Curvature regulating member and power supply device

A technology of bending control and components, which is applied in the field of power supply devices and bending control components, and can solve problems such as damage to connecting hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

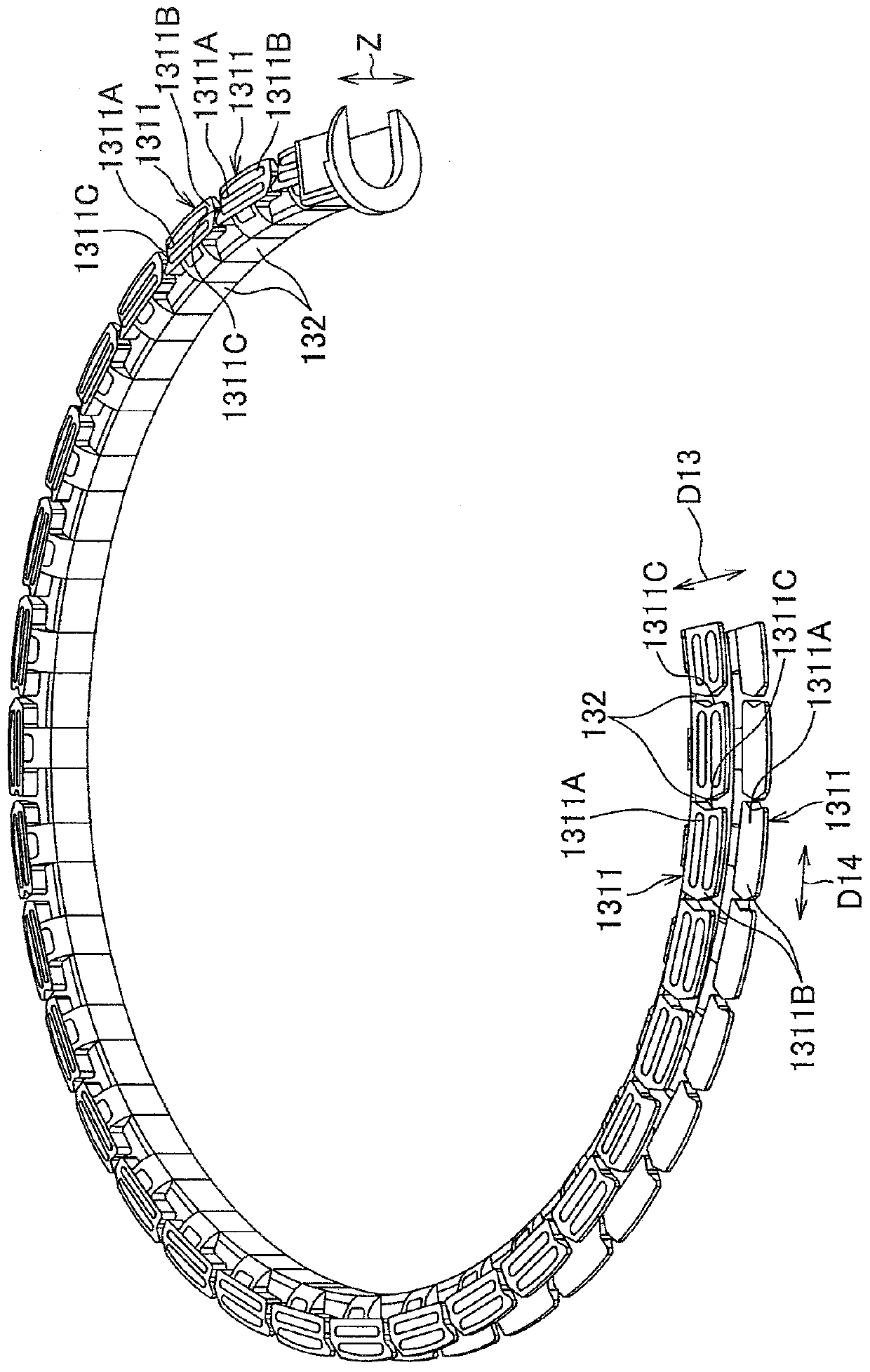

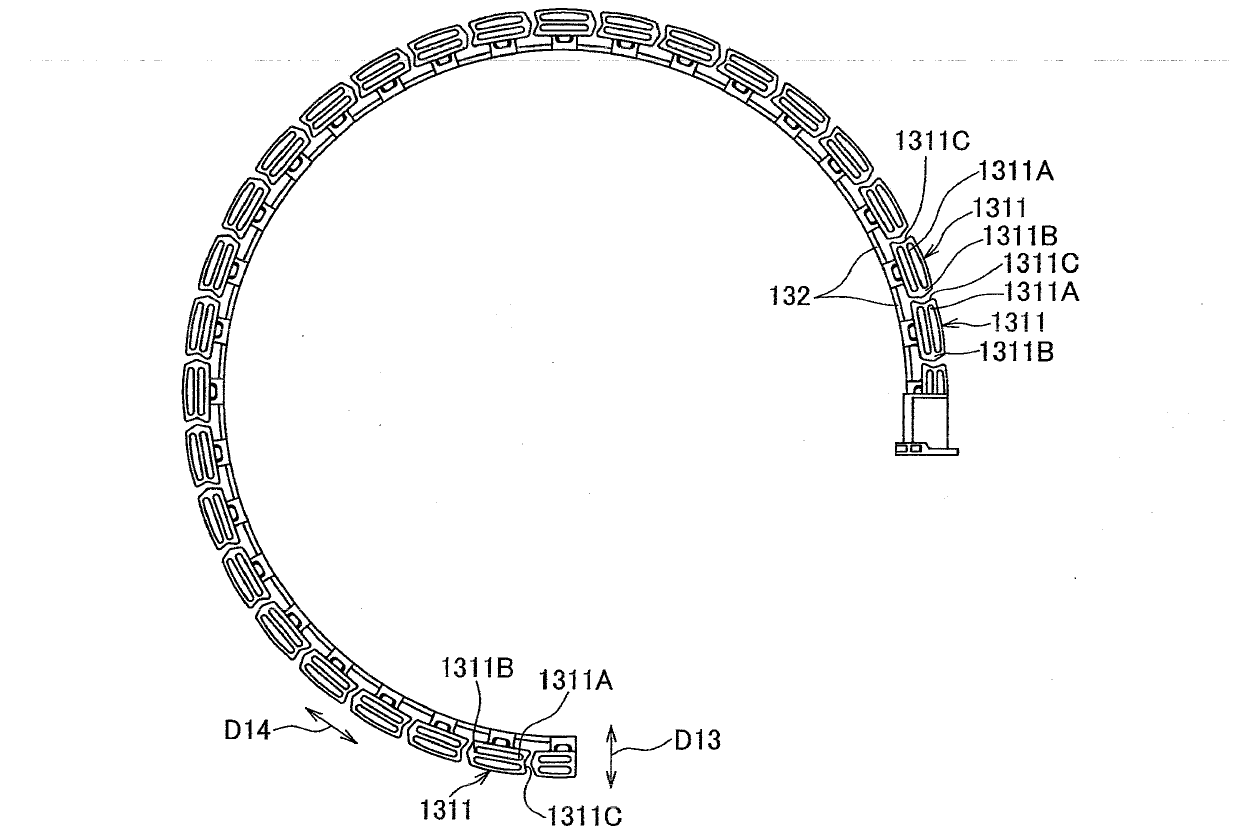

[0035] Hereinafter, a bending control member and a power supply device according to an embodiment of the present invention will be described with reference to the accompanying drawings.

