Chip heat dissipation structure

A chip heat dissipation, chip technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of cost control, radiator space size limitation, etc., to improve production assembly efficiency and increase heat transfer area , Improve the overall cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

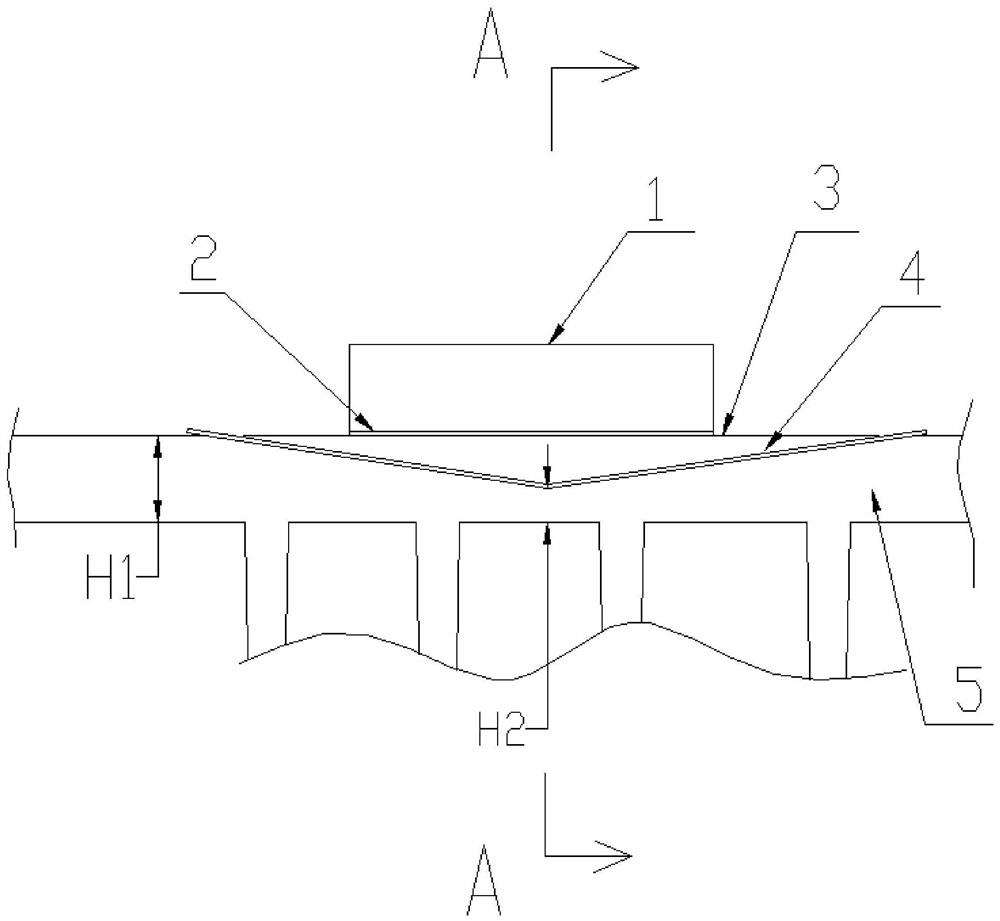

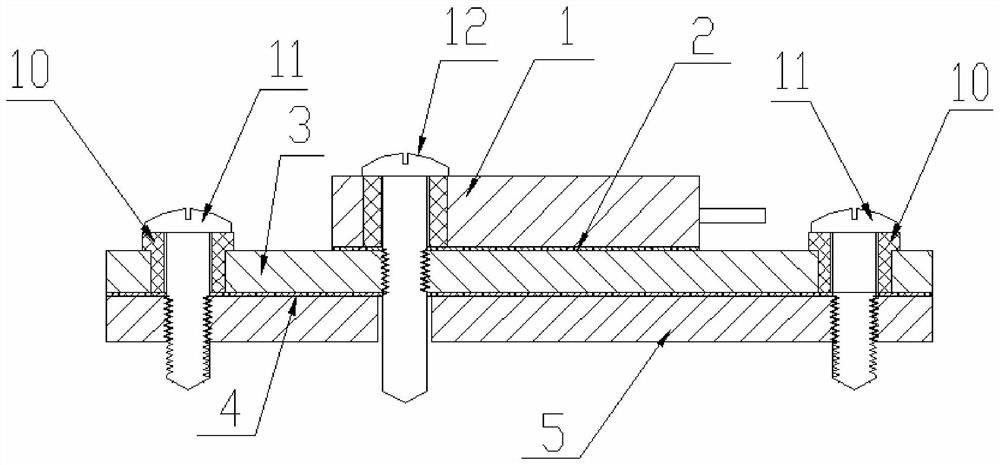

[0041] Implementation Case 1: see figure 1 and figure 2 , the chip 1 (igbt chip) is closely connected to the upper surface of the upper substrate 3 through the thermal conduction layer 2 (silicon grease layer); the material of the upper substrate 3 is the same as that of the lower substrate 5, both of which are aluminum alloy metal. The bottom surface of the upper base 3 is V-shaped, and it is closely connected with the lower base 5 through the insulating heat-conducting gasket 4 (fiber insulating heat-conducting material), and the lower base 5 has a prefabricated matching V-shaped groove. The insulating and heat-conducting gasket 4 is 2 mm to 3 mm beyond the edge of the bottom surface of the upper substrate 3 to ensure effective insulation. The base of the heat sink 9 is a flat plate structure, that is, the thickness is reduced in the groove area corresponding to the upper base 3 . The substrate thickness H1 of the lower substrate 5 is 4 mm, and the substrate thickness at ...

Embodiment example 2

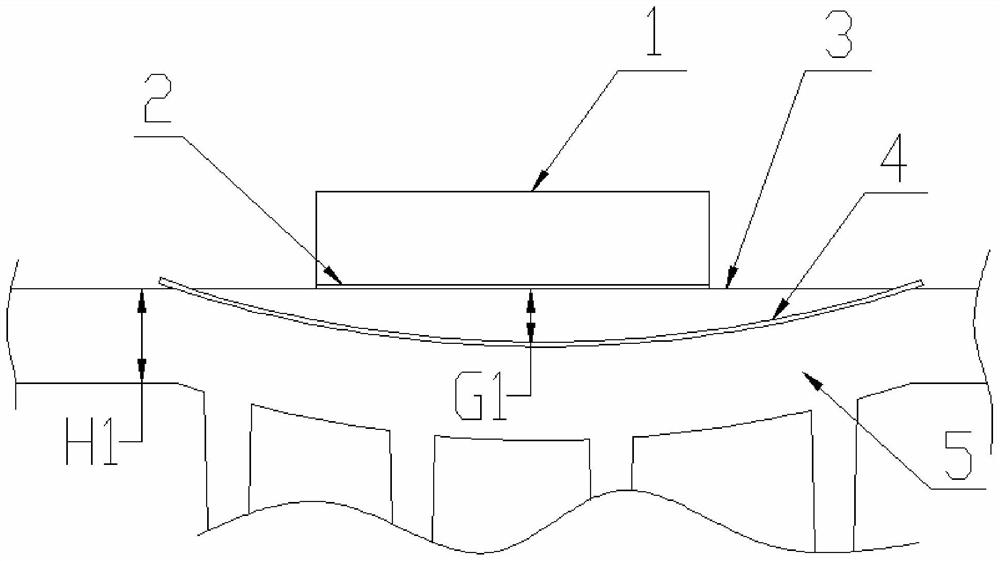

[0043] Implementation Case 2: see image 3 , the chip 1 (igbt chip) is closely connected to the upper surface of the upper substrate 3 through the thermal conduction layer 2 (silicon grease layer); the material of the upper substrate 3 is the same as that of the lower substrate 5, both of which