Cable insulation layer sample cutting device and method

A technology of cable insulation and cutting device, which is applied in the direction of cable installation device, sampling device, cable installation, etc. It can solve the problems of cable insulation sheet width limitation and inability to test cable electrical performance, so as to improve the safety of power grid and have a good application prospect , Improve the effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

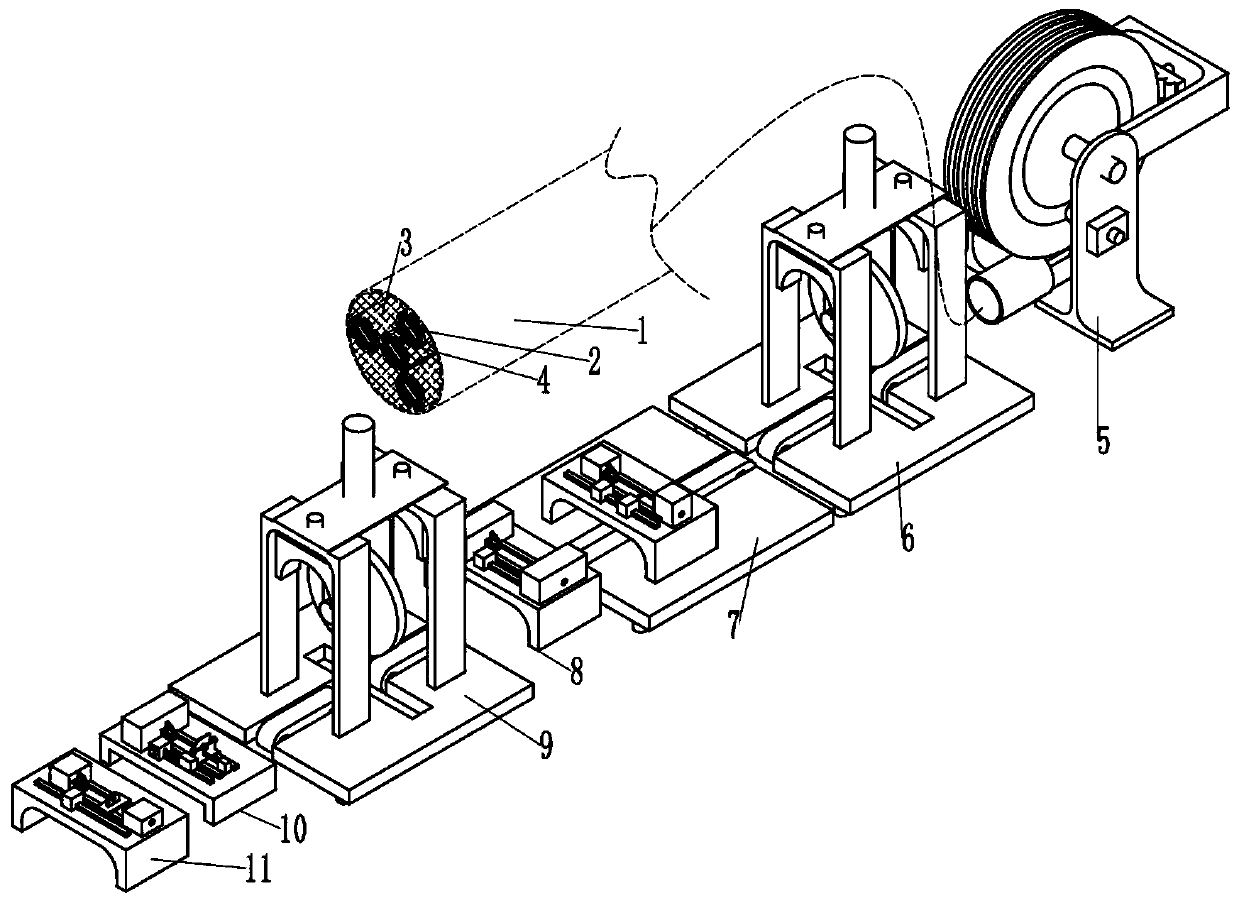

[0037] Such as Figure 1-7 , the existing cable includes several copper cores (2), an insulating layer (4) covering the copper cores (2), an armor layer (1) covering all the copper cores (2), and an armor layer Filling layer (3) between (1) and copper core (2). The invention realizes the automatic stripping of the existing cables, thereby obtaining an insulating layer with uniform thickness.

