Construction method for mid-span closure section of prestressed concrete continuous beam bridge and continuous rigid framework

A construction method and a technology for closing sections, which are applied in bridges, bridge materials, bridge construction, etc., can solve the problems of insufficient construction space for hanging baskets, insufficient compressive stress reserves, and small segment lengths, etc., to improve mid-span deflection and even cracking , easy to operate, and full conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

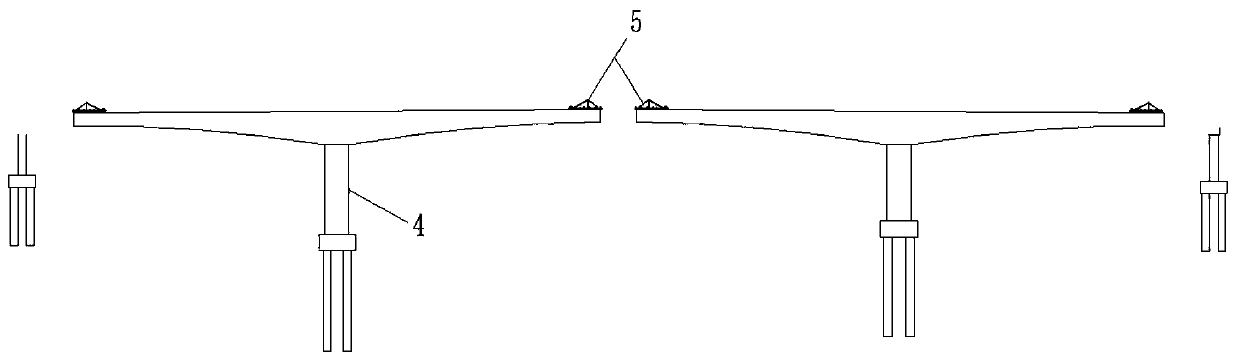

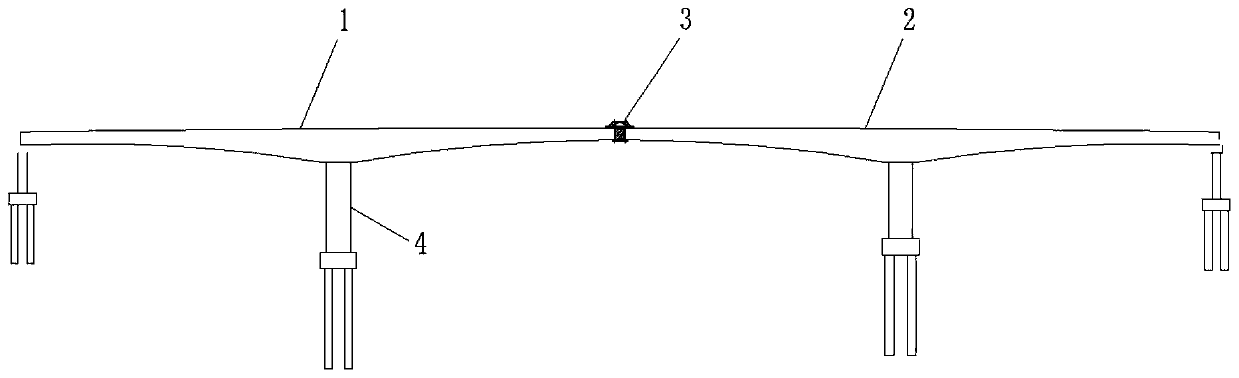

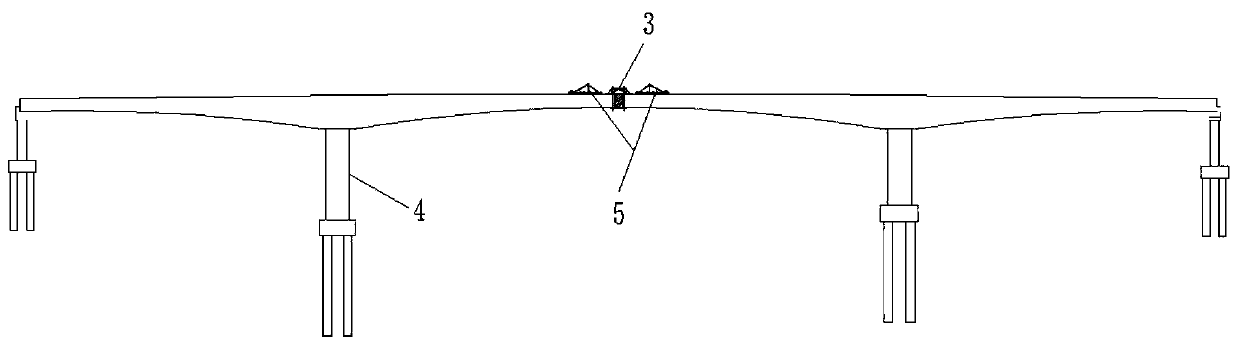

[0023] figure 1 Schematic diagram of the construction structure of the hanging basket; figure 2 It is a structural schematic diagram of the existing construction method of the closing section; image 3 It is a structural schematic diagram of the construction method of the present invention for closing up the section; Figure 4 It is the flow chart of the existing construction method of the closing section; Figure 5 It is a flow chart of the construction method of the present invention in the closing section;

[0024] to combine figure 2 and Figure 4 As shown, the construction steps of the existing prestressed concrete continuous girder bridge and the mid-span closing section of the continuous rigid frame are S1: hanging baskets between adjacent girders to the mid-span closing section; S2: removing the hanging Basket, install the hanger and stiffener of the closing section; S3: Bind the steel bars and pour the concrete of the closing section to complete the closing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com