Vinylidene fluoride copolymer particles and use thereof

A technology of vinylidene fluoride and copolymer, which is applied in the field of vinylidene fluoride polymer particles and its utilization, can solve the problems of battery characteristics and battery life reduction, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

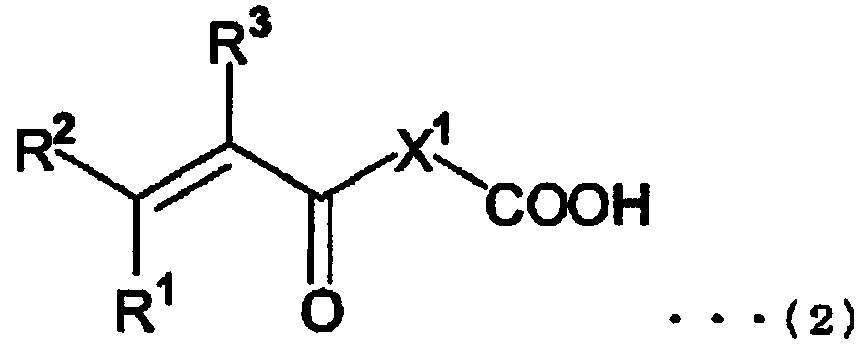

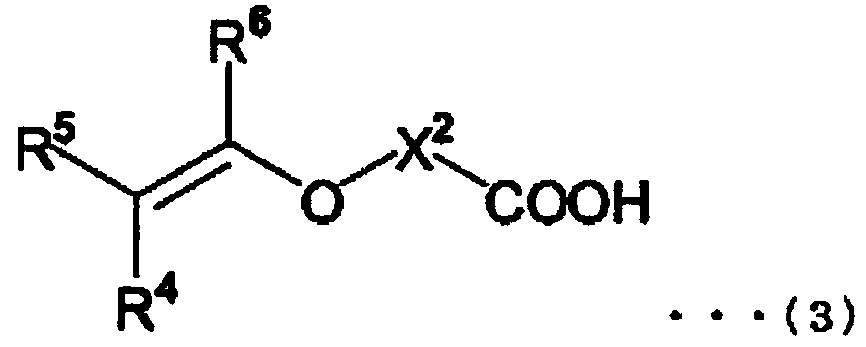

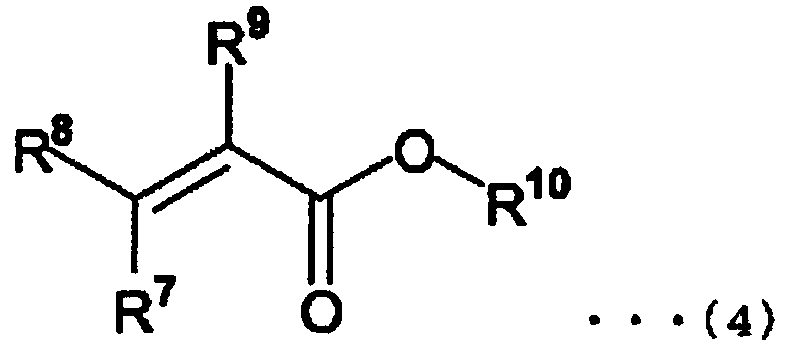

Method used

Image

Examples

Embodiment 1

[0176] 330 parts by mass of ion-exchanged water as a dispersion medium was placed in the autoclave, and degassed by bubbling nitrogen gas for 30 minutes. Next, 1.0 parts by mass of perfluorooctanoic acid ammonium salt (PFOA) was charged as a surfactant, the pressure was increased to 4.5 MPa, and nitrogen replacement was performed three times. Next, 0.05 parts by mass of ethyl acetate as a chain transfer agent, 35 parts by mass of vinylidene fluoride (VDF), and 8.0 parts by mass of hexafluoropropylene (HFP) as another compound were added to the autoclave. Then, after heating up to 80 degreeC with stirring, the 5 wt% ammonium persulfate aqueous solution as a polymerization initiator was put in the amount equivalent to 0.1 mass part in conversion of ammonium persulfate, and superposition|polymerization was started. After the start of the reaction, when the pressure dropped to 2.5 MPa, 56.9 parts by mass of VDF were continuously added so that the pressure in the tank was maintaine...

Embodiment 2

[0178] Except having used monomethyl maleate (MMM) as the compound containing an oxygen atom, polymerization was carried out similarly to Example 1, and the latex containing a particle was obtained. The obtained latex had a solid content concentration of 20.8 wt % and a particle diameter of 150 nm.

Embodiment 3

[0180] Except having used acryloyloxypropyl succinate (APS) as an oxygen atom containing compound, it polymerized similarly to Example 1, and obtained the latex containing a particle. The obtained latex had a solid content concentration of 21.0 wt % and a particle diameter of 150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com