Machine room maintenance overhauling device and method of multifunctional mobile working platform

A technology of working platform and maintenance device, which is applied in the field of electric power, can solve the problems of complex machine room environment and low maintenance efficiency of maintenance equipment, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

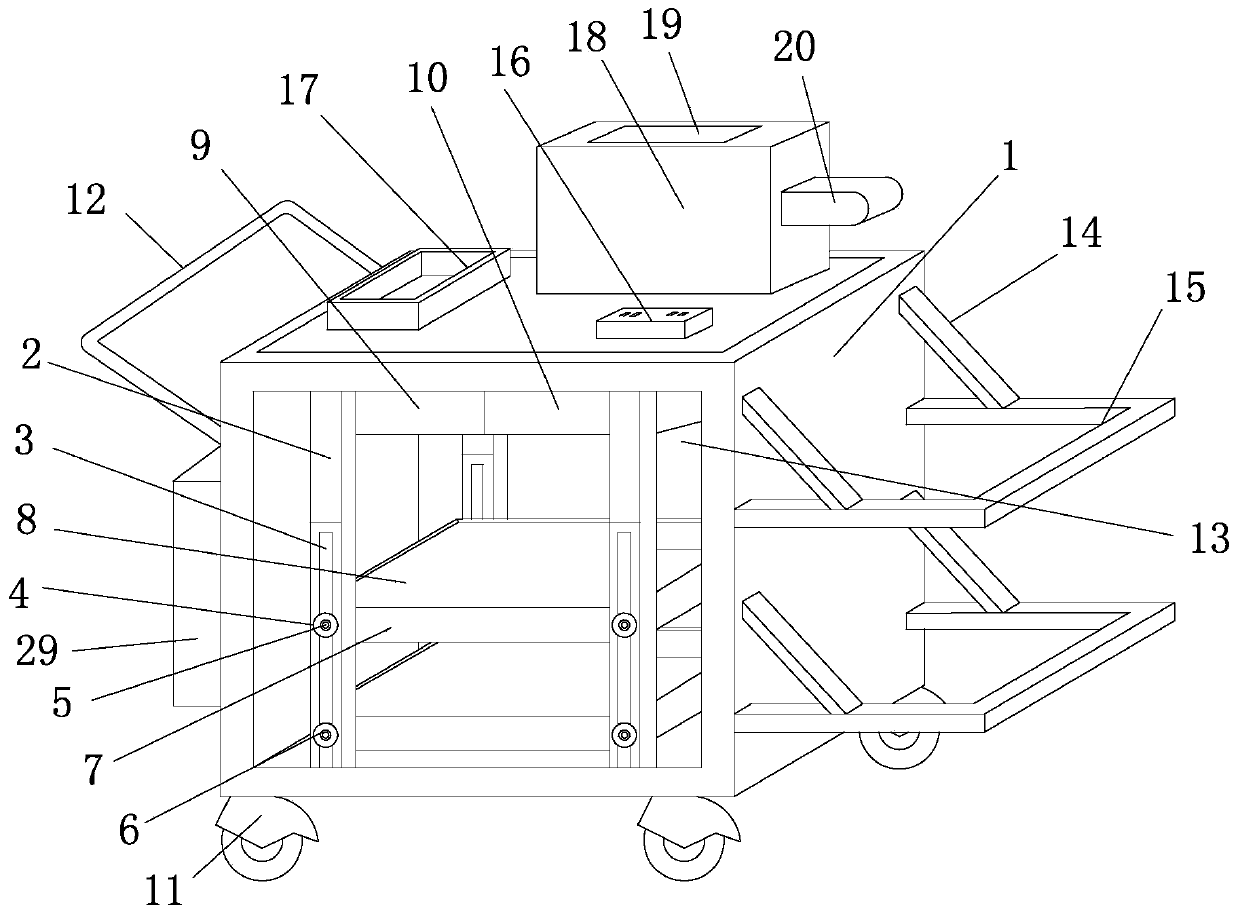

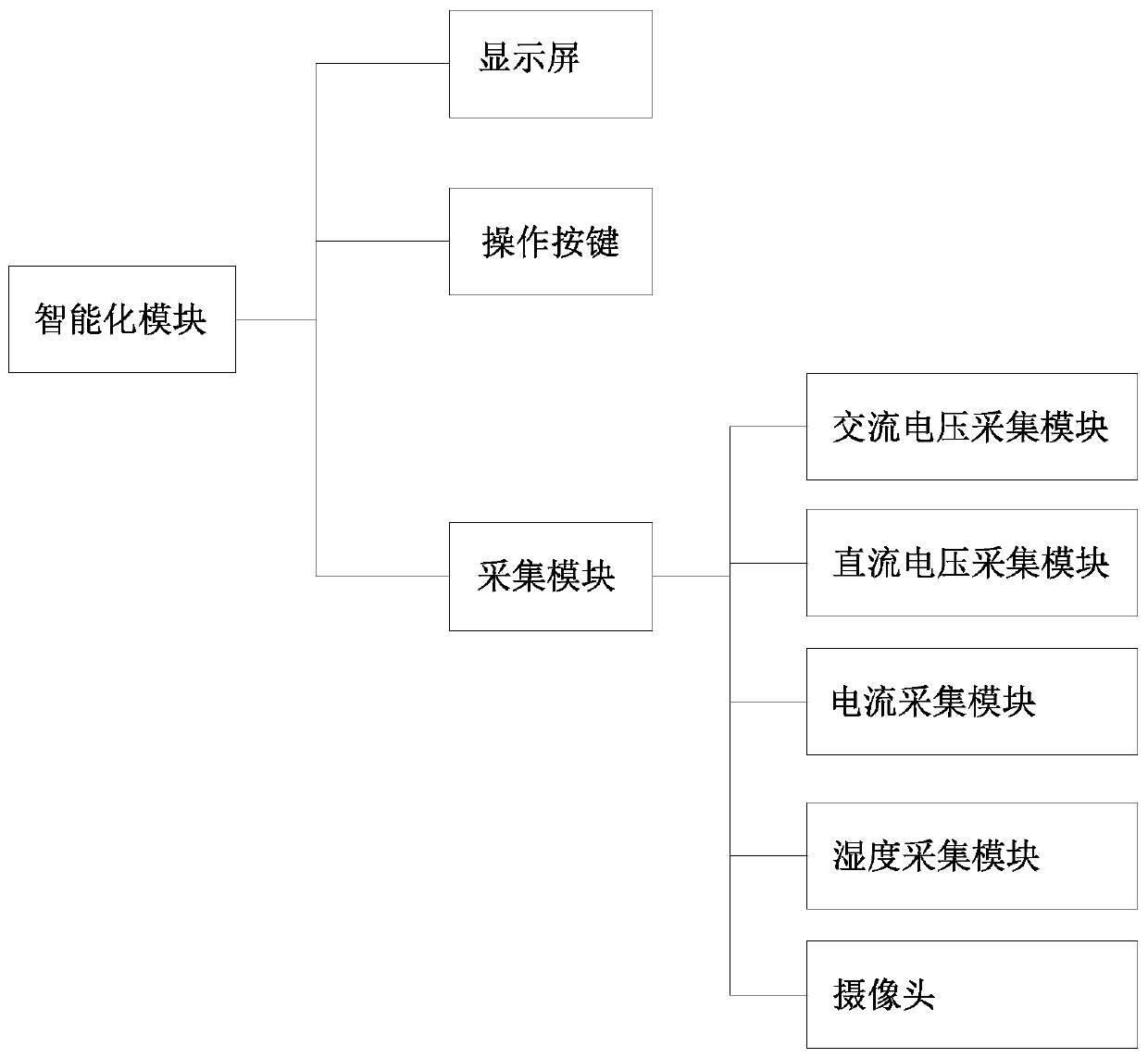

[0027] Such as figure 1 and figure 2 As shown, Embodiment 1 of the present invention provides a machine room maintenance and overhaul device for a multifunctional mobile work platform, including a box body 1, an installation cavity 13 is provided inside the box body 1, and universal wheels 11 are installed at the lower end of the box body 1 , One side of the box body 1 is provided with a push handle 12, the inner wall of the box body 1 is provided with a mounting plate 2, and the box body 1 is symmetrically provided with two pairs of mounting plates 2 in the width direction, and the mounting plate 2 is provided with a chute 3, the chute 3 is provided with a roller 6, a limit washer 4 is installed on the roller 6, a horizontal support plate 7 is installed on the roller 6, a storage slot 23 is provided in the horizontal support plate 7, a KVM all-in-one machine 8 is installed in the storage slot 23, and the installation cavity The intelligent module 9 and the battery module 10...

