Locking mechanism, crane boom and autocrane

A technology of locking mechanism and boom, which is applied in the direction of cranes, etc., can solve the problems of the big boom, the extension, the damage of the pulley at the tip of the boom, etc., and achieve the effect of wide industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

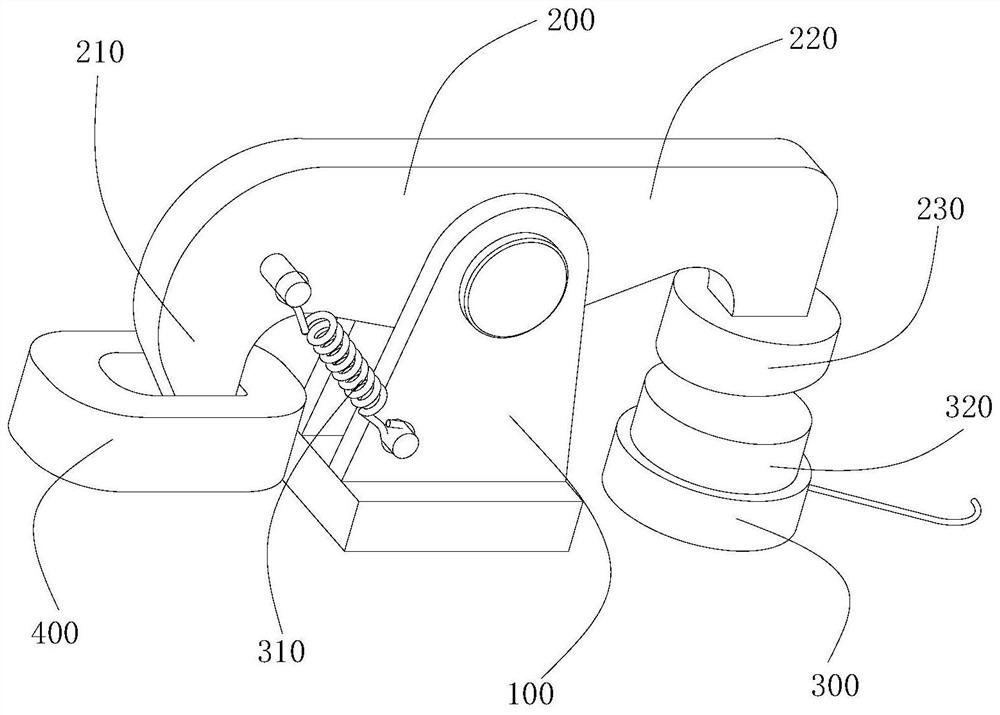

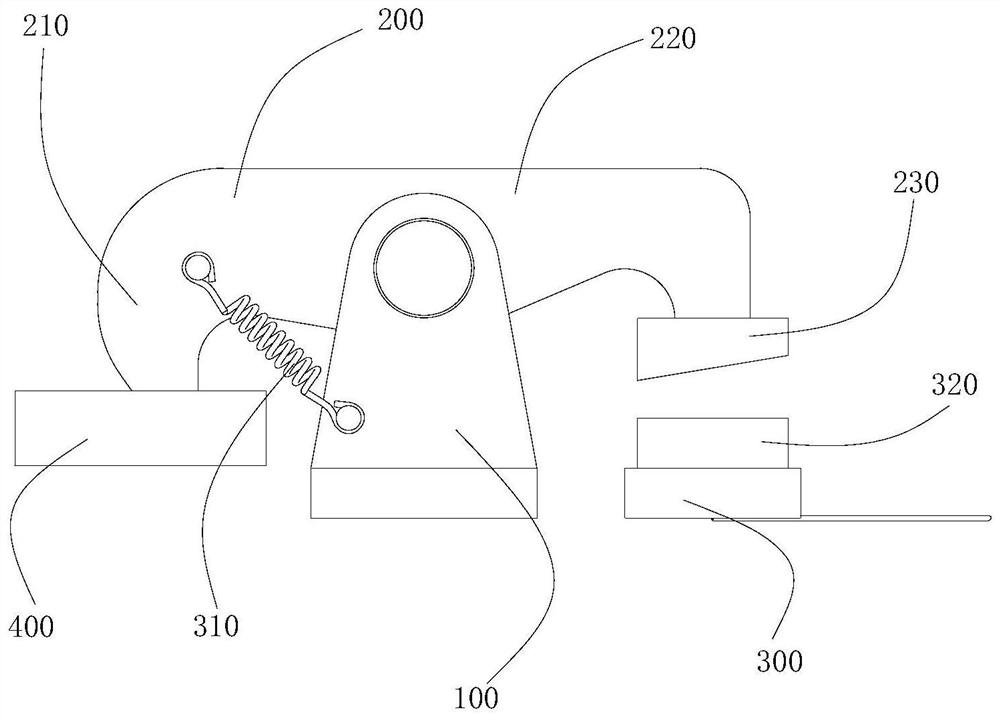

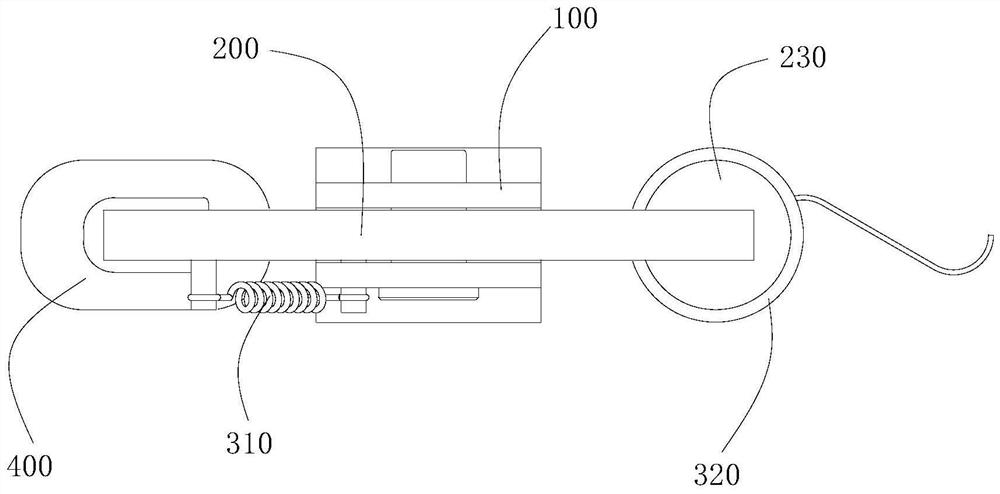

[0046] see figure 1 , the locking mechanism of this embodiment is applied to the boom of a truck crane, and includes a mounting base 100 , a connection assembly 200 and an electromagnetic drive assembly 300 .

[0047] The mounting base 100 is welded on the basic arm of the boom; the connecting assembly 200 is rotatably connected with the mounting base 100 through a pin shaft, and the electromagnetic drive assembly 300 drives the connecting assembly 200 to rotate relative to the mounting base 100 through electromagnetic, so as to be connected with the lifting arm The joint arm is connected or disconnected.

[0048] When the jib is in the horizontal position and the truck crane needs to fix the joint arm relative to the basic arm during the travel, the electromagnetic drive assembly 300 drives the connection assembly 200 to rotate to connect with the joint arm, so that the connection assembly 200 is connected The joint arm is fixed relative to the basic arm, and the joint arm i...

Embodiment 2

[0058] This embodiment provides a lifting arm, including the locking mechanism provided in the first embodiment, a basic arm and a plurality of joint arms, and the locking mechanism provided in the first embodiment is installed on the basic arm. The mounting base 100 is welded on the basic arm of the boom; the connecting assembly 200 is rotatably connected with the mounting base 100 through a pin shaft, and the electromagnet 320 is installed on the basic arm of the lifting arm, and the electromagnetic connection base of the connecting assembly 200 is connected through the electromagnetic 230, the stopper 400 is installed on the jib of the boom, and the stopper 400 is connected to or disengaged from the locking part 210 of the connection assembly 200.

[0059] It works as follows:

[0060] When the truck crane is not needed for lifting operations, the hydraulic system of the truck crane is controlled so that the whole boom is in a retracted state and extends along the horizonta...

Embodiment 3

[0063] This embodiment provides a truck crane, including a car body and the jib provided in the second embodiment, and the jib provided in the second embodiment is installed on the car body. The electromagnetic drive assembly 300 is connected with the power supply device of the truck crane.

[0064] During the traveling process of the truck crane, the joint arm is locked to prevent the joint arm from leaping up to ensure the safety of the truck crane; when the boom is working, the joint arm can be unlocked for easy use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com