3D pottery clay printing robot and printing method thereof

A robot and ceramic clay technology, which is applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of limited printing range of clay printing robots, achieve flexible sliding, facilitate free movement, and reduce the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

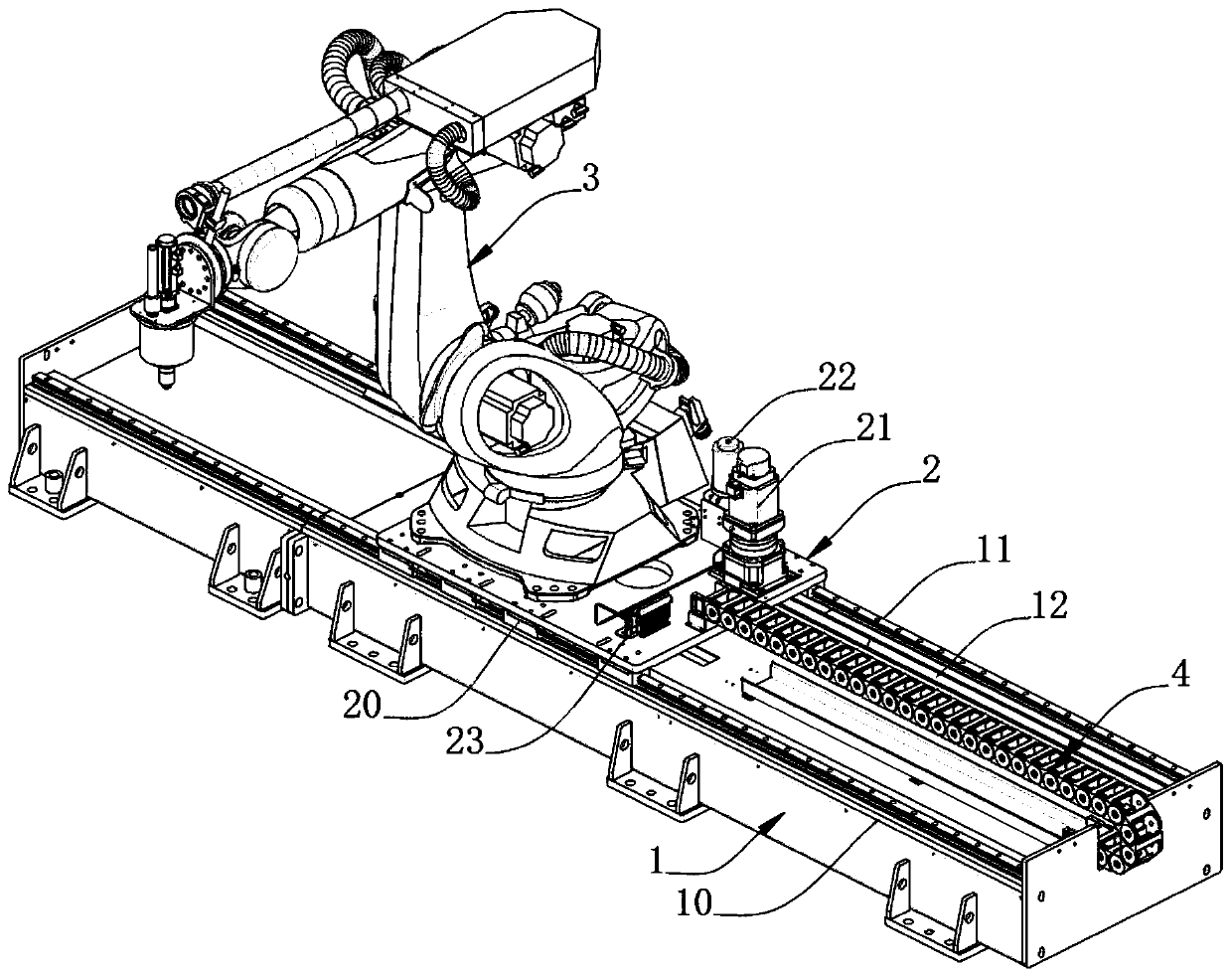

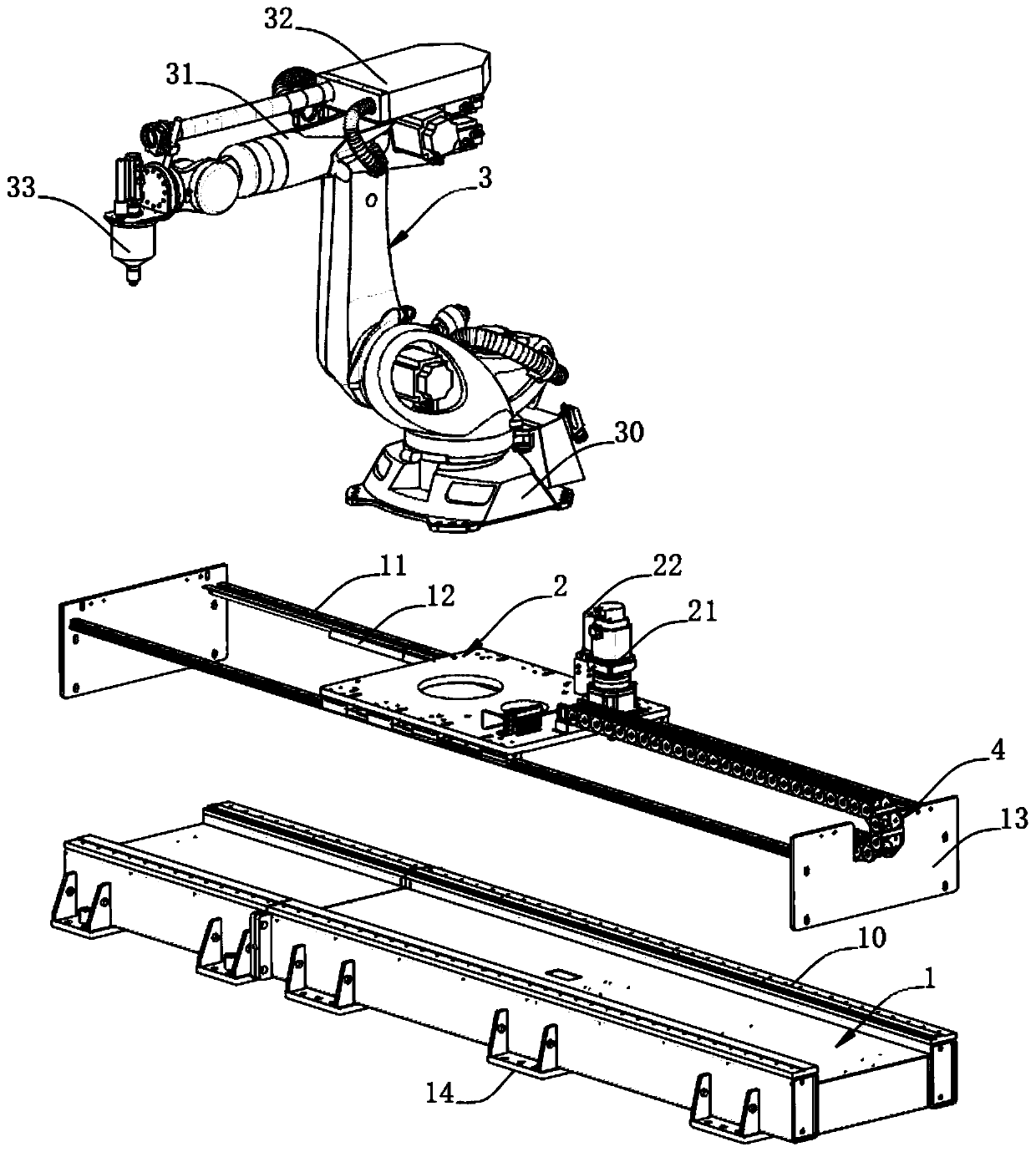

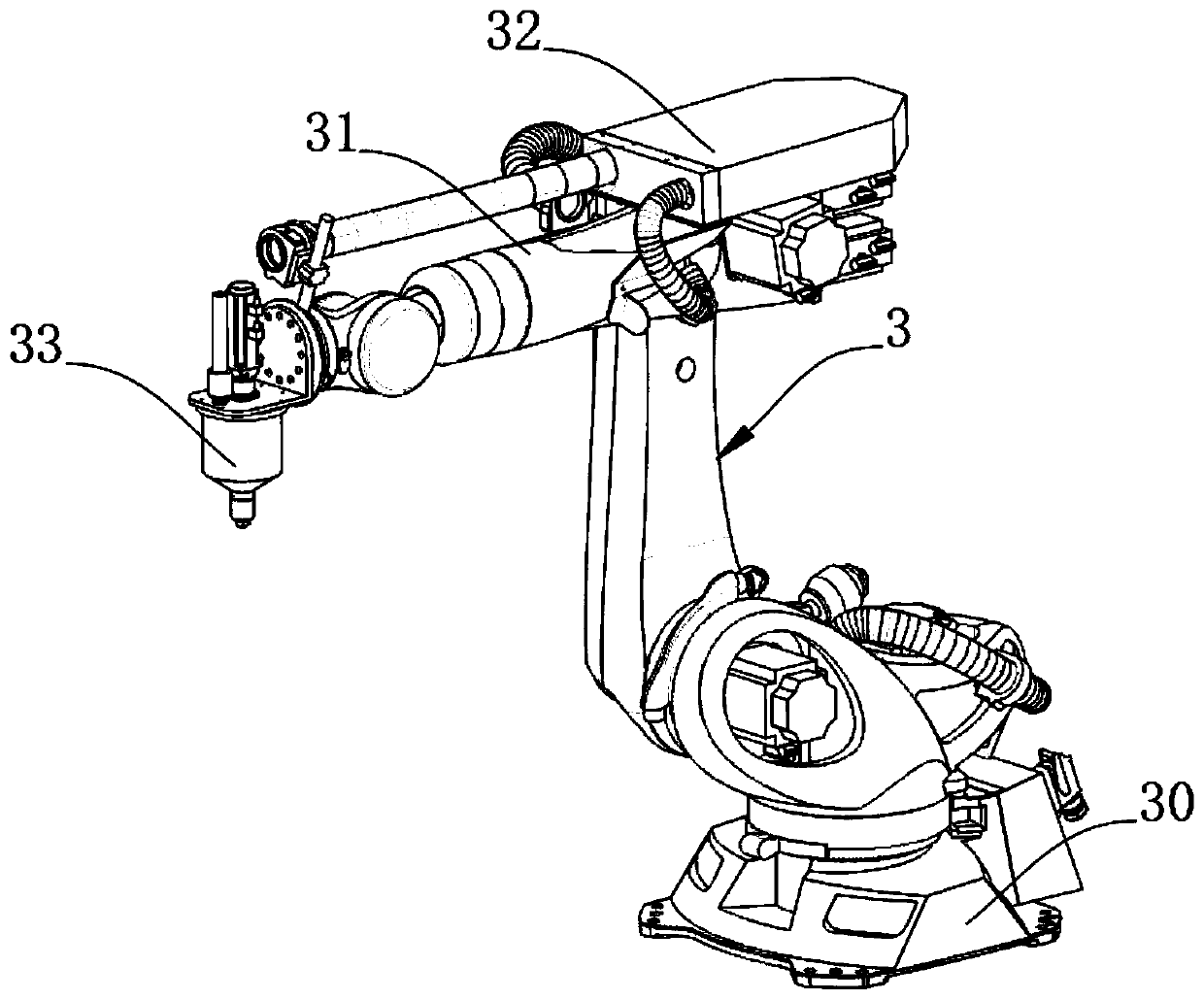

[0032] A kind of 3D ceramic clay printing robot, in order to make the whole robot arm move freely further, the inventor has improved fixed frame 1 and set movable platform 2, as a preferred embodiment, as figure 1 , figure 2 and image 3 As shown, it includes the fixed frame 1 and the machine arm 3 arranged above it. The top of the fixed frame 1 is successively provided