Embodiment 2

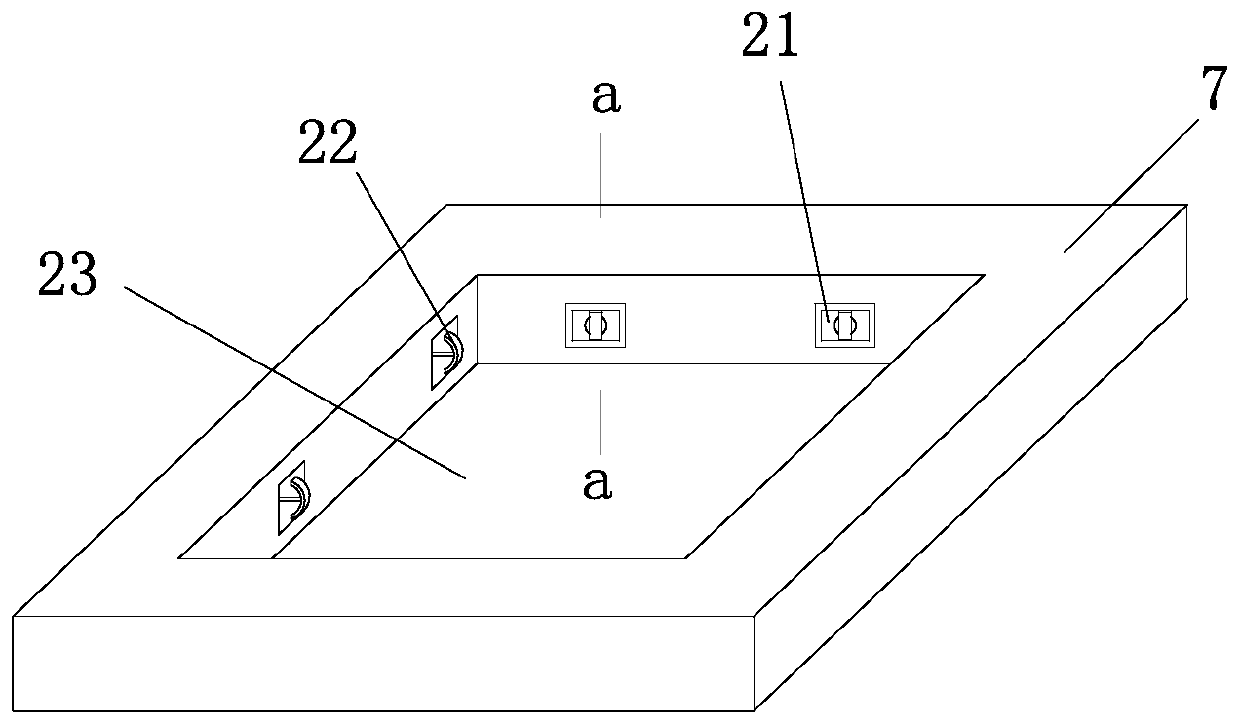

[0036] refer to image 3 and Figure 4The difference between the second embodiment and the first embodiment is that the inner wall of the horizontal supporting plate 7 is provided with a mounting groove 21, and the inner wall of the mounting groove 21 is equipped with a first piston 24, and the first piston 24 is far away from the side of the horizontal supporting plate 7. Piston shaft 25 is installed, the second piston 27 is installed on the side of piston shaft 25 away from the first piston 24, and the limit plate 22 is installed on the side of the second piston 27 away from the piston shaft 25, the first piston 24 and the second piston 27 A spring 26 is provided between them, and the spring 26 is sleeved on the outer circumference of the piston shaft 25 . By establishing the installation groove 21 on the inwall of the horizontal supporting plate 7, the first piston 24, the piston shaft 25 and the limit plate 22 are installed on the inwall of the installation groove 21, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com