An energy-saving automatic impurity removal device for farmland canals

An automatic technology for farmland canals, applied in the field of farmland canals, can solve problems such as accumulation of debris blocking the canal, untimely treatment and interception of debris accumulated in the canal, and attachment to both sides of the canal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

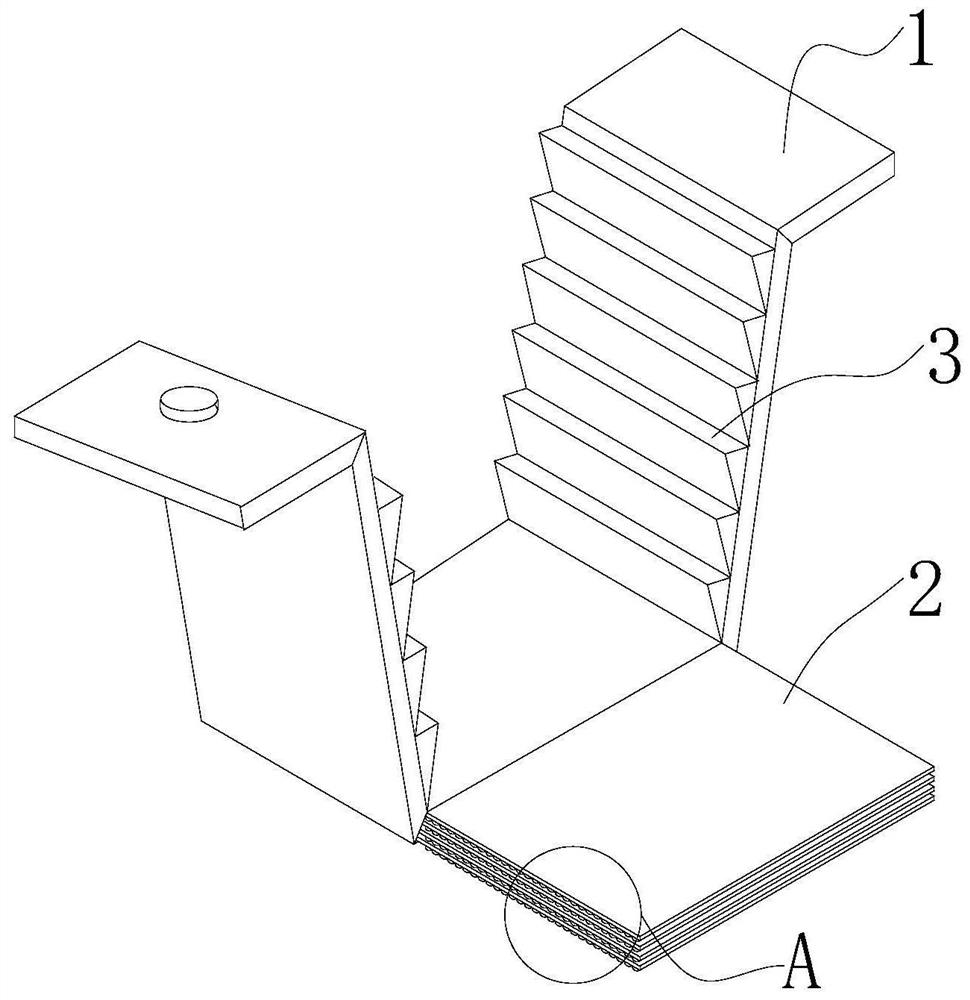

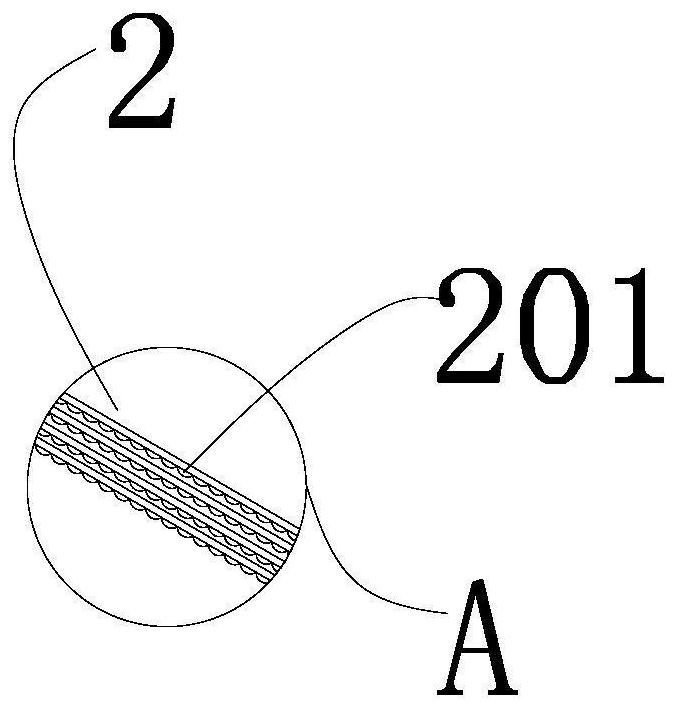

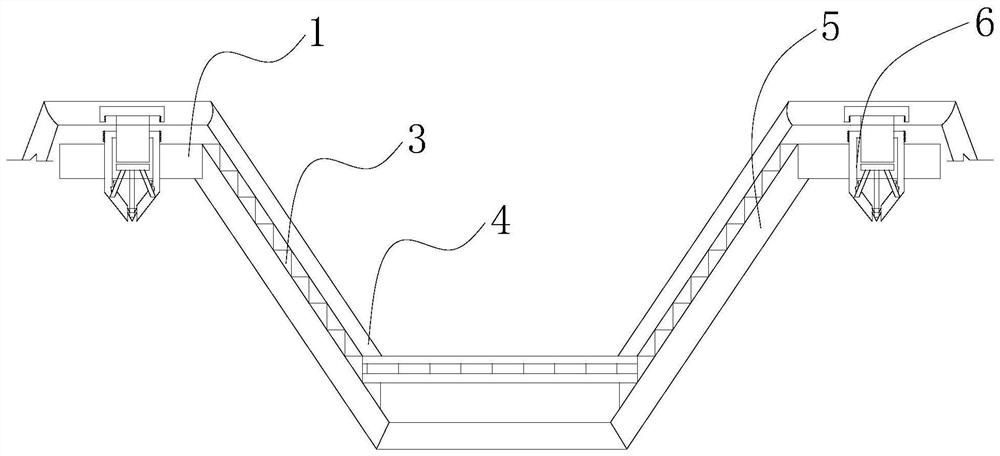

[0036] see Figures 1 to 8 , is a disassembled structural schematic diagram and a three-dimensional structural schematic diagram of an energy-saving automatic impurity removal device for farmland canals in an embodiment of the present invention.

[0037] The invention provides an energy-saving automatic impurity removal device for farmland canals, which includes a drainage mechanism, a splicing mechanism, a dirt-blocking mechanism and a fixing mechanism. The mechanism is fixedly connected to both sides of the drainage mechanism,

[0038] The drainage mechanism includes a water channel fixing plate 1, a limiting plate 3 and an inclined support plate 5, the water channel fixing plate 1 is fixedly connected to the side of the inclined supporting plate 5, and the limiting plate 3 is fixedly installed on the slope of the inclined supporting plate 5 ;

[0039] The splicing mechanism includes a water channel splicing plate 2 and a sliding limit block 201, and the sliding limit bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com