with a movable table 2 and a drag chain 4. The top sides of the fixed frame 1 are fixed with a fixed plate 10 by bolts. The fixed plate 10 The top surface of the movable platform 2 is fixed with a slide rail 11 by bolts, and the top surface of one of the fixed plates 10 is also fixed with a rack 12 by bolts. The two sides of the bottom of the movable table 2 are fixed with a number of sliders 20 by bolts. One end of the slider 20 is provided with a The chute 200 is slidably connected with the slide rail 11. A motor 21 is fixed by a bolt at a corner of the top surface of the movable table 2. The output shaft o...

Embodiment 2

[0040] As the second embodiment of the present invention, in order to make the movable table 2 slide noiselessly and flexibly, the inventor improved the slider 20 and provided a lubricating pump 22, as a preferred embodiment, as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, one side of the motor 21 is fixed with a lubricating pump 22 by bolts, the oil outlet of the lubricating pump 22 is plugged with an oil pipe 220, one end of the oil pipe 220 is plugged with an oil separator 23, and the bottom of the oil separator 23 is plugged with a Several delivery pipes 230 .

[0041] In this embodiment, the movable table 2 is made of steel plate, so that it has a strong bearing capacity and is thus durable.

[0042] Further, one end of the slider 20 is provided with an oil inlet hole 201 , and the oil inlet hole 201 does not penetrate through the slider 20 , so as to prevent the oil entering the oil inlet hole 201 from leaking out.

[0043] Specifically, the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com