A phase change heat extraction system

A thermal system and phase change technology, applied in lighting and heating equipment, cooling/heating devices for lighting devices, refrigerators, etc. Power supply damage and other problems, to ensure the heat dissipation performance, good heat dissipation effect, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

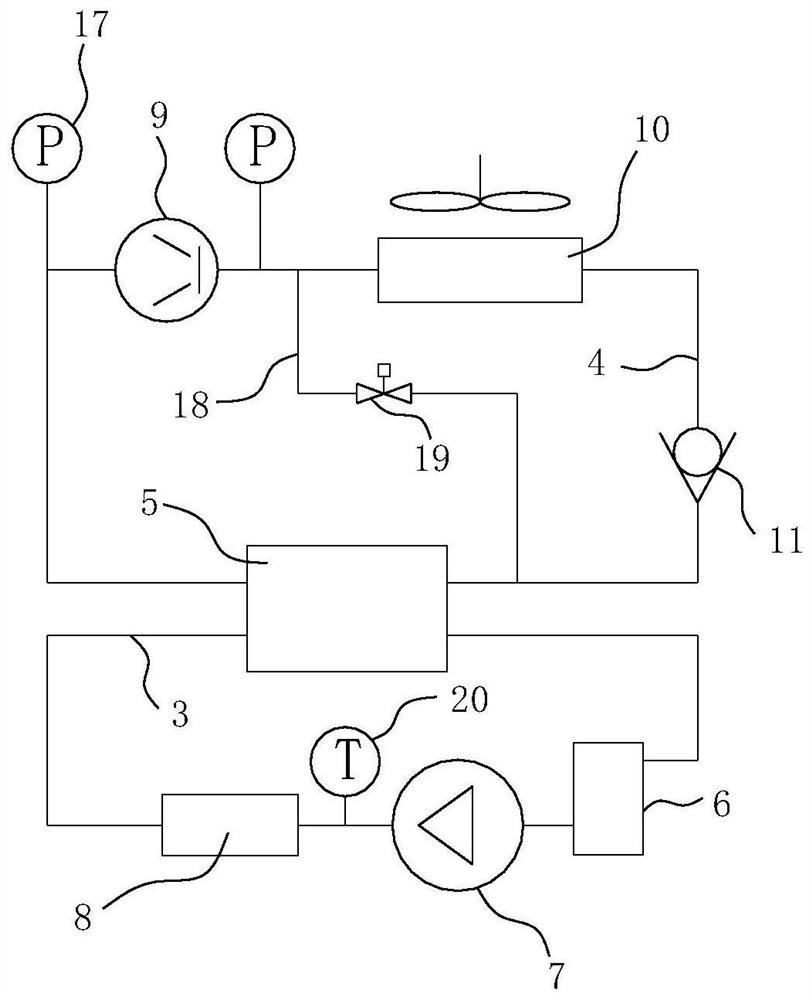

[0025] combine Figure 1-2 A phase-change heat extraction system shown includes a phase-change heat extraction circuit 3 for circulating phase-change medium and an active refrigeration circuit 4 for refrigerant circulation, and the phase-change heat extraction circuit 3 and active refrigeration circuit 4 meet In the same heat exchanger 5, and the phase change medium and the refrigerant perform heat exchange in the heat exchanger 5. In other words, there are two paths on the heat exchanger, one of which is connected to the phase change heat extraction circuit 3, and the other path is connected to the active refrigeration circuit 4, and the refrigerant in the active refrigeration circuit 4 is in the heat exchanger 5. The evaporated phase-change medium is refrigerated to recondense to a liquid state. The heat exchanger 5 can be a plate heat exchanger, a casing heat exchanger or the like.

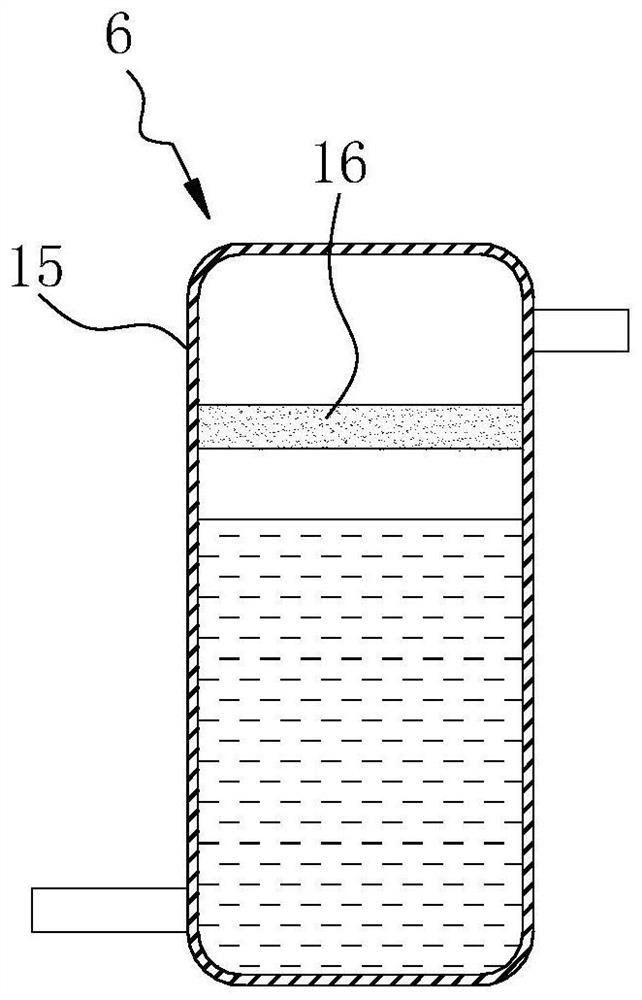

[0026] The phase change heat extraction circuit 3 is provided with a liquid storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com