A multi-channel atomizer and gasification reaction operation method

A technology of gasification reaction and operation method, which is applied in gasification process, gasification device feeding tool, granular/powder fuel gasification, etc. It can solve the problems of conventional mixing hazards, achieve simple and reliable connection, and prevent overheating. , the effect of reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

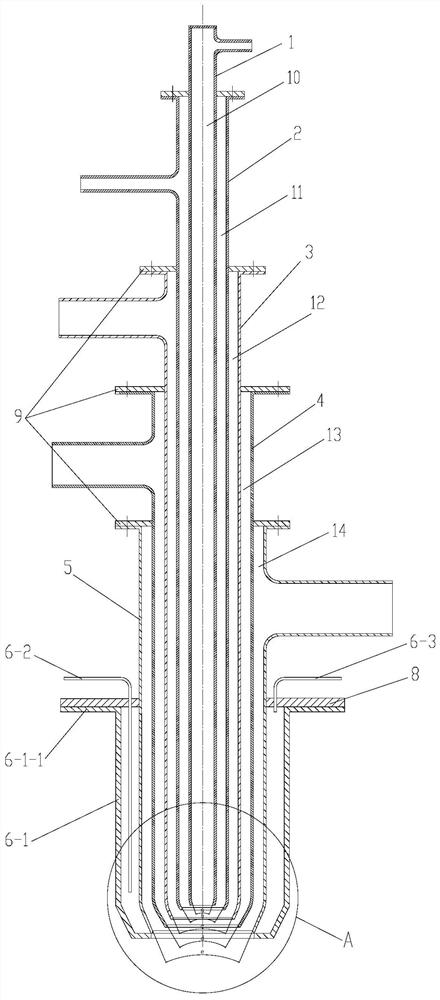

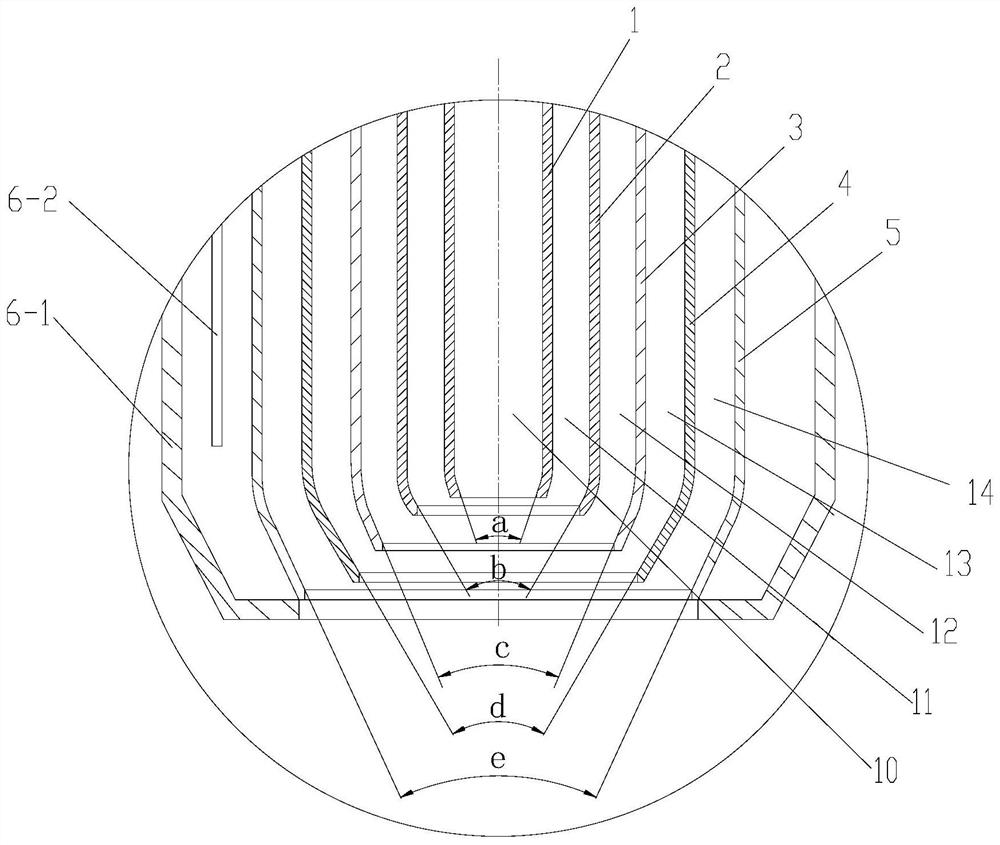

[0043] In this example, if figure 1 and figure 2As shown, the multi-channel atomizer is a five-channel atomizer, and the five-channel atomizer includes a five-channel atomization structure and a cooling protection structure arranged outside the five-channel atomization structure, so The five-channel atomization structure includes 5 casings with different inner diameters and coaxially stacked from inside to outside in the order of inner diameters from small to large, and the 5 casings are coaxially stacked from inside to outside The first sleeve 1, the second sleeve 2, the third sleeve 3, the fourth sleeve 4 and the fifth sleeve 5, the side wall of the first sleeve 1, the side wall of the second sleeve 2 , the side wall of the third sleeve 3, the side wall of the fourth sleeve 4 and the side wall of the fifth sleeve 5 are all provided with inlet ports, and the 5 sleeves have 3 gas flow channels and 2 liquid The three gas flow channels include the first gas flow channel 10 fo...

Embodiment 2

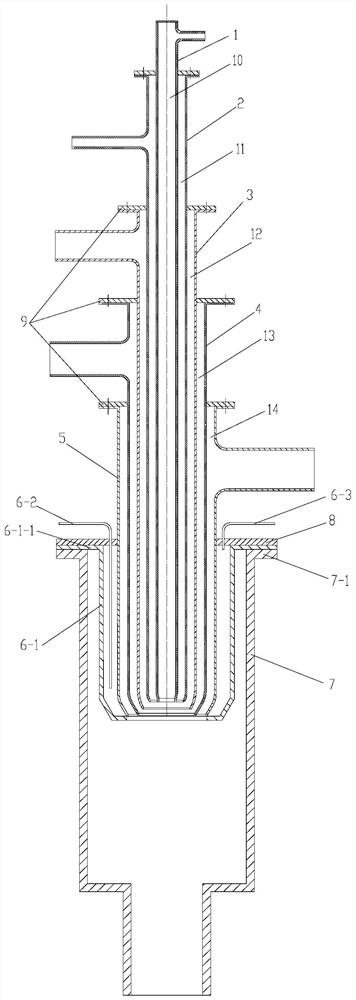

