Positioning method for mounting cutting roller tooth holders through tooth holder robot

A positioning method and the technology of the roller tooth seat, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems that the cutting head manufacturing accuracy cannot meet the design requirements, and the installation error is large, so as to achieve high-precision manufacturing standards, promote lifting, reduce The time-consuming effect of tooth seat positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

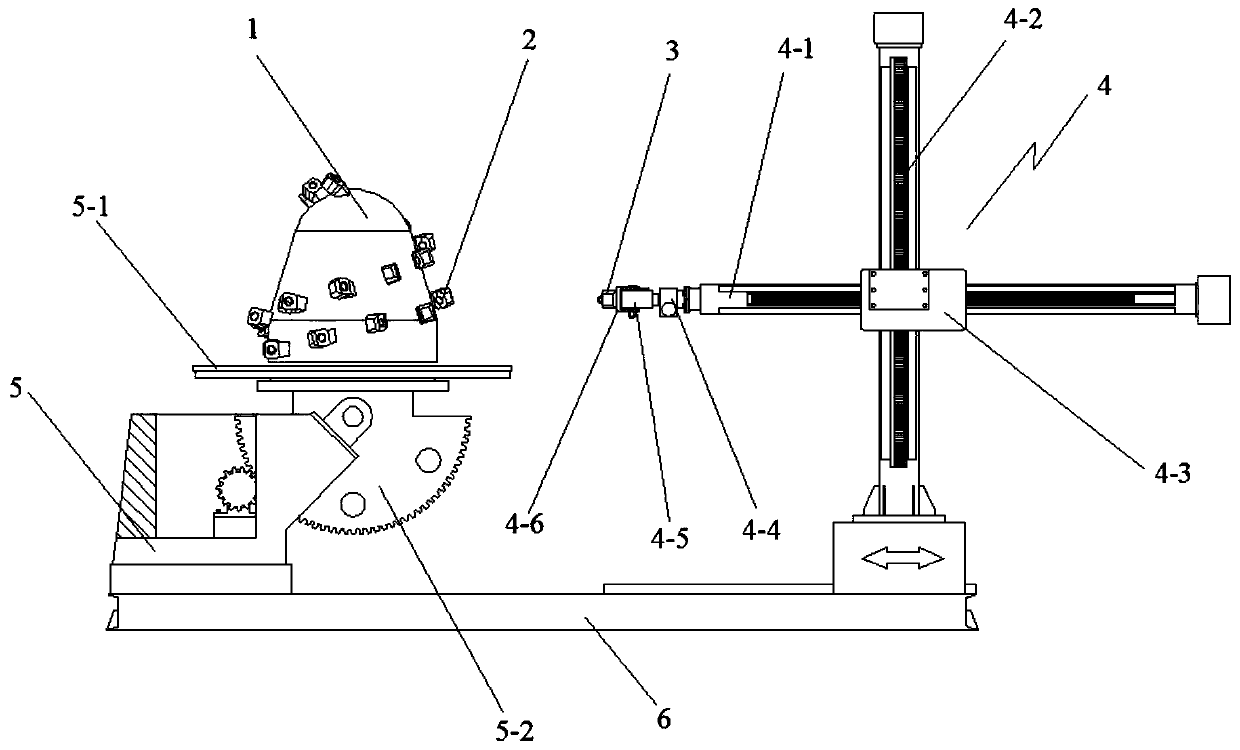

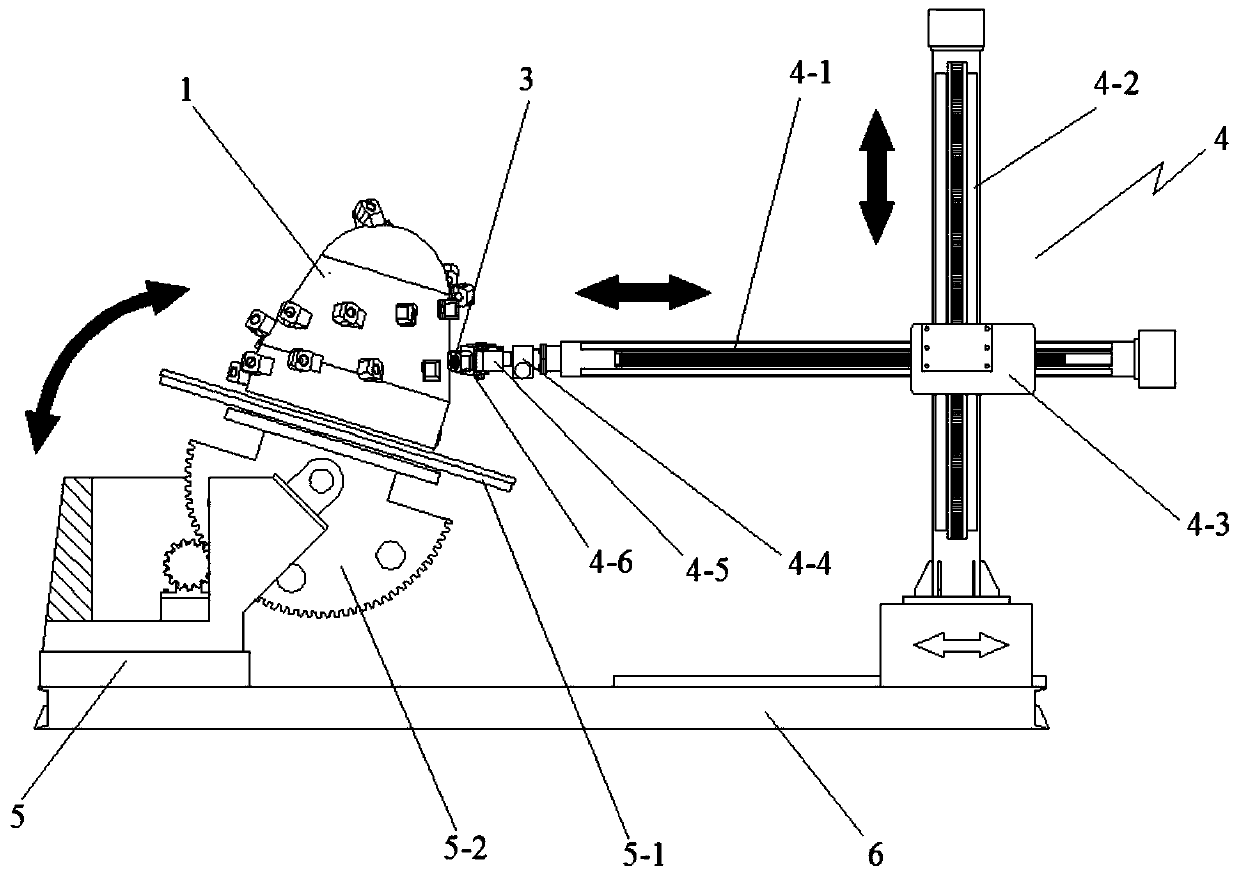

[0016] Such as figure 1 and figure 2 As shown, a positioning method for installing a cutting drum tooth seat by a tooth seat robot in this embodiment includes the following steps:

[0017] 1) Install the tooth seat 3 to be positioned on the tooth seat mounting frame 4-6, and the initial state of the tooth seat 3 to be positioned is that the axis of the tooth seat mounting frame 4-6 and the axis of the horizontal linear guide rail 4-1 are collinear , the tooth seat robot 4 starts to execute the positioning program;

[0018] 2) The turntable 5-1 in the rotation positioning mechanism 5 flips up and down to a predetermined angle along the axis of the overturning gear 5-2 to complete the first spatial orientation of the gear seat 3 to be positioned; at the same time, the turntable 5-1 turns left and right around its own axis Rotate to a position separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com