are aluminum alloy metal. The bottom surface of the upper base 3 is an arc-shaped curved surface structure, which is closely connected with the lower base 5 through the insulating heat-conducting gasket 4 (fiber insulating heat-conducting material), and the lower base 5 has a prefabricated matching arc-shaped groove, where the arc-shaped groove is located. The thickness of the position remains consistent with the overall thickness of the substrate, that is, the thickness of the substrate in all regions of the lower base 5 remains unchanged. The insulating and heat-conducting gasket 4 is 2 mm to 3 mm beyond the edge of the bottom surface of the upper substrate 3 to ensure effective insul...

Embodiment example 3

[0045] Implementation Case 3: see Figure 7 , the second chip 6, the chip 1 (igbt chip) and the third chip 7 are sequentially arranged on the heat sink. The second chip 6 is closely connected to the top surface of the lower substrate 5 through the second heat conduction layer 8 (silicon grease layer); the third chip 7 is closely connected to the top surface of the lower substrate 5 through the third heat conduction layer 9 (silicon grease layer). The chip 1 (igbt chip) is closely connected to the upper surface of the upper substrate 3 through the thermal conduction layer 2 (silicon grease layer); the material of the upper substrate 3 is the same as that of the lower substrate 5, both of which are aluminum alloy metal. The bottom surface of the upper base 3 is V-shaped, and it is closely connected with the lower base 5 through the insulating heat-conducting gasket 4 (fiber insulating heat-conducting material), and the lower base 5 has a prefabricated matching V-shaped groove. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com