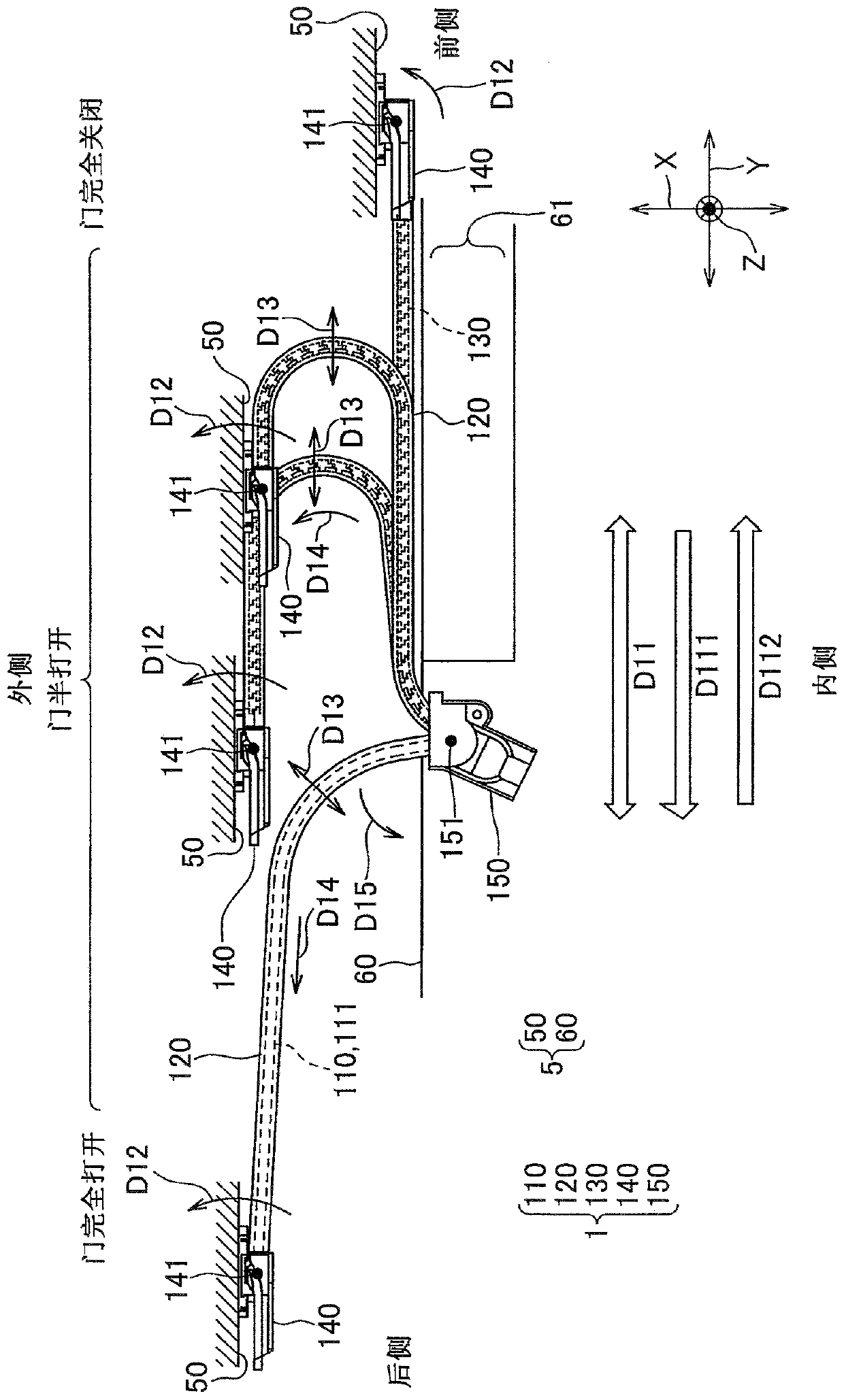

[0036] figure 1 is a view showing a power supply device to which a bending control member according to an embodiment of the present invention is applied. The power supply device 1 of the present embodiment is configured to be mounted to a vehicle 5 . The power supply device 1 is configured to supply electric power from a power source (not shown) arranged on the vehicle body 60 side to an electronic device (not shown) arranged on the sliding door 50 (sliding member) via a wire harness 110 . exist figure 1 Among them, the right side corresponds to the front side of the vehicle 5 , the left side corresponds to the rear side of the vehicle 5 , the upper side corresponds to the outer side of the vehicle 5 , and the lower side corresponds to the inner side of the vehicle 5 . That is, in the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com