Electric surfboard and manufacturing process of electric surfboard

A manufacturing process and surfboard technology, applied in the field of water equipment, can solve the problems of broken electric surfboards, insufficient strength, waste of front-end costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

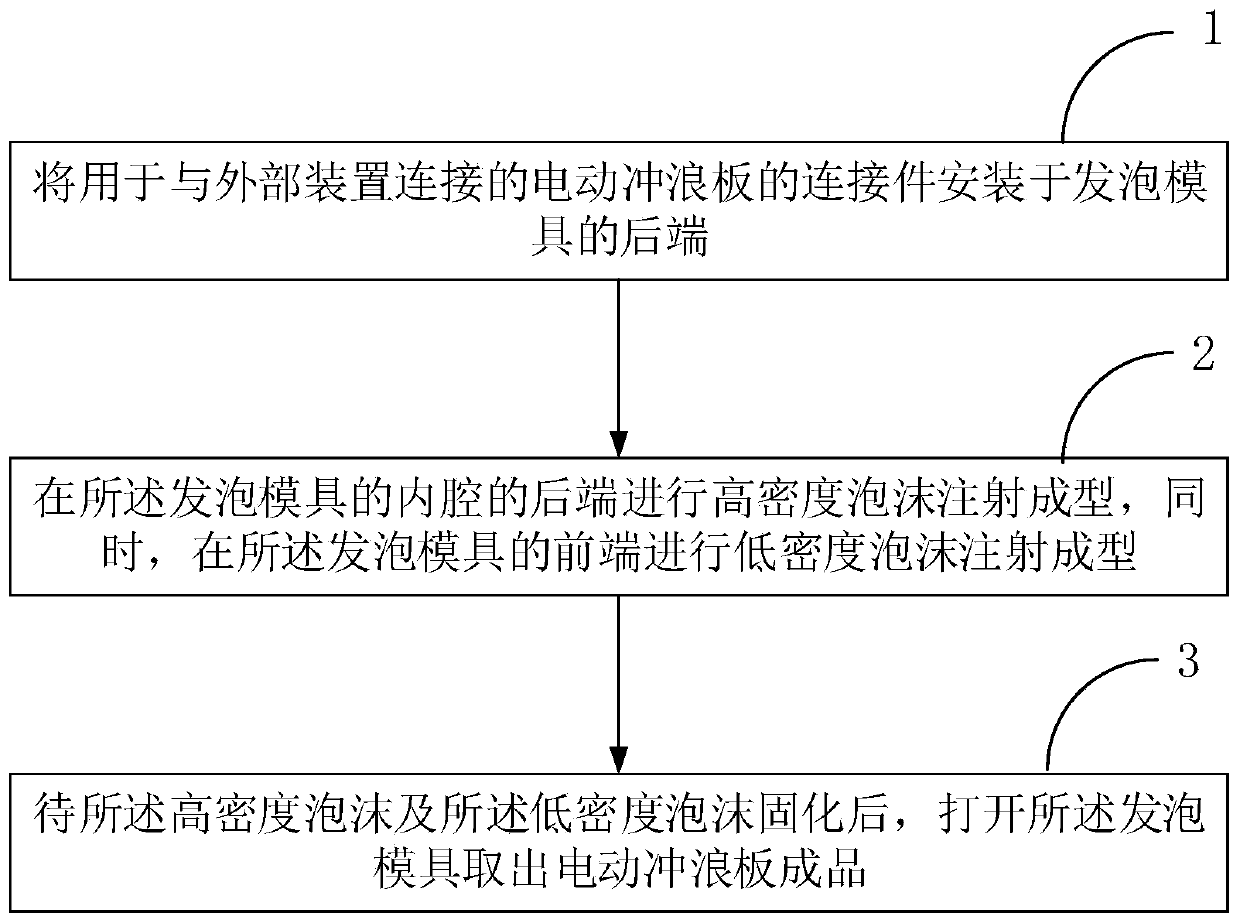

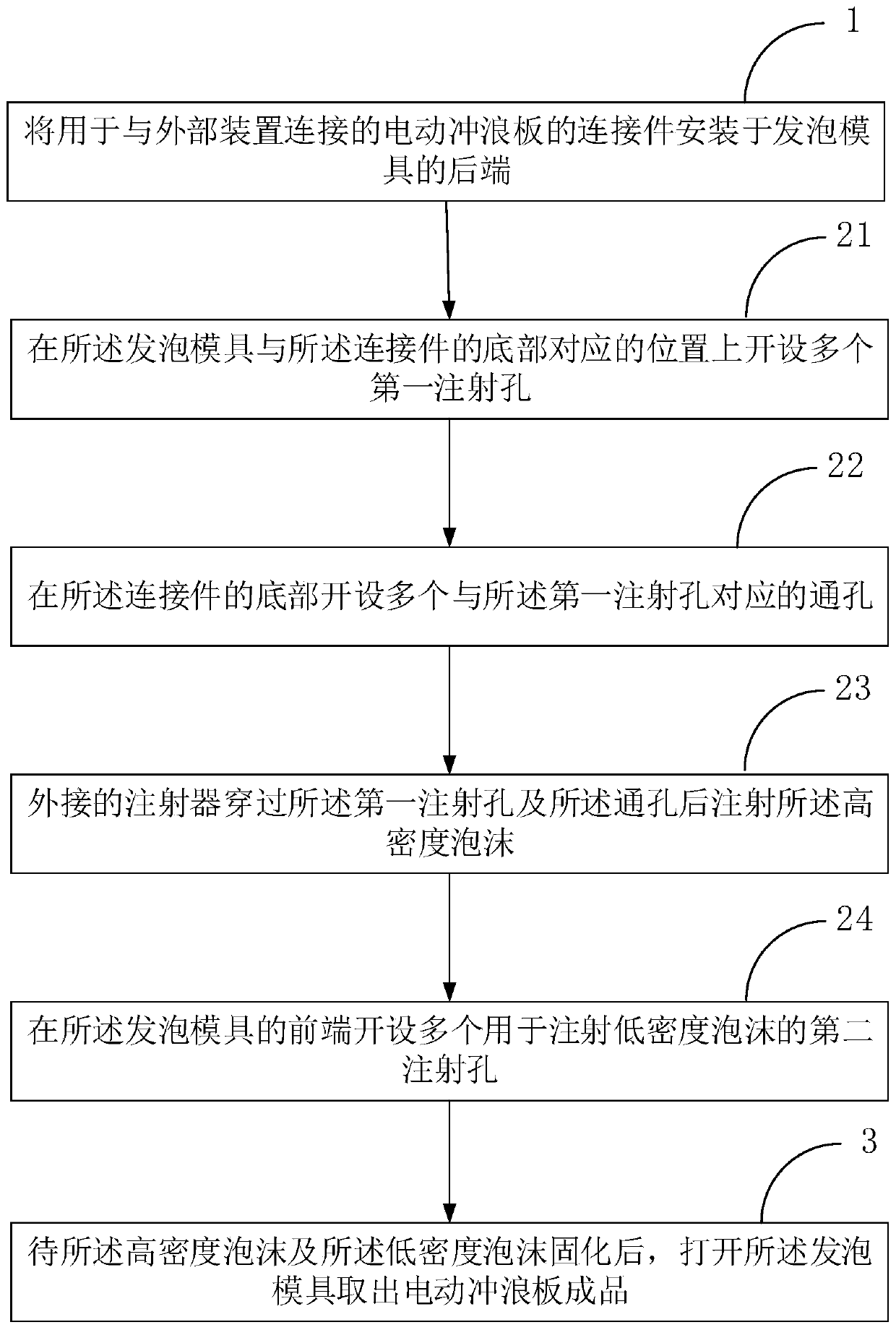

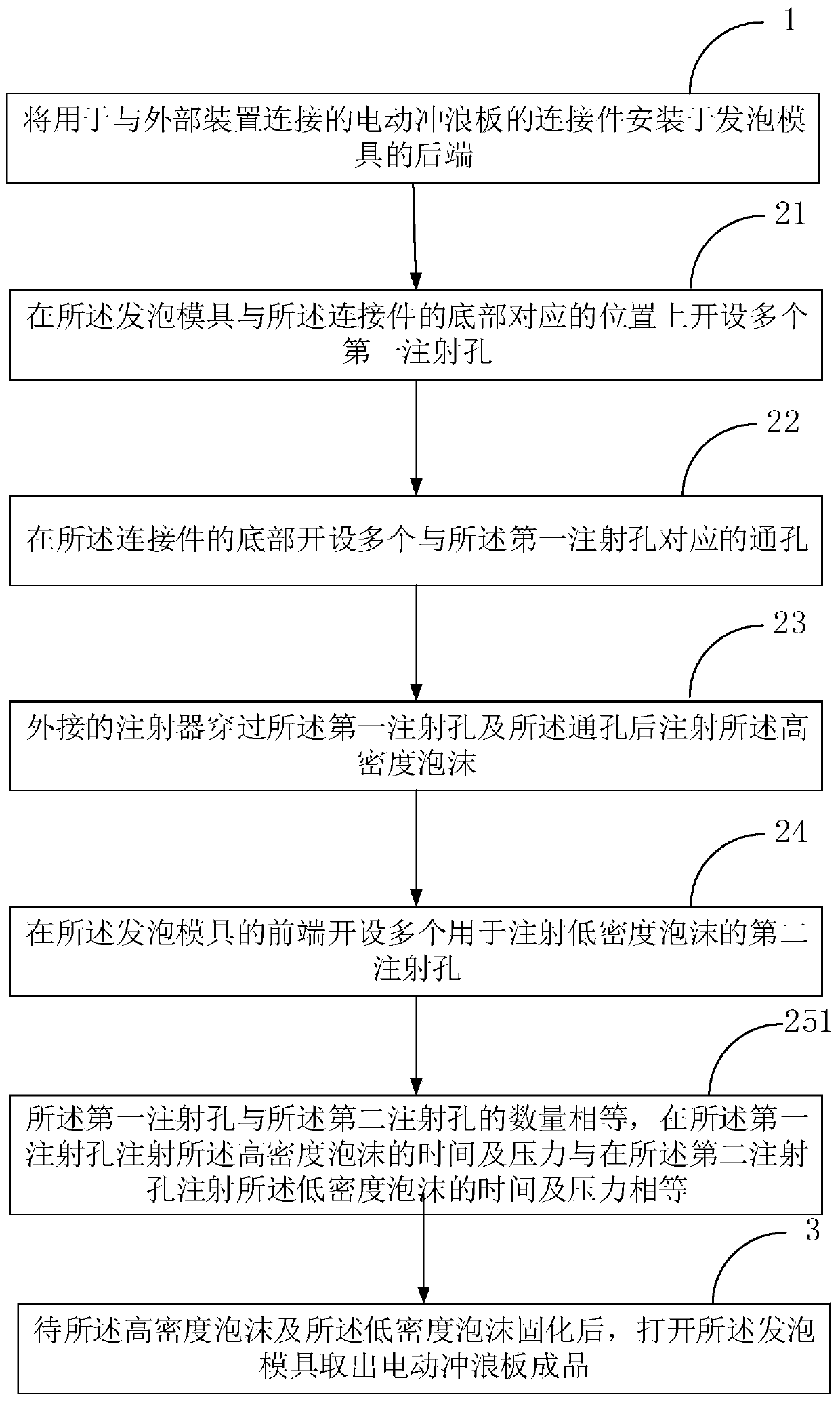

[0050] Present embodiment proposes a kind of electric surfboard manufacturing process, as figure 1 , 8 , which includes the following steps:

[0051] Step 1. Install the connector 10 of the electric surfboard used for connecting with the external device on the rear end of the foaming mold;

[0052]As mentioned above, it is worth further explaining that the connecting piece 10 is used to connect with external devices, for example, it can be used for externally connecting tail fins, or can be used for externally connecting hydrofoils, masts, etc., so as to provide power for electric surfboards through external devices. A power supply component, a control component and the like may be arranged inside the connector 10 . The connector 10 may be in the shape of a box with a cavity inside. In this embodiment, the internal structure of the connector 10 is installed in advance. Specifically, the connecting piece 10 is pre-installed at the rear end of the inner cavity of the foaming...

Embodiment 2

[0086] A kind of electric surfboard 100, see Figure 8 , which is made by the electric surfboard manufacturing process of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com