High-precision nail polish color matching instrument adapted to high viscosity

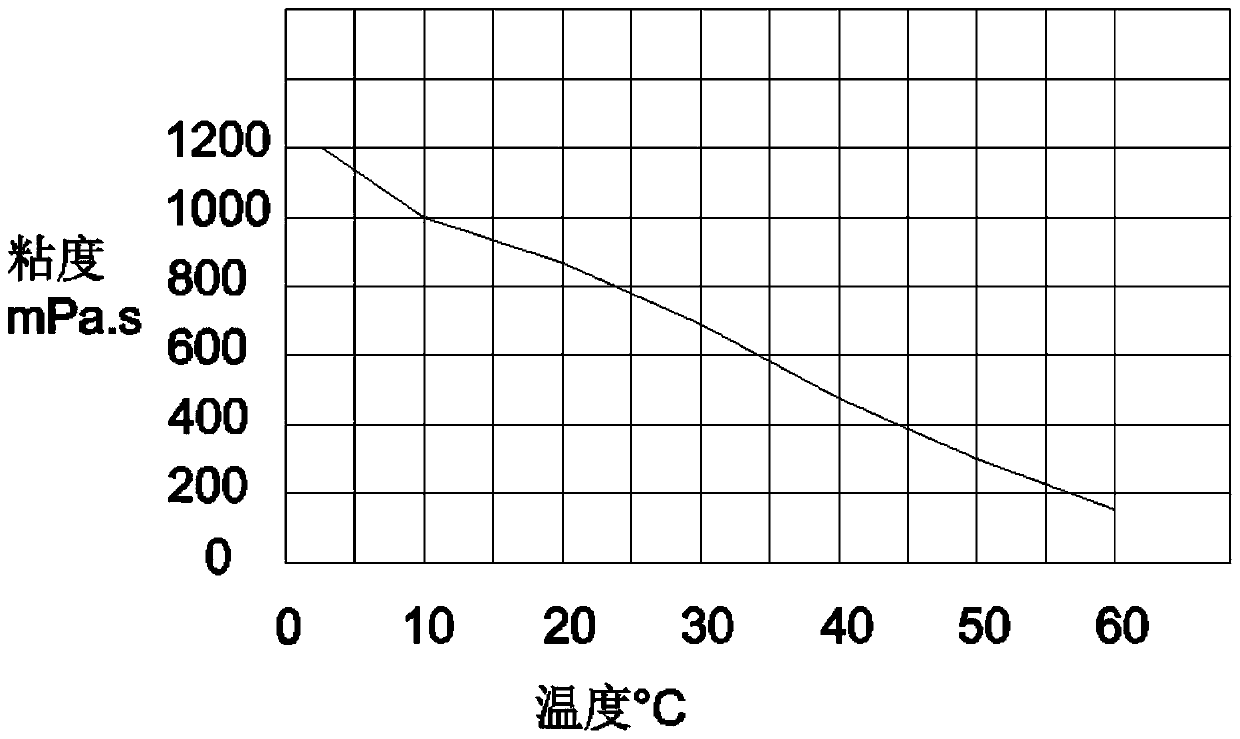

A nail polish, high-precision technology, applied in mixer accessories, chemical instruments and methods, dissolution and other directions, can solve problems such as reducing extrusion speed and accuracy, pipelines are not easy to flow, and cannot reach the collection box, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

