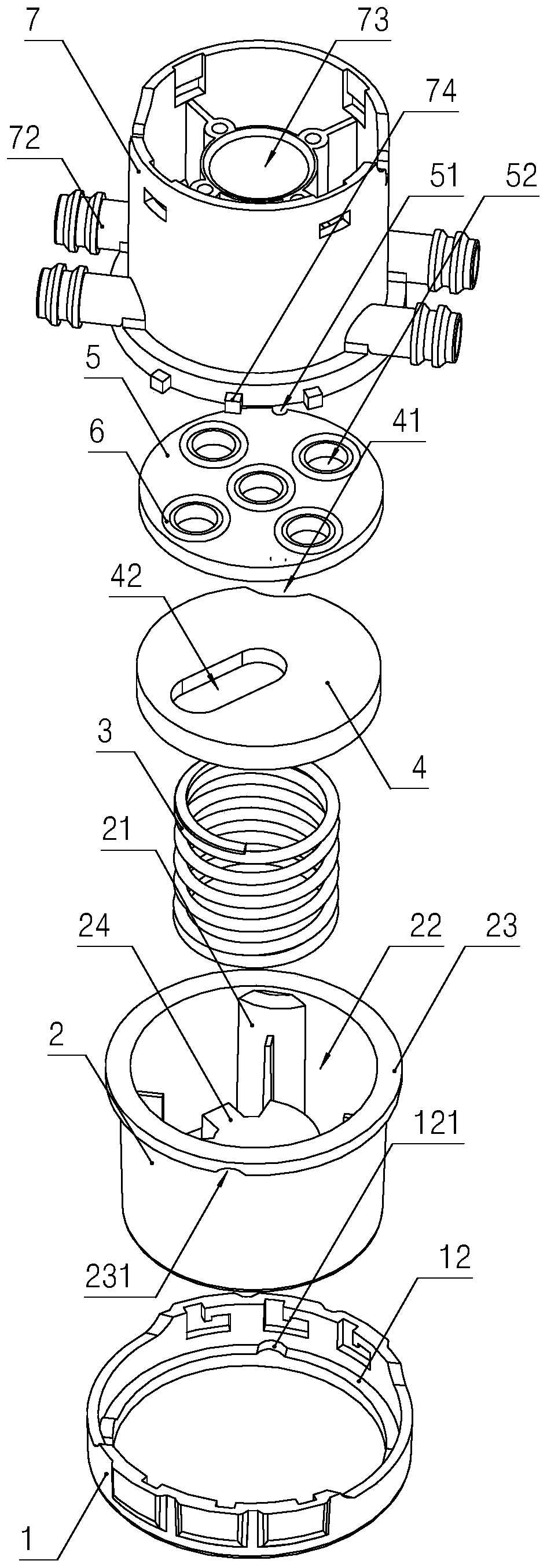

[0017] Attached below Figures 1 to 2 , which describes in detail a specific implementation of a bus gate in the present invention.

[0018] like figure 1 and figure 2 As shown, the confluence gating device of the present invention includes: a confluence body 7, a disk-shaped sealed static plate 5 and a sealed moving plate 4, and a liquid flow selection cover 2 matched with the sealed moving plate 4 and as an elastic The pressing spring 3 of the pressing part, the said confluence body 7 is provided with a liquid outlet channel 73 and four liquid inlet channels communicated one by one with the corresponding liquid inlet pipe 72 (belonging to the common technology in the art, Fig. not shown in), the said confluence body 7 is provided with a static disc installation chamber 71 matching with the said sealed static disc 5, and the bottom wall of the static disc installation chamber 71 is provided with a liquid outlet channel The liquid outlet 731 communicated with 73 and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com