[0055] In this example, if Figure 4 and 5 As shown, the multi-channel atomizer is a seven-channel atomizer, and the seven-channel atomizer includes a seven-channel liquid slurry atomization structure and is arranged outside the seven-channel liquid slurry atomization structure The cooling protection structure of the seven-channel liquid slurry atomization structure includes 7 sleeves with different inner diameters and coaxially stacked from the inside to the outside in the order of inner diameters from small to large, and the 7 sleeves are respectively It is the first casing 1, the second casing 2, the third casing 3, the fourth casing 4, the fifth casing 5, the sixth casing 15 and the seventh casing which are coaxially stacked sequentially from the inside to the outside. 16, the side wall of the first casing 1, the side wall of the second casing 2, the side wall of the third casing 3, the side wall of the fourth casing 4, the side wall of the fifth casing 5, the side wall o...

Embodiment 3

[0064]The difference between this embodiment and Embodiment 2 is that the angle a at the outlet of the first gas flow channel 10 is 45°, the angle b at the outlet of the first liquid flow channel 11 is 60°, and the flow path of the second gas flow channel 12 is Outlet included angle c=75°, second liquid channel 13 outlet included angle d=90°, third gas channel 14 outlet included angle e=115°, third liquid channel 17 outlet included angle f =130°, the included angle g at the outlet of the fourth gas channel 18=145°.

[0065] In this embodiment, the height difference between the bottom end surface of the first sleeve 1 and the bottom end surface of the second sleeve 2 is 25 mm; The height difference between the bottom end surface of the third casing 3 and the bottom end surface of the fourth casing 4 is 20mm; the bottom end surface of the fourth casing 4 and the bottom end surface of the fifth casing 5 The height difference between the bottom end surface of the fifth casing 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com