DD motor nut rotary feeding device

A technology of nut rotation and feeding device, which is applied in transmission devices, large fixed members, belts/chains/gears, etc. It can solve the problems of low transmission accuracy and achieve the effects of convenient installation, stable driving and reduced driving stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

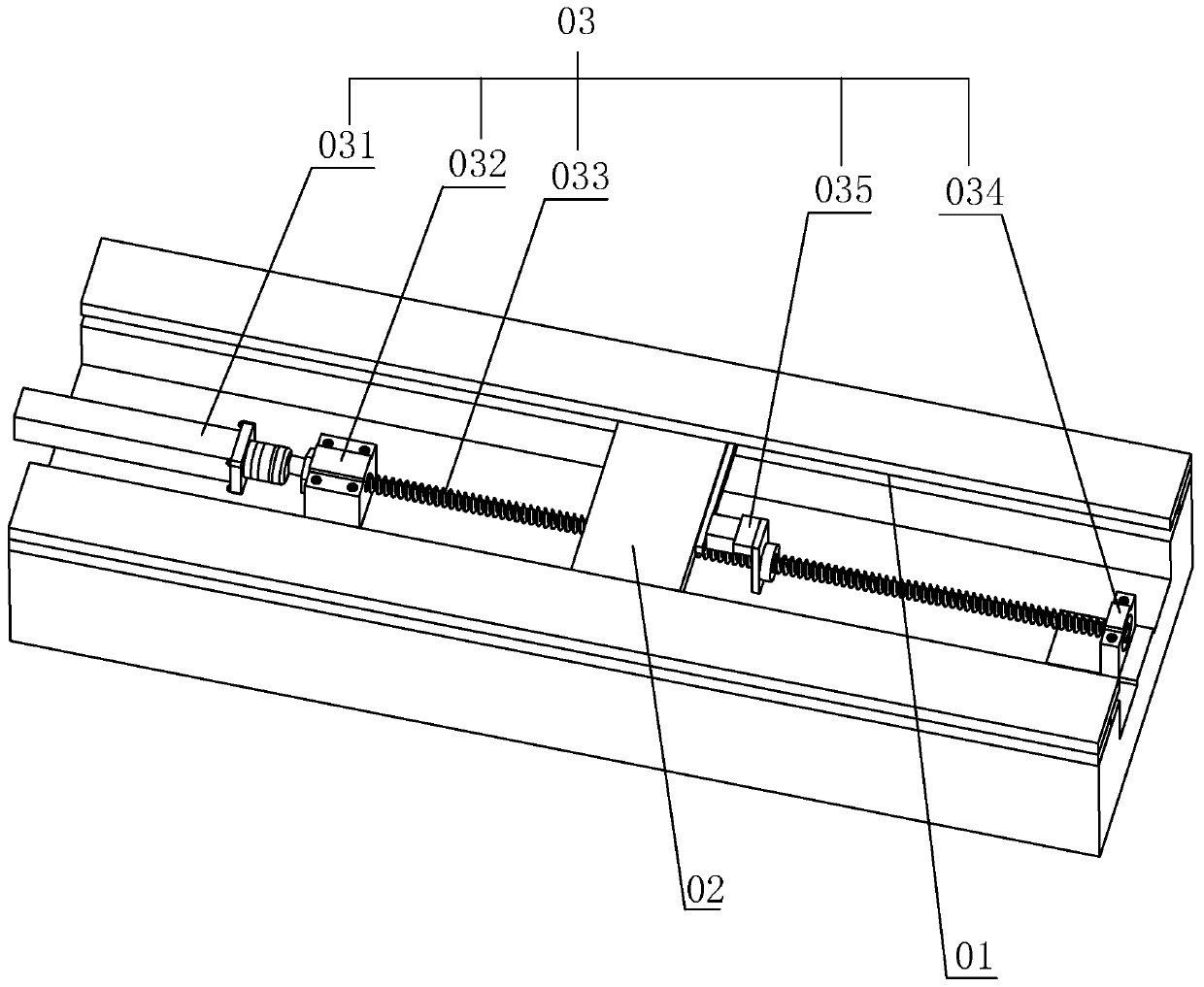

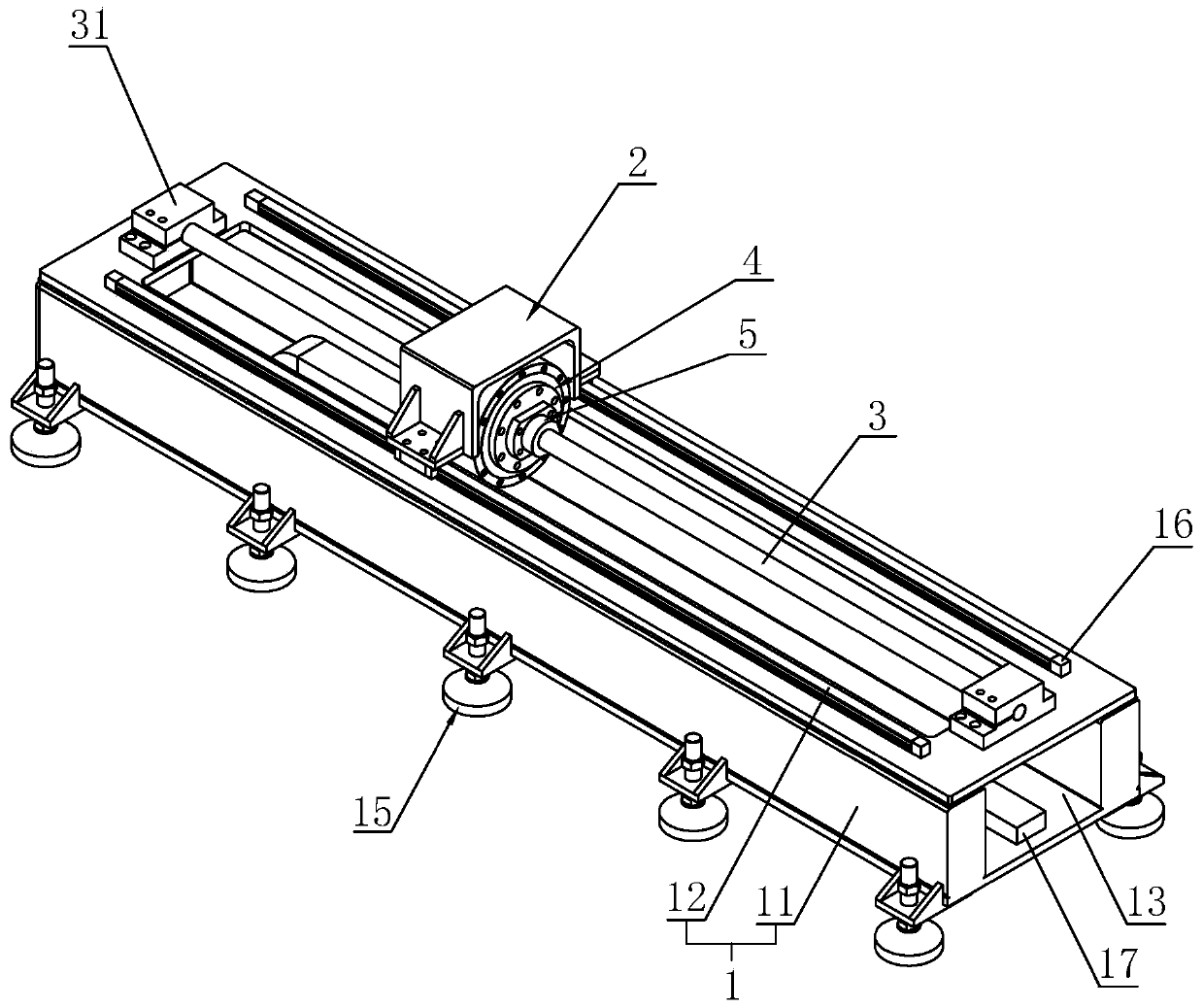

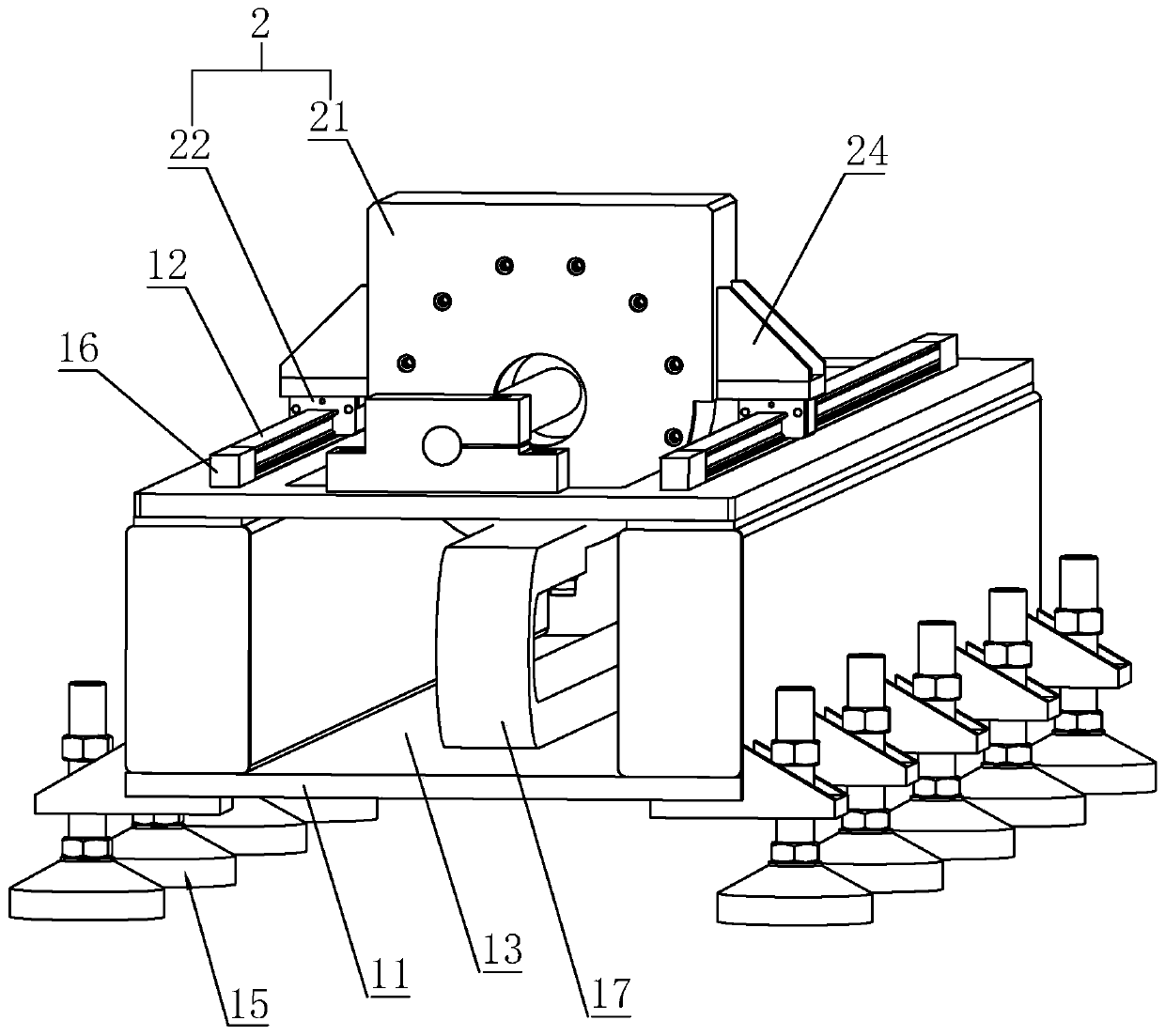

[0040] Refer to background technology figure 1 , the main technical point of the present invention is to integrate the motor 031 and the worktable 02 together, reduce the driving stroke between the motor 031 and the worktable 02, avoid the vibration of the screw rod 033, and improve the driving stability. The specific implementation structure is a DD motor nut rotary feeding device, combined with figure 2 and image 3 It can be seen that it includes a track structure 1 , a feed table structure 2 , a fixed screw rod 3 and a driving structure sleeved on the fixed screw rod 3 for driving the feed table structure 2 to move. The feed table structure 2 is slidably installed on the track structure 1 , and the drive structure is installed in the feed table structure 2 and fixed thereto, so as to realize the integration between the drive structure and the feed table structure 2 . At the same time, the drive structure drives itself to move back and forth along the fixed screw rod 3, ...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that an insulating electrical tank is provided in the installation groove 13, and an electrical connecting piece is provided at the power-connecting end of the driving member 4, and the electrical connecting piece is slidably connected in the insulating electrical tank to continuously receive electricity. . Wherein, the insulating tank is made of insulating materials such as plastic materials, and at the same time, a conductive piece is arranged in the insulating tank, and the connecting piece is always slidingly connected with the connecting piece when sliding, so as to keep the driving member 4 conveniently connected to electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com