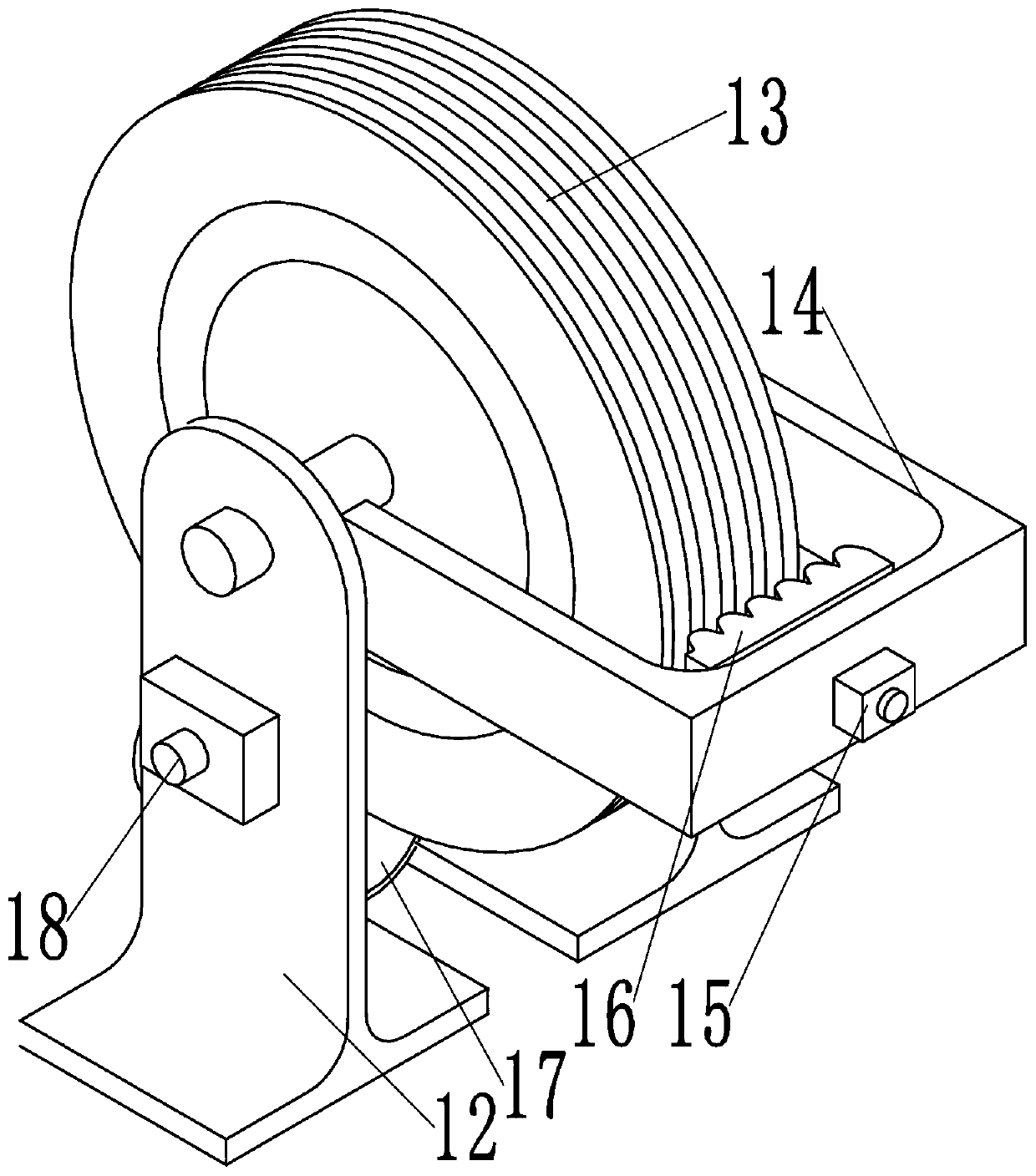

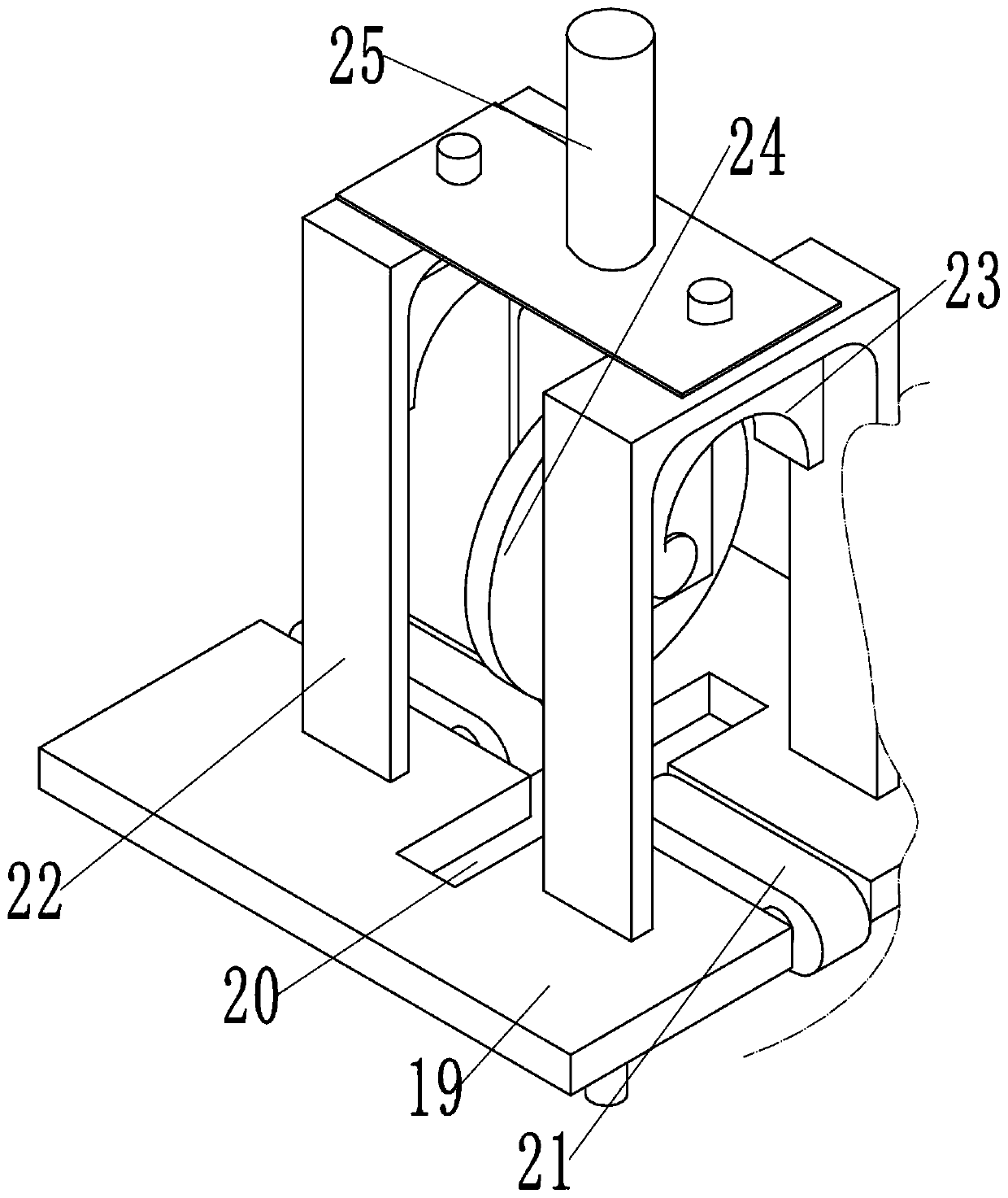

[0038] Such as figure 1As shown, the cable insulation layer sample cutting device of the present embodiment includes a cutting insulation device 11; The cutting insulation machine head 50 center hole on the insulation machine base 49 and the insulation cutting tailstock 54 center holes, the guide rail that is arranged between the insulation cutting machine head 50 and the insulation cutting tailstock 54, moves and is arranged on the guide rail and is connected with the insulation cutting tailstock. The center hole of the seat 54 is coaxial with the insulation-cutting centering frame 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com