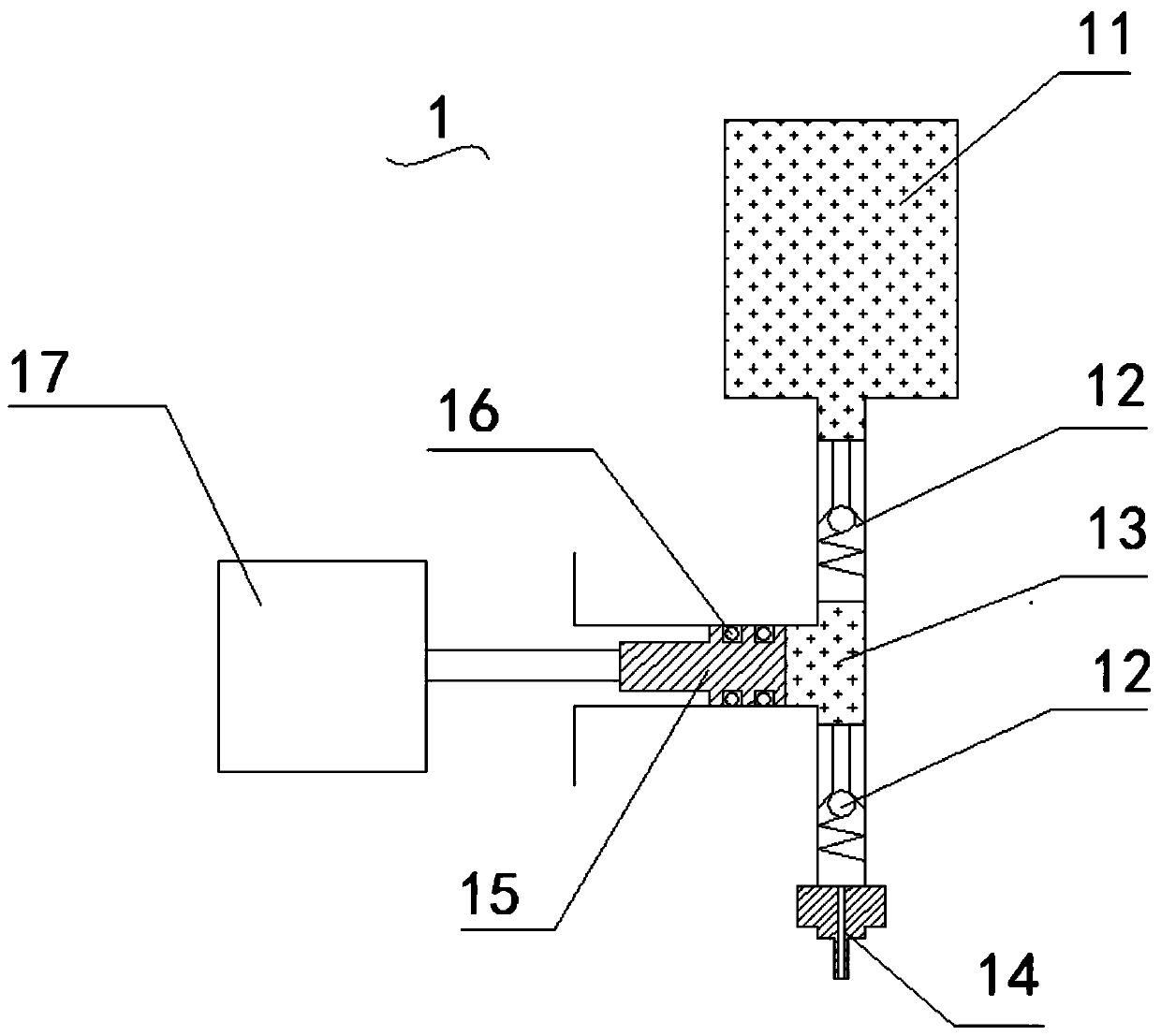

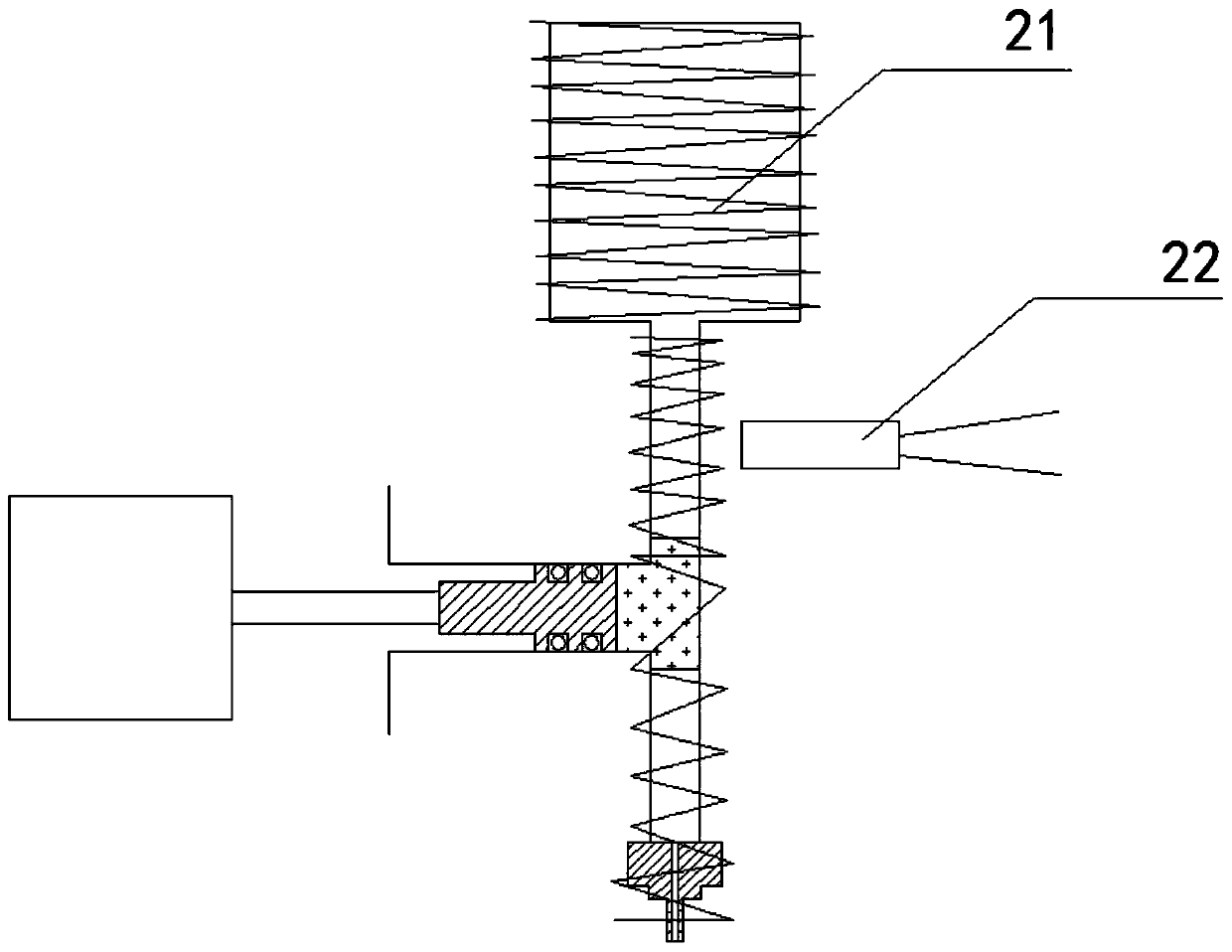

[0019] Such as Figure 1-2 As shown, a high-precision nail polish color matching instrument adapted to high viscosity includes an extruder 1 and an extruder heating device 2 positioned on the side of the extruder 1, wherein the extruder 1 includes a storage tank located above The liquid chamber 11, the high-pressure injection chamber 13 below the liquid storage chamber 11 is composed of a feed check valve 12 at the feed place, a high-pressure piston 15 and a check valve 12 at the discharge place. When the high-pressure piston 15 is pulled, the liquid storage The one-way valve 12 at the cavity 11 is opened, and the liquid in the liquid storage cavity 11 is sucked to the high-pressure injection cavity 13; when the hig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap