Dust removal system for plastic particle production and processing

A plastic particle and dust removal system technology, which is applied in the direction of smoke removal, dispersed particle filtration, dispersed particle separation, etc., can solve the problem of low dust removal rate, and achieve the effect of reducing the requirements and volume of the factory building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

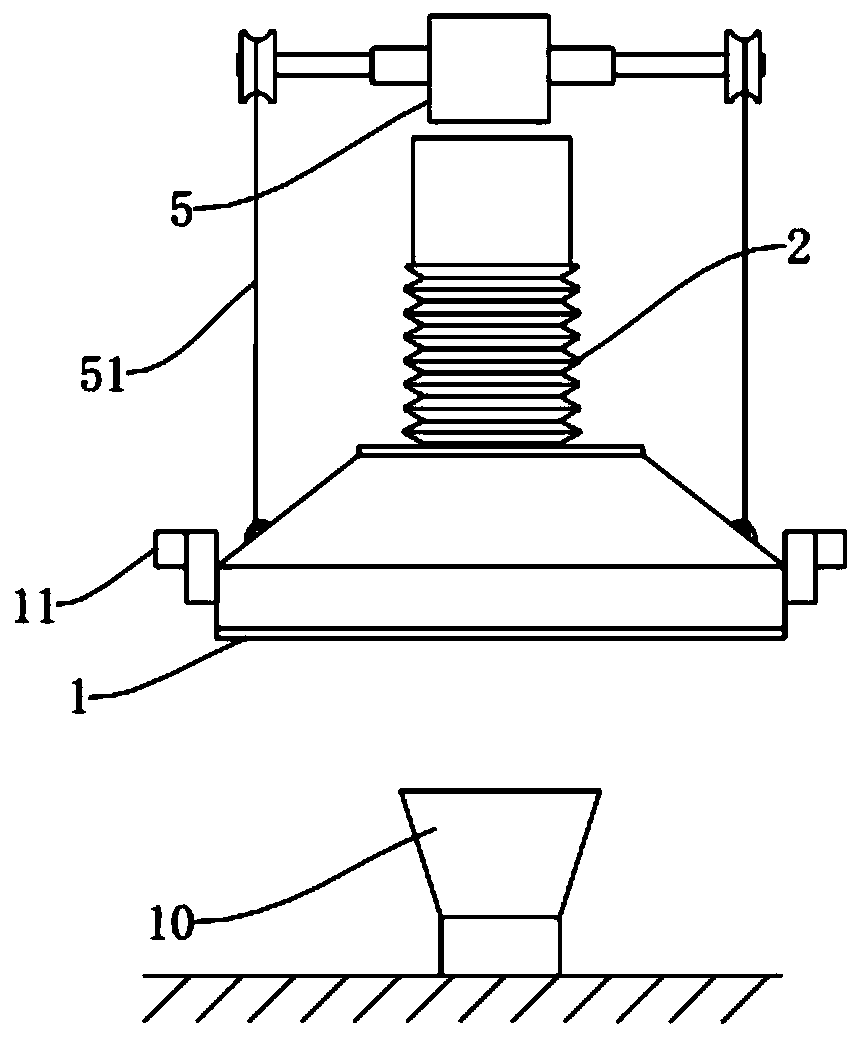

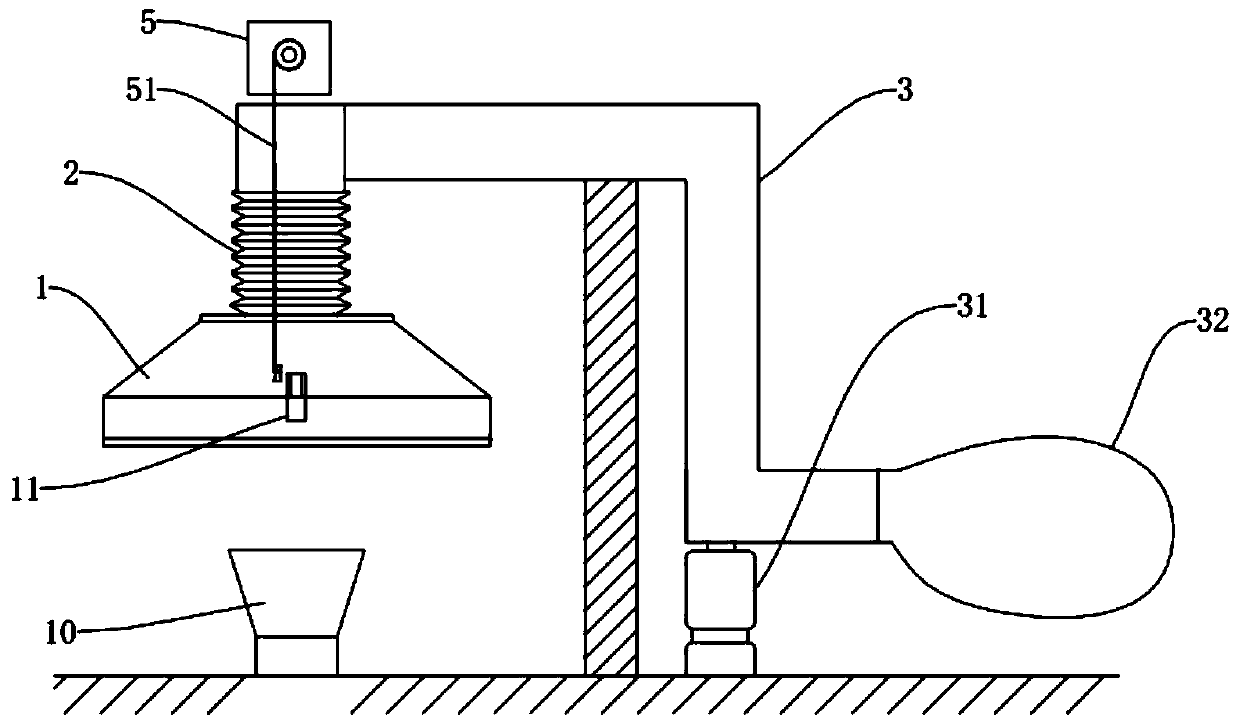

[0031] Dust removal system for the production and processing of plastic granules, such as figure 1 As shown, it includes a dust collection hood 1 and a bracket. The dust collection hood 1 is arranged at 2-2.5 m directly above the feed hopper 10, and is in the shape of an inverted funnel. Sliders 11 are welded on both sides of the dust collection cover 1, and a chute cooperating with the sliders 11 is fixed on the bracket. In order to make the dust collection hood 1 vertically lift and slide relative to the support, the double-axis motor 5 is fixed on the support, and the two output shafts of the double-axis motor 5 are connected with a winding wheel through a key, and a winding rope 51 is wound on the winding wheel. The lower end of the rope 51 is fixed with the outer wall of the dust collection cover 1 . When the motor rotates, the dust collection cover 1 can move up and down.

[0032] The dust collection hood 1 communicates with the telescopic air duct 2 through the flange...

Embodiment 2

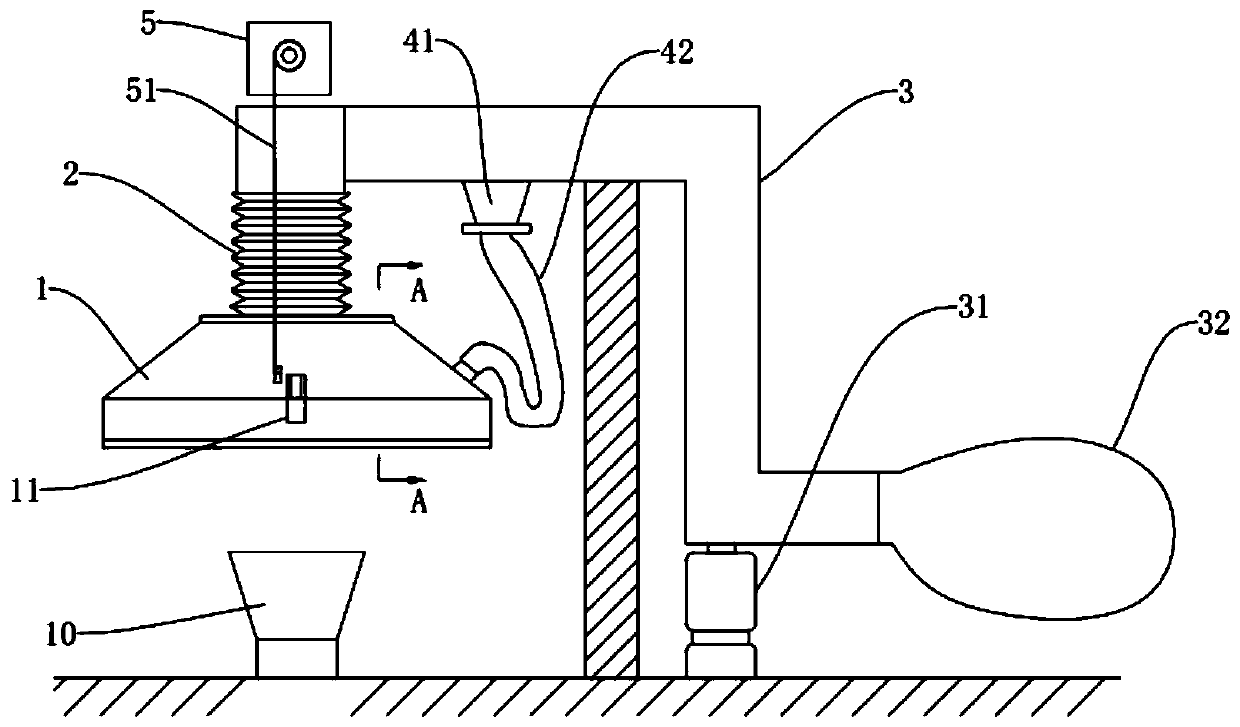

[0036] The difference from the embodiment is that, as Figure 4 As shown, near the suction pipe 43 is bonded to the lower edge of the dust collection hood 1, and the cross section of the near suction pipe 43 is J-shaped. The near suction pipe 43 is provided with a plurality of suction ports 44, and some suction ports 44 face the dust collection hood 1. Inside, some suction ports 44 are facing the outside of the dust collection hood 1 . Near suction pipe 43 is communicated with suction pipe 42, as image 3 As shown, the suction pipe 42 communicates with the auxiliary suction hood 41 , the auxiliary suction hood 41 is funnel-shaped, and the upper end of the auxiliary suction hood 41 communicates with the dust suction air duct 3 through a flange.

[0037] When negative pressure is generated in the dust suction duct 3, the dust suction port 44 can expand the suction area of the dust suction hood 1 in the air during the descent of the dust suction hood 1. After